1. Port Rules and Regulations

1.1. Vessel Entry/Exit Requirements

– Advance notice: Vessels must submit entry/exit notifications to Shiogama Port Authority at least 24 hours prior to arrival/departure (Japan Port Regulations Act Article 56).

– Mandatory documents: Ship registry, crew list, cargo manifest, and safety inspection certificates (SOLAS Chapter V Regulation 11).

– Restricted areas: Designated anchorage zones marked in official nautical charts (JCG Notice No. 12/2021).

1.2. Navigation Rules

– Speed limit: 8 knots within port limits (Shiogama Port Ordinance §3-2).

– Right-of-way: Fishing vessels have priority in operational areas (Maritime Traffic Safety Act Article 18).

– Prohibited actions: Overtaking in channels under 200m width (IMO Resolution A.857(20)).

1.3. Cargo Operations

– Hazardous materials: Requires separate permit from Miyagi Prefecture (Fire Service Act Article 10).

– Grain handling: Dust control measures mandatory (Industrial Safety and Health Ordinance Article 88).

– Crane operations: Maximum wind speed limit of 15m/s (JIS F 8001 standard).

2. Compliance and Enforcement

2.1. Inspection Regime

– Port State Control: Tokyo MOU inspection criteria apply with 15% annual inspection rate (2023 PSC report).

– Safety equipment: Monthly lifeboat drills verified by logbook stamps (SOLAS Chapter III Regulation 19).

– Oil record book: Mandatory entries for all bunkering operations (MARPOL Annex I Regulation 17).

2.2. Penalties

– Navigation violations: Fines up to ¥500,000 for speed limit breaches (Port Regulations Law Article 45).

– Pollution offenses: Criminal prosecution for deliberate discharge (Water Pollution Control Law Article 30).

– Documentation fraud: 3-month port entry ban (Customs Act Article 108-2).

2.3. Emergency Protocols

– Oil spills: Immediate reporting to 118 (Japan Coast Guard emergency line).

– Man overboard: Mandatory VHF Channel 16 alert + flare deployment (COLREG Rule 35).

– Fire response: Port fire brigade activation within 7 minutes (Shiogama Port Safety Plan 2022).

3. Crew Safety Provisions

3.1. Personal Protection

– Hard hats: Required during all cargo operations (ILO Convention C152 Article 16).

– Life jackets: Type I PFDs mandatory on open decks (Ship Safety Act Article 42).

– Gas detectors: Must be carried in enclosed spaces (SOLAS XI-1/7).

3.2. Working Hours

– Maximum 14 hours/day with 10 consecutive rest hours (MLC 2006 Standard A2.3).

– Night work premium: 25% additional pay (Japanese Labor Standards Act Article 37).

3.3. Medical Support

– Port clinic: Available 24/7 with decompression chamber (Shiogama City Health Dept. data).

– Emergency transport: Helicopter medevac coordinated via JRCC Tokyo.

4. Ship Operator Requirements

4.1. Financial Guarantees

– Oil pollution insurance: Minimum ¥1 billion coverage (CLC 1992).

– Port dues deposit: 120% of estimated fees (Ports and Harbors Act Article 22).

4.2. Waste Management

– Garbage logbook: Separate sections for food/plastic/operational waste (MARPOL Annex V).

– Sludge disposal: Only at licensed reception facilities (Waste Management Law Article 6).

4.3. Crew Change Procedures

– Immigration clearance: Must be completed at Sendai Airport immigration office.

– COVID-19 measures: PCR test within 72 hours of arrival (MHLW Notice 0825).

5. Environmental Regulations

5.1. Air Emissions Control

– Sulfur cap: 0.1% sulfur content limit for fuels at berth (Air Pollution Control Act Article 18-2).

– Auxiliary engines: Shore power connection mandatory after 2 hours at dock (Port Regulations Law Amendment 2021).

– NOx monitoring: Continuous emissions recording for vessels >5,000 GT (IMO Tier III requirements).

5.2. Ballast Water Management

– Exchange requirement: Minimum 200nm from shore for mid-ocean exchange (BWM Convention D-1 standard).

– Treatment systems: USCG-type approved systems required for US-bound vessels.

