Regulations for Permanent Means of Access (PMA) have been in force for more than 15 years. PMA regulations include requirements on the provision andplacement of permanent structures to allow safe access to all compartments of

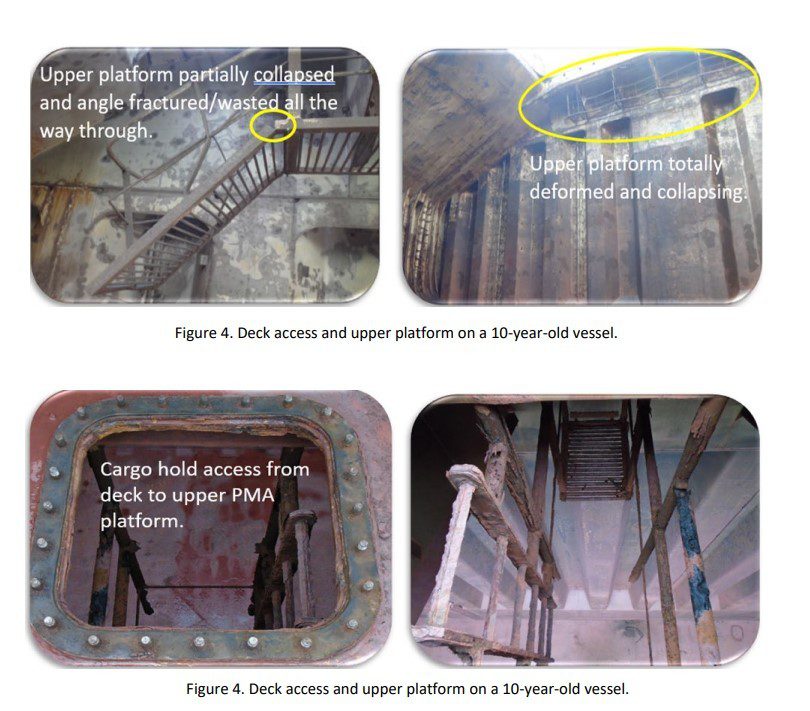

the ship. Just like the ship structure itself, these access structures are susceptible to damage and corrosion. Inspection and maintenance of these PMA structures should be considered when developing a vessel’s Safety Management System.

BACKGROUND & GENERAL REQUIREMENTS:

The maritime industry has long recognized that periodic surveys and inspections are the primary means for verifying that a vessel’s structure is maintained within acceptable standards throughout its operational life. For surveys and inspections to be carried out effectively, suitable means of access to the vessel’s structure are required. In 2002, the IMO adopted a new SOLAS /Regulation 3-6 requiring that new Oil Tankers and Bulk Carriers be provided with a Ship Structure Access Manual, and that their designs take into account the need for regular inspections within hull spaces by provision of installed permanent means of access (PMA), which may be supplemented by alternative means of access (AMA).

Oil Tankers of 500 GT and above, and Bulk Carriers of 20,000 GT and above, constructed on or after January 1, 2006, are required to be fitted with PMA complying with the above noted SOLAS regulation and supporting technical provisions.

Regarding cargo oil tanks, the PMA regulated under SOLAS regulation /3-6 is understood to be those provided for accessing integral cargo oil tanks, and independent cargo oil tanks may be excluded. This regulation is also applicable to FPSOs or FSOs if they are subject to the scope of an enhanced program of inspections as contained in the ESP Code, as amended.

KEY NOTES

• Safety and Cause for Concern

• Applicable Vessel Types:

– Oil Tanker ≥ 500 GT

– Bulk Carriers ≥ 20,000 GT

ABS REGULATORY NEWS /2022

SAFETY AND CAUSE FOR CONCERN

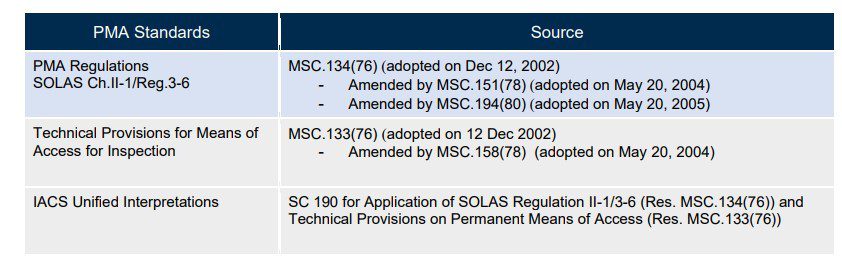

In May 2022, ABS attended a 10-year-old Bulk Carrier in drydock for the progression of Special Survey Hull # 2. The attending Surveyor, with the vessel’s Chief Officer, entered the # 6 Top Side Wing Water Ballast Tank from the main deck access opening and descended onto the upper PMA platform. Shortly thereafter, an entire section of the platform collapsed underneath the Surveyor and Chief Officer (Figure 1). Fortunately, no serious injuries were sustained as both persons held on tightly to the handrails and were able to make their way safely back to the access ladder and leave the tank.

INVESTIGATION OF CARGO HOLD PMA UPPER PLATFORMS

