Commissioning a new vessel allows operators to expand their fleet and increase profitability with additional resources but thedesign of a shiphas a major impact on its subsequent performance and revenue-making capabilities. Withincreasing environmental regulations,such as the Energy Efficiency Design Index (EEDI), new-build ships must be designed with their environmental impact in mind.

What is the Energy Efficiency Design Index?

First introduced alongsideShip Energy Efficiency Management Plans (SEEMPs)in 2011, the EEDI regulations require new-build vessels to achieve a ‘minimum energy efficiency level per capacity mile’ (Resolution MEPC 203 (62), MARPOL Annex VI).

The EEDI measures design efficiency, as opposed to operational efficiency, and is the most important technical measure for new-build vessels (IMO). To comply with the EEDI, a ship must meet the requisite standard for its type and size, expressed in grams of CO2 per capacity mile (sometimes referred to as ‘transport work’ or ‘tonne mile’.).

Therefore, each ship has a:

Providing a ship’s Attained EEDI isequal to or better thanits Required EEDI, it will be deemed compliant with the Energy Efficiency Design Index.

A complex formula is used to calculate a ship’s Required EEDI and Attained EEDI but, in simple terms, it can be expressed as follows:

How Are EEDI Regulations Implemented?

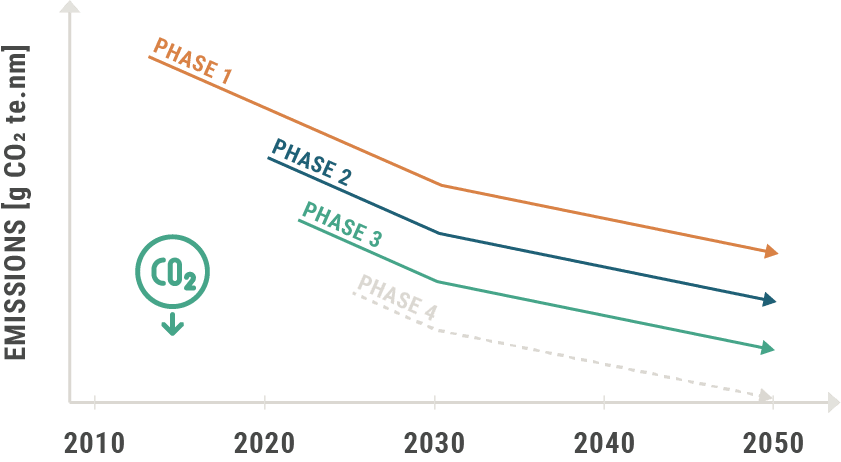

The EEDI increases the energy efficiency of the industry by settingrequired technical efficiency standardsfor new vessels based on an established reference line (baseline). Historical emissions data has been used to set this baseline and, according to EEDI regulations, new vessels must achieve a reduction in terms of percentage.

EEDI: In Practice

For example, gas carriers above 15,000 DWT were required to reduce CO2 emissions by 10% compared to the relevant segment baseline under phase 1 of the EEDI. When phase 2 of the EEDI was introduced, the requisite reduction percentage was 20% and now, under phase 3, gas carriers above 15,000 DWT must reduce CO2 emissions by 30% in comparison with the relevant baseline.

Although the EEDI has been in force for some time, itsrequirements have been strengthened incrementallywith new phases being introduced every few years. With more vessels now subject to the Energy Efficiency Design Index and ships facing lower emissions output standards, it’s more important than ever for shipowners, shipyards and design houses to use thelatest maritime technologyto increase energy efficiency and reduce CO2 emissions.