– Sampling ports: Mandatory installation for vessels built after 2020 (Japan BWM Guidelines).

6. Security Measures

6.1. ISPS Code Implementation

– Security levels: MARSEC Level 1 enforced with 24/7 guard patrols (ISPS Code Part A/4.26).

– Restricted areas: Electronic access control for all port facilities (Transport Security Act Article 14).

– Drills: Quarterly security exercises including bomb threat scenarios.

6.2. Cyber Security

– ECDIS updates: Weekly vulnerability patches required (ClassNK Guidelines 2022).

– Network segregation: Operational technology systems must be air-gapped (IEC 61162-460).

7. Special Cargo Handling

7.1. Dangerous Goods

– Class 1 explosives: Requires police escort during transport (Explosives Control Law Article 9).

– Radioactive materials: Prior notification to Nuclear Regulation Authority 72 hours in advance.

– Stowage requirements: Segregation as per IMDG Code Chapter 7.2.

7.2. Refrigerated Containers

– Temperature logs: 1-hour interval recordings during port stay (ATP Agreement Annex 1).

– Emergency power: Backup generators tested monthly (JIS C 8283-1).

8. Port Services

8.1. Pilotage

– Compulsory areas: Entire port waters (Pilotage Law Article 4).

– Tug requirements: Minimum 2 tugs for vessels >20,000 DWT (Shiogama Port Operation Rules).

8.2. Mooring

– Bollard capacity: 150-tonne SWL at main berths (Port Facility Register 2023).

– Line handlers: Certified personnel only (Japan Harbor Transportation Association).

9. Weather Restrictions

– Typhoon procedures: Evacuation order issued when sustained winds exceed 25m/s.

– Tsunami warning: Immediate departure required for Alert Level 3 (JMA Warning System).

– Ice conditions: Anti-icing spray available at Berths 5-7 (December-March).

10. Local Ordinances

– Noise limits: 75 dB(A) during night hours (2200-0600) (Noise Regulation Law).

– Light pollution: Restricted use of floodlights after 2300 hrs.

– Fishing zones: 500m exclusion around active fishing gear (Fisheries Coordination Regulation).

11. Vessel Traffic Services (VTS)

11.1. Communication Protocols

– Primary channel: VHF Channel 12 for port operations (ITU-R M.1084).

– Reporting points: Mandatory position reports at 38°18’N 141°02’E (Shiogama VTS Circular 2022-4).

– Language: English or Japanese communications required (IALA V-128).

11.2. Traffic Separation

– Inbound/outbound lanes: 200m width maintained (COLREG Rule 10).

– Fishing vessel corridor: 1nm wide zone along 100m depth contour.

– Prohibited anchoring: Within 0.5nm of channel markers (Notice to Mariners No. 35/2023).

12. Port Infrastructure

12.1. Berth Specifications

– Maximum LOA: 250m at Main Wharf (Port Facility Certificate 2023).

– Draft limitations: 13.5m at high tide (Tide Tables Vol. 6).

– Bollard spacing: 25m intervals with 200t capacity (Class NK Hull Rules).

12.2. Utilities

– Potable water: 50t/hour supply capacity at all berths.

– Bunkering: Only licensed providers permitted (Fuel Quality Control Law).

– Waste reception: Fixed piping for oily waste at Berths 3-6.

13. Crew Welfare

13.1. Shore Leave

– Immigration clearance: Required for all crew (Immigration Control Act Article 22).

– Curfew: 0100-0500 hrs for non-officers (Port Security Ordinance).

– Prohibited areas: 500m radius from residential zones.

13.2. Provisions

– Food safety: USDA/FDA equivalent standards enforced (Food Sanitation Act).

– Cash limits: Maximum ¥100,000 per crew member (Foreign Exchange Law).

14. Salvage & Wreck Removal

– Immediate reporting: Within 1 hour of incident (Marine Accident Inquiry Act).

– Liability: Strict liability for obstruction removal (Ports and Harbors Act Article 37).

– Insurance: Minimum ¥500 million coverage required.

15. Ice Navigation (Winter Operations)

– Ice class requirements: JIS IA Super for December-February.

– Escort tugs: Mandatory for vessels without icebreaking capability.

– Speed reduction: 50% normal speed during ice conditions.

16. Dangerous Weather Contingency Plans

16.1. Typhoon Preparedness

– Evacuation order: Issued when sustained winds exceed 30m/s (JMA Typhoon Warning Criteria)

– Mooring arrangements: Double lines + spring lines required for all vessels >5,000GT

– Emergency towage: 2 harbor tugs on standby during typhoon season (July-October)

16.2. Tsunami Response

– Warning levels: Immediate departure required for Level 3 warnings (3m+ wave forecast)

– Safe zones: Designated deep-water holding areas at 38°25’N 141°15’E

– Post-event inspection: Mandatory hull damage assessment before re-entry

17. Port State Control Inspection Focus Areas

17.1. High-Risk Items

– Fire dampers: 100% operability test for vessels >10 years old

– Emergency generator: Must sustain full load for 3 hours (SOLAS II-1/43)

– Bridge equipment: Backup magnetic compass deviation <3°

17.2. Documentation Checks

– Continuous Synopsis Record: Original copy with all amendments

– Garbage Management Plan: Updated to reflect 2023 MEPC resolutions

– Ballast Water Record Book: Complete entries for last 24 months

18. Special Operations

18.1. Heavy Lift Procedures

– Wind limitations: Max 10m/s for lifts >100 tons

– Notifications: 72-hour advance notice to harbor master

– Exclusion zones: 50m radius during load transfers

18.2. Night Navigation

– Lighting requirements: Additional working lights for cargo operations

– Speed restriction: 5 knots in inner harbor after 2000 hrs

– Pilot exemption: Not permitted between 2300-0500 hrs

19. Bunkering Regulations

19.1. Fuel Quality Control

– Sampling: Triple-seal MARPOL samples required

– Documentation: BDN must include sulfur content (0.1% max)

– Contingency plan: SOPEP equipment deployed during operations

19.2. Barge Requirements

– Double hull: Mandatory for all bunker vessels

– Communication: Dedicated VHF channel monitored 24/7

– Spill response: 50m boom deployment capacity

20. Port Dues and Charges

20.1. Fee Structure

– Basic tonnage fee: ¥32.5 per GT (2024 tariff)

– Environmental surcharge: 15% for vessels without scrubbers

– Overtime charges: 200% for holidays (Japanese national calendar)

20.2. Payment Methods

– Advance payment: Required for vessels with prior PSC deficiencies

– Accepted currencies: JPY, USD, EUR (daily BOJ rate)

– Electronic transfer: SWIFT code SHIOJPJT

21. Ship Repair and Maintenance Regulations

21.1. Dry Dock Operations

– Hot work permits: Required for all welding operations (Japan Industrial Safety Standards)

– Environmental containment: 100% impermeable sheeting under repair areas

– Waste disposal: Separate collection for paint chips and blasting media

21.2. Underwater Inspections

– Diver certification: JISF Class 2 minimum for hull inspections

– Current limits: Operations prohibited above 1.5 knot currents

– Reporting: Hull damage findings within 24 hours to ClassNK

22. Crew Training Requirements

22.1. Port-Specific Familiarization

– Emergency exits: Must know all shore-side evacuation routes

– Pollution response: Annual oil spill drill certification required

– Cultural awareness: Basic Japanese port etiquette training

22.2. Specialized Certifications

– Hazardous cargo: IMDG Code refresher every 2 years

– Mooring operations: SAMI Level 1 for deck officers

– Cold weather: Ice navigation course for winter entries

23. Customs and Immigration Procedures

23.1. Clearance Timeline

– Cargo declarations: Submit 48 hours pre-arrival (Customs Law Article 67-2)

– Crew processing: Minimum 4 hours for full crew manifest verification

– Bonded stores: Seals inspected by customs canine unit

23.2. Restricted Items

– Pharmaceuticals: Maximum 30-day supply per crew member

– Cash declarations: Required above ¥1 million equivalent

– Cultural artifacts: Export permits for antique purchases

24. Port Security Levels

24.1. MARSEC Level Implementation

– Level 1: Standard 24/7 patrols with random vehicle checks

– Level 2: Additional 50% security personnel deployment

– Level 3: Armed JCG boarding teams for high-risk vessels

24.2. Access Control

– Biometric screening: Required for all shore personnel

– Vehicle barriers: Crash-rated bollards at terminal entrances

– Waterside patrol: Armed boats during MARSEC Level 2+

25. Anchorage Regulations

25.1. Designated Areas

– Primary anchorage: 38°20.5’N 141°05.0’E (max 15 vessels)

– Emergency anchorage: 38°22.0’N 141°07.5’E (draft <10m)

– Prohibited zones: 1nm radius around submarine cables

25.2. Anchoring Procedures

– Watchkeeping: Continuous bridge watch required

– Drag monitoring: GPS anchor alarm with 0.1nm threshold

– Emergency signals: Red flares for dragging anchor

26. Marine Pollution Prevention

26.1. Oil Spill Response

– Reporting threshold: Immediate notification for spills >100 liters (MARPOL Annex I)

– Containment equipment: Port maintains 800m of boom capacity

– Dispersant use: Requires pre-approval from Miyagi Prefecture

26.2. Sewage Discharge

– Treatment standards: IMO MEPC.227(64) compliant systems only

– No-discharge zone: Within 3nm of port entrance buoys

– Holding tanks: Mandatory for vessels >400GT built after 2010

27. Vessel Equipment Requirements

27.1. Mandatory Gear

– Local charts: ENC cells JP311110 and JP311120 (latest edition)

– Mooring lines: Minimum 8 synthetic ropes for vessels >150m LOA

– Gangways: ISO 5488 compliant with safety nets

27.2. Communication Systems

– Backup power: 6-hour capacity for VHF radios

– NAVTEX receiver: Continuous monitoring on 518 kHz

– AIS: Transponder must remain active at all times

28. Port Health Services

28.1. Medical Facilities

– Quarantine station: 24/7 operations with PCR testing

– Decompression chamber: Available within 90 minutes notice

– Pharmacy: Controlled substances require special permits

28.2. Sanitation Controls

– Vector control: Mandatory insecticide treatment for certain routes

– Food inspection: USDA/FDA equivalent standards enforced

– Waste disposal: Medical waste incinerator on-site

29. Small Craft Regulations

29.1. Pleasure Vessels

– Speed limit: 5 knots within 200m of commercial docks

– Prohibited areas: 100m exclusion around cargo operations

– Safety gear: VHF radio and GPS mandatory >1nm offshore

29.2. Fishing Boats

– Right-of-way: Commercial vessels have priority in channels

– Gear marking: Fluorescent buoys required for nets

– Night operations: All-around white light when stationary

30. Port Authority Contacts

30.1. Emergency Numbers

– Coast Guard: Dial 118 from any ship phone

– Medical Emergency: +81-22-367-0110 (Shiogama Hospital)

