Joint study by BV and TotalEnergies models health risks associated with shipboard leaks of ammonia compared with LNG

Since the smallest shipboard leaks of ammonia pose serious threats to human health, shipowners will be challenged to safeguard life through enhanced ship design, improved vapour gas processing and greater safety zones than is the case for LNG.

These were some of the key findings that emerged from a preliminary study undertaken by Bureau Veritas (BV) and TotalEnergies that examined ammonia shipboard leaks. Evaluations explored different scenarios regarding the frequency and volume of leaks for single-wall and double-wall containment, as well as during bunkering operations. The study accounted for the thermodynamic properties of leaked ammonia and used high-end engineering tools to determine the changing flows and concentrations of leaks.

For the study, BV leveraged its extensive experience with LNG. Its newly released AMMONIA PREPARED notation and Rule Note NR 671 for ammonia as fuel addresses the safety aspects of managing ammonia in storage tanks, fuel-piping systems and during bunkering.

While ammonia has been carried by ships for decades, it has never been used as a marine fuel. Carbon-free, green ammonia — produced through electrolysis — is viewed as a potential zero-emissions fuel to aid shipping’s decarbonisation. But ammonia is extremely toxic, posing serious health risks to crew and passengers.

Stringent leak management

With ammonia-powered engines and propulsion systems still under development, BV and TotalEnergies began by benchmarking ammonia’s problematic concentrations in air, comparing them with LNG.

An LNG-fuelled tanker served as the model for the comparison and showed a stark contrast between the two fuels. LNG becomes dangerous at its lower flammability limit, around 50,000 parts per million (ppm), while ammonia has negative health effects at only 30 ppm when permanently exposed, or around 300 ppm when exposed for one hour.

“Ammonia has negative health effects at only 30 ppm when permanently exposed”

Based on this, BV cautioned that unless modifications are made, safety distances should be much greater for ammonia than LNG. This justified the approach of BV NR671, which requires more stringent leak management on board and vapour gas processing to avoid even small leaks reaching manned areas.

Key areas studied included: preliminary estimates of the ammonia concentration in case of leaks (eg the double-wall pipes’ annular space and fuel preparation room); guidance to determine the size of associated safety systems (eg ventilation, vapour-processing systems); effects of leaks in the engineroom, in the case of ammonia passing through the storage tank’s primary and secondary barriers; size of safety zones around vent masts for ships not equipped with a vapour-processing system; and health risks to persons in the area exposed to ammonia leaks.

Ideally, technology will evolve to eliminate ammonia leaks completely. Until then, leak mitigation and treatment remain the best course of action for shipowners and designers, says BV.

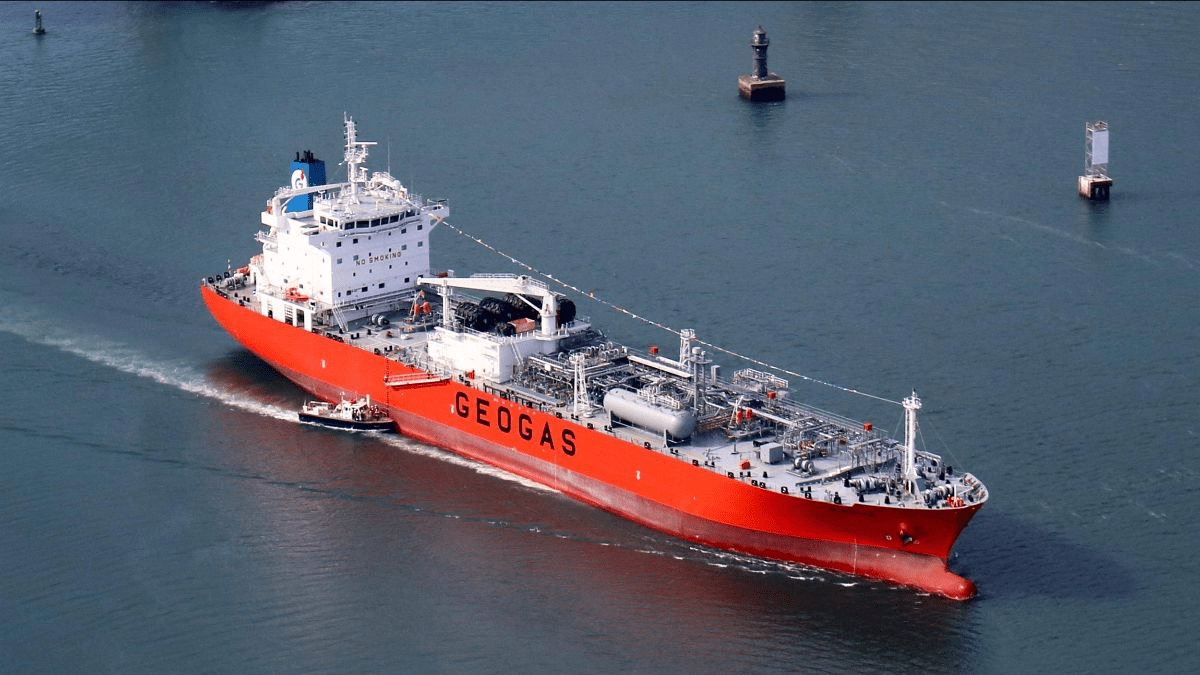

BV is helping Jiangnan Shipyard develop the world’s largest very large ammonia carrier and issued its AMMONIA PREPARED notation to two 40,000-m3 LPG carriers being built for Geogas.