Phase 3 of the EEDI Brought Forward to April 2022

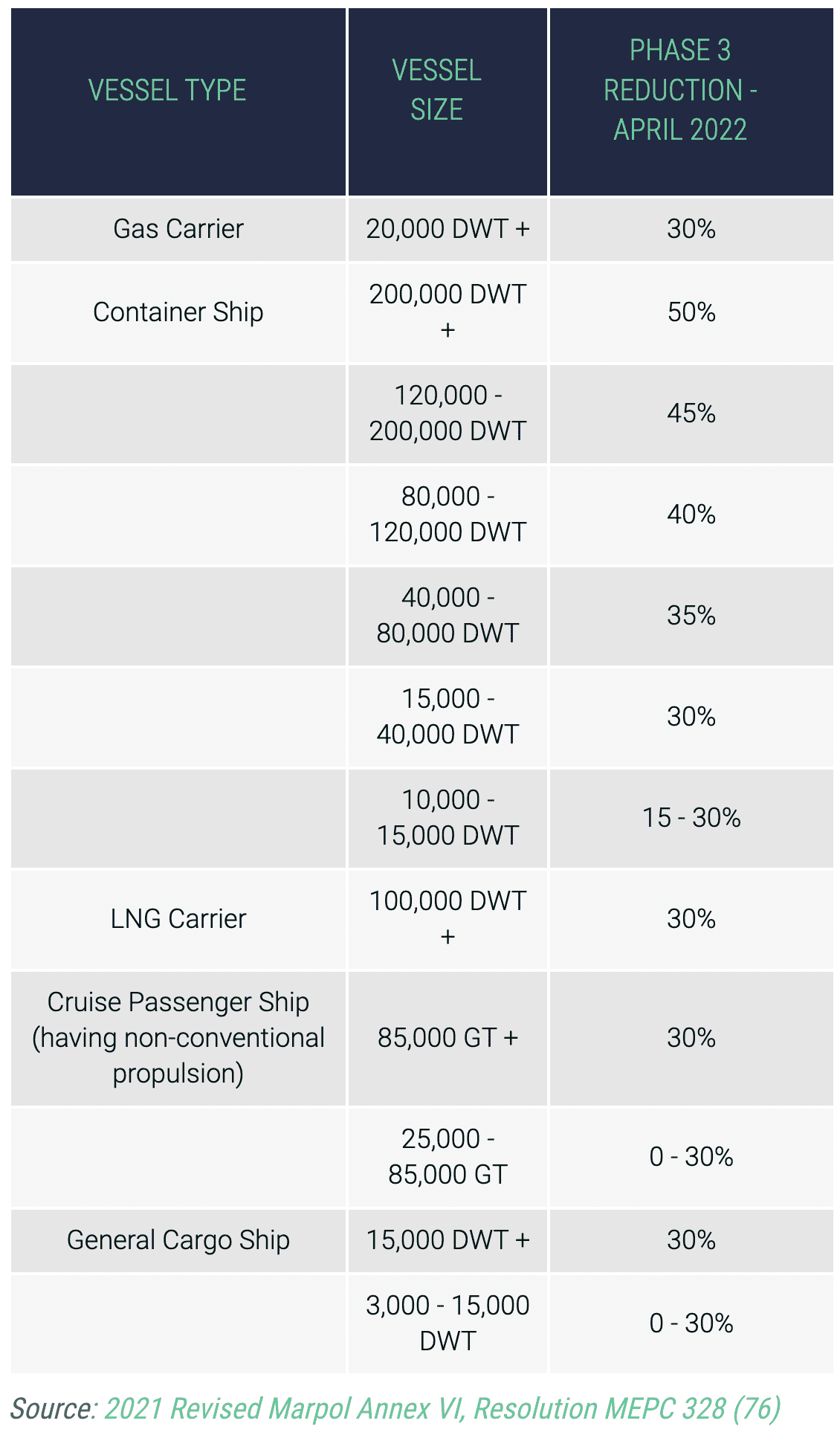

Originally, phase 3 of the EEDI was scheduled to come into force in 2025. In a bid toaccelerate the decarbonization of the shipping industry,however, the IMO brought the implementation of Phase 3 forward to April 2022 and strengthened the regulations even further ((Resolution MEPC 324 (75);2021 Revised Marpol Annex VI, Resolution MEPC 328 (76)).

Following the latest resolution, many vessels will need to meetenhanced emissions reductions.While there are various exclusions which may apply to specific vessels, the regulations broadly require the following reductions:

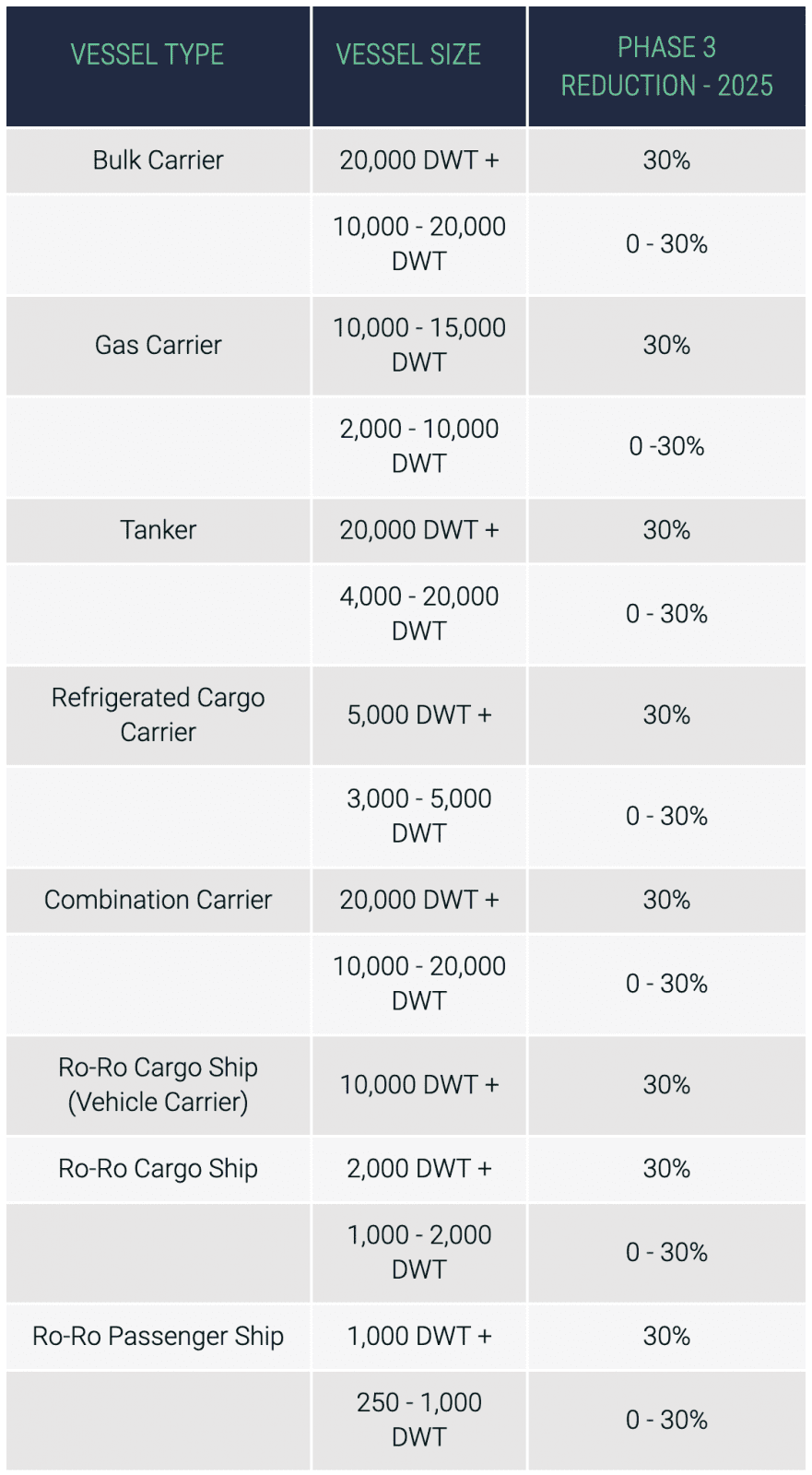

However, these aren’t the only types of vessels that will face increasingly stringent EEDI requirements. Set to come into force in 2025, asecond iteration of Phase 3demands the following reductions

Meeting EEDI Requirements

As environmental regulations tighten across the board, it’s vital that shipowners use thelatest innovationsto achieve the requisite EEDI rating for their vessels. To date, various methods have been used to optimize vessel energy efficiency and, therefore, improve EEDI ratings, including:

As you can see, there are many ways to increase a ship’s energy efficiency and shipowners have been forced to steadily embrace more sustainable shipping methods in order to achieve EEDI compliance thus far. However, theacceleration of Phase 3and the drive towards the decarbonization of the shipping industry (Economist Impact, 2021) means that additional solutions will need to be implemented.

As the EEDI is concerned with the energy efficiency of a ship’s technical design, rather than its operation (which is assessed via other measures, such as the Energy Efficiency Operational Indicator (EEOI) and Carbon Intensity Indicator (CII), it follows thattechnical efficiency can be improved by using onboard technologies.

Ship wire model 3D illustration.

Furthermore, integrating new technologies intonew-build shipscan actually be far easier than retrofitting them onto existing vessels, which gives shipowners striving to achieve optimal EEDI ratings an advantage over those who are battling to achieverequisite EEXI ratings.

However, selecting therightonboard technologies is critical to improving energy efficiency, maintaining crew and passenger safety and achieving optimal vessel performance.

Waste Heat Recovery for EEDI Compliance

Although shipowners are using new forms of tech to improve the energy efficiency of new-build vessels, there is one type of technology that is often overlooked:waste heat recovery (WHR).Despite this, marine WHR can be used to successfully increase energy efficiency and, therefore, enable shipowners, shipyards and design houses to achieve Required EEDI ratings.

What Is Marine Waste Heat Recovery?

Marine waste heat recovery essentially means that onboard waste heat iscaptured, repurposed and used to generate clean, carbon-free electricity.This power is then used by the ship’s grid, which means it is less reliant on diesel-powered generators. As a result,less fuel is used and fewer CO2 emissions are released,which helps to enhance the EEDI rating of the vessel.