– Pollution Reporting: VHF Channel 16/70

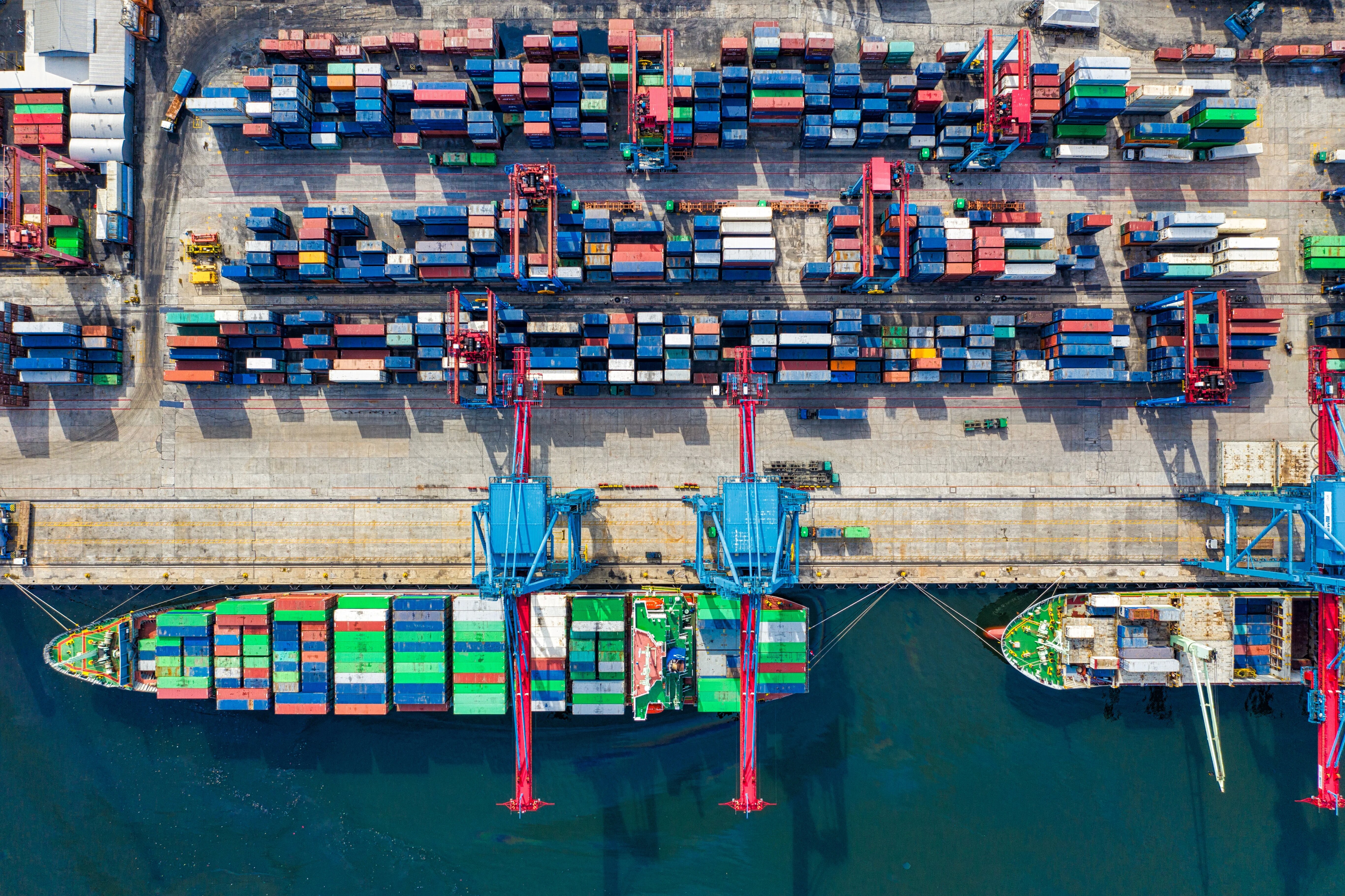

31. Cargo Handling Standards

31.1. Container Operations

– Stacking limits: 5 high for 20′, 4 high for 40′ containers (CTU Code 2022)

– Lashing equipment: DIN/ISO standard twistlocks required

– Wind restrictions: Operations cease at sustained 15m/s winds

31.2. Bulk Cargo Procedures

– Dust suppression: Water spray mandatory during loading

– Trim requirements: Max 5° list during operations

– Sampling: Independent surveyor for grade verification

32. Navigation Aids

32.1. Channel Markings

– Light characteristics: Green FL4s 10s for port side marks

– Buoy spacing: 500m intervals in main channel

– AtoN maintenance: Daily verification checks by JCG

32.2. Electronic Navigation

– ECDIS updates: Weekly Notice to Mariners patches

– Radar overlay: Required for entry in visibility <1nm

– DGPS service: MSAS coverage available 24/7

33. Port Entry Requirements

33.1. Pre-Arrival Documentation

– 96-hour notice: Complete e-Declaration (JP-SINGLE WINDOW)

– Crew list: Biometric data for all personnel

– Cargo manifest: Customs-approved format only

33.2. Special Permits

– Oversized loads: Route survey required 7 days prior

– Night entry: Pilot discretion for vessels >200m LOA

– Hazardous materials: Fire department escort mandatory

34. Tug Services

34.1. Assignment Rules

– Minimum power: 60t bollard pull for vessels >50,000 DWT

– Standby position: 1nm NE of breakwater in readiness

– Emergency response: 15-minute deployment capability

34.2. Operational Limits

– Weather thresholds: Max 35kt winds for assist

– Light conditions: Minimum 1 lux for night ops

– Current restrictions: No operations >3 knots

35. Port Facility Maintenance

35.1. Infrastructure Checks

– Fender inspection: Quarterly load testing

– Depth monitoring: Weekly multi-beam surveys

– Lighting systems: LUX measurements at all berths

35.2. Access Systems

– Gangway rating: Minimum 500kg SWL

– Safety nets: Deployed during all transfers

– Fall protection: OSHA-equivalent harnesses

36. Dangerous Goods Handling

36.1. Classification & Storage

– IMDG segregation: Minimum 50m separation for Class 1 materials

– Explosive zones: Designated Area D-12 with blast walls

– Temperature control: Continuous monitoring for Class 4.1

36.2. Emergency Protocols

– Evacuation radius: 500m for UN1202 incidents

– Firefighting foam: Alcohol-resistant type for polar solvents

– Medical response: HAZMAT-trained teams on 10-minute standby

37. Port Lighting Requirements

37.1. Operational Areas

– Minimum illumination: 200 lux at cargo transfer points

– Color temperature: 4000-5000K for color recognition

– Emergency lighting: 1 hour autonomy at 50 lux

37.2. Navigation Lighting

– Leading lights: 15° sector visibility maintained

– Obstruction lights: FAA Type L-864 for cranes

– Backup power: 8-hour battery for critical aids

38. Vessel Speed Limits

38.1. Channel Restrictions

– Inner harbor: 6 knots within 200m of berths

– Turning basins: 4 knots during vessel maneuvers

– Anchorage areas: 3 knots near moored vessels

38.2. Special Conditions

– Low visibility: 5 knots maximum when <500m visibility

– Night operations: 50% normal speed after sunset

– Tidal currents: Speed-over-ground monitoring required

39. Port Communication Protocols

39.1. Standard Procedures

– Initial contact: VHF Ch 12 with vessel particulars

– Status updates: Hourly position reports at anchor

– Emergency channels: Ch 16 primary, Ch 70 DSC

39.2. Digital Systems

– Port MIS: Web-based cargo declarations

– AIS messaging: For berthing instructions

– ETA updates: Automated via XML feeds

40. Environmental Monitoring

40.1. Air Quality

– Continuous sensors: PM2.5, SOx, NOx measurements

– Emission limits: 0.1% sulfur for at-berth operations

– Data reporting: Monthly submissions to PMDA

40.2. Water Quality

– Sampling points: 8 harbor locations

– Test frequency: Bi-weekly for hydrocarbons

– Discharge standards: <5ppm oil content

41. Vessel Traffic Services (VTS)

41.1. Reporting Points

– Outer approach: 38°18.0’N 141°02.0’E (12nm from port)

– Pilot boarding: 38°20.5’N 141°04.5’E (1nm NE of breakwater)

– Final approach: 38°22.0’N 141°06.0’E (channel entrance)

