New range of pumps introduced in response to role of liquefied gases in energy transition

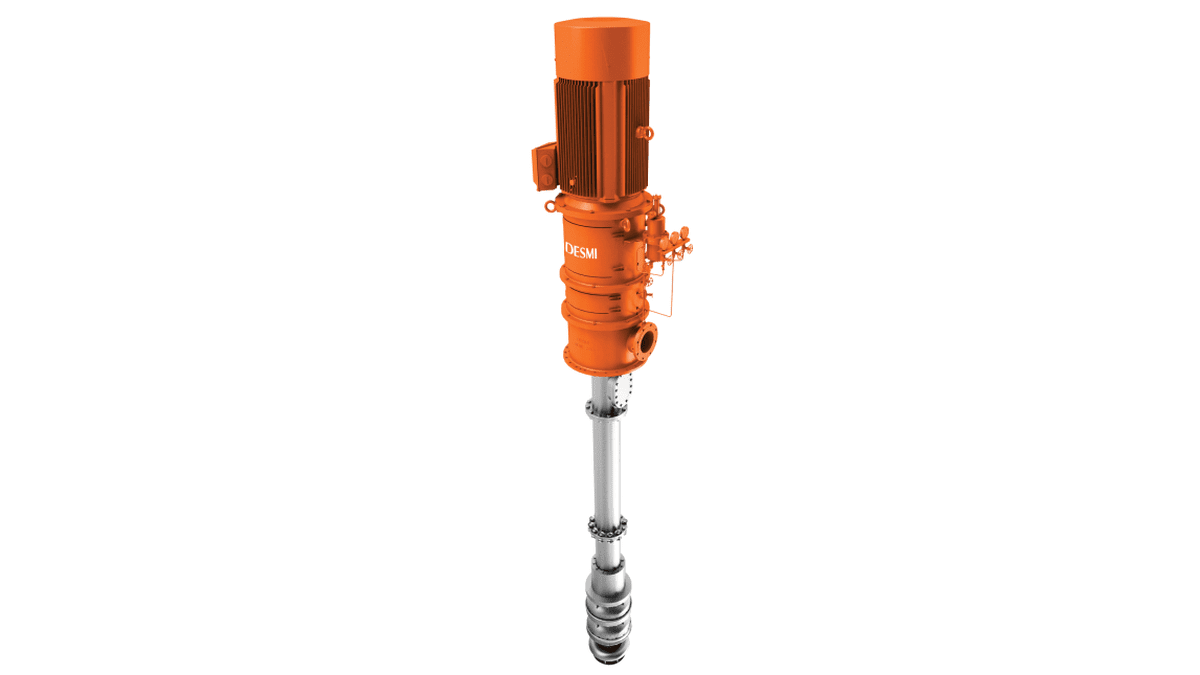

Drawing on its past pump experience, DESMI is relaunching its range of cargo pumps for liquefied gas, improving their efficiency and reducing the number of components.

But as DESMI gas systems global sales manager Martin Bro points out, the relaunch to the gas carrier and tanker market is also being driven by the global energy transition. “Our NDW range of cargo pumps is designed for LPG and LEG applications, but that’s just the start,” explains Mr Bro. “The marine business is evolving fast: to reduce carbon emissions, many marine engines are already fuelled by LPG and LEG today, and we expect that this tendency will only increase in the years to come.”

Gas cargoes, too, will likely change. “We’ll probably see an increased need for liquefied CO2 transportation,” adds Mr Bro. “The evolution of carbon capture and storage technology means that CO2 needs to be shipped to underground storage locations. So, both in terms of fuels and cargo, gas will change shipping, and our cargo pumps support this evolution: they will be developed to handle LNG, CO2, and other liquefied gases, and they can be adapted for use as gas fuel pumps. In short, they will be able to fulfil all future liquefied gas-handling requirements”.

DESMI has been in the cargo pump business before, manufacturing and installing 250+ cargo pump solutions on carriers from the mid-1990s to around 2010. The new NDW range marks a return to the market of a proven pump range. For the relaunch, DESMI combines its experience with the company’s general expertise in marine pump design and adds a range of technological advances.

“Gas will change shipping, and our cargo pumps support this evolution”

“Over the years, we have quite simply become much better at building pumps, and a new DESMI cargo pump is superior to an old one,” says Mr Bro. “To take just one example, our design processes have improved through the use of state-of-the-art design and calculation tools.” He says using CFD and stainless-steel casting simulations, “we have achieved a highly efficient pump design, customised to our customers’ exact requirements. In fact, the efficiency of our centrifugal cargo pumps is approximately 80%.”

DESMI says the pumps feature a well-proven double-shaft seal to mitigate any leakage, a reduced number of impeller stages, easy installation and maintenance and offer the possibility to rotate the shaft counter direction in the case of ice blocking.

While the new cargo pumps are designed and developed at DESMI headquarters in Denmark, they are manufactured at its production facilities in China, close to shipyards where the pumps will be installed; this translates to shortened delivery times.

“Not only is sea transportation of liquefied gas still important; it looks set to be an integral part of the green transformation,” concludes Mr Bro. “Our relaunched range of cargo pumps is ready to support companies now and in future – from LPG to LNG and beyond.”