41.2. Monitoring Requirements

– AIS transponder: Continuous transmission mandatory

– Speed verification: Radar checks at each reporting point

– Draft confirmation: Verified against tide tables

42. Port Facility Security

42.1. Access Control

– Biometric screening: Palm vein authentication for all personnel

– Vehicle inspection: Under-carriage mirrors and x-ray

– Waterside barriers: Floating booms at sensitive areas

42.2. Surveillance Systems

– Camera coverage: 100% of operational areas

– Analytics: AI-based anomaly detection

– Retention period: 90 days for all footage

43. Ice Navigation Procedures

43.1. Winter Operations

– Ice class requirements: JIS Class IC minimum Dec-Mar

– Tug escort: Mandatory for non-ice strengthened vessels

– Speed limits: 5 knots in brash ice conditions

43.2. Icebreaking Services

– Request deadline: 48 hours notice required

– Priority system: Based on vessel ice class

– Convoys: Maximum 3 vessels per breaker

44. Port Waste Reception

44.1. Handling Facilities

– Oily waste: 500m³ daily processing capacity

– Garbage separation: 7-category system

– Hazardous waste: Secure storage with 24/7 monitoring

44.2. Discharge Procedures

– Advance notice: 24 hours for special wastes

– Documentation: Waste manifests in triplicate

– Fees: Based on MARPOL categories

45. Emergency Response Coordination

45.1. Command Structure

– On-scene commander: Port Director or deputy

– Joint operations: Integrated with local fire and police

– Communication: Dedicated UHF network

45.2. Resource Deployment

– Oil spill: 2000m boom within 2 hours

– Firefighting: 4 foam trucks simultaneous operation

– Medical: Mobile decontamination unit

46. Port Meteorological Services

46.1. Weather Monitoring

– Real-time sensors: Wind speed/direction updated every 5 minutes

– Storm warnings: Issued when sustained winds exceed 25 knots

– Visibility reports: Updated hourly via VHF Ch 14

46.2. Tide and Current Data

– Tide tables: Published annually with 10cm accuracy

– Current meters: Ultrasonic sensors at channel entrance

– Storm surge alerts: 3-hour advance notification

47. Bunkering Operations

47.1. Fuel Quality Standards

– ISO 8217 compliance: Mandatory for all suppliers

– Sampling protocol: Triple-seal samples retained 90 days

– Low sulfur verification: Continuous monitoring during transfer

47.2. Safety Procedures

– Fire zones: 30m radius during bunkering

– Spill containment: Double-hose systems with drip trays

– Communication: Dedicated UHF channel for operations

48. Port Dues and Charges

48.1. Fee Structure

– Vessel size categories: Calculated per GT brackets

– Environmental discount: 15% for Tier III engines

– Overtime premiums: 200% for holiday operations

48.2. Payment Methods

– Electronic transfer: SWIFT/JPY only for international

– Guarantees: Bank guarantees accepted >¥10M

– Disputes: Must be filed within 14 calendar days

49. Ship Chandler Services

49.1. Approved Suppliers

– Certification: ISO 28000:2022 security compliance

– Delivery windows: 0600-1800 only at berth

– Contraband screening: 100% x-ray inspection

49.2. Provisioning Standards

– Food safety: HACCP-certified suppliers only

– Cold chain: Temperature-logged transports

– Waste packaging: Returnable containers mandatory

50. Port Infrastructure Specifications

50.1. Berth Characteristics

– Load capacity: 10t/m² uniform deck loading

– Bollard strength: 150t tested capacity

– Depth tolerances: ±0.5m of charted depths

50.2. Utility Connections

– Shore power: 6.6kV/60Hz standard

– Potable water: 100m³/hr flow rate

– Fire mains: 8 bar pressure at all hydrants

51. Port Wildlife Protection

51.1. Marine Species Conservation

– Restricted zones: Seasonal closures for migratory birds (Oct-Mar)

– Speed limits: 5 knots in manatee habitats

– Lighting controls: Turtle-friendly wavelengths during nesting

51.2. Ballast Water Management

– Exchange requirements: Minimum 200nm offshore

– Treatment systems: IMO Type Approved only

– Sampling: Mandatory for high-risk origins

52. Port Cybersecurity Measures

52.1. Network Protection

– Firewalls: Next-gen with intrusion prevention

– Access controls: Multi-factor authentication

– Encryption: TLS 1.3 for all data transfers

52.2. Operational Technology

– SCADA isolation: Air-gapped critical systems

– Patch management: Weekly security updates

– Incident response: 30-minute SLA for breaches

53. Dangerous Cargo Documentation

53.1. Required Certificates

– IMDG declaration: Shipper-signed original

– Emergency instructions: Vessel-specific plans

– Compatibility matrix: Cargo segregation chart

53.2. Special Permits

– Explosives: Ministry of Transport approval

– Radioactive: Dual agency authorization

– Toxic gases: Certified containment systems

54. Port Community System

54.1. Digital Integration

– Single window: 57 data elements standardized

– API connections: RESTful services for EDI

– Blockchain: For bill of lading verification

54.2. User Requirements

– Authentication: PKI digital certificates

– Data validation: Automated schema checks

– Audit trail: Immutable transaction records

55. Vessel Inspection Regime

55.1. Port State Control

– Targeting matrix: 20 risk factors analyzed

– Deficiency codes: 87 inspection items

– Appeal process: 48-hour objection window

55.2. Class Surveys

– Recognized organizations: 12 approved bodies

– Electronic reports: XML format required

– Validity: 3-month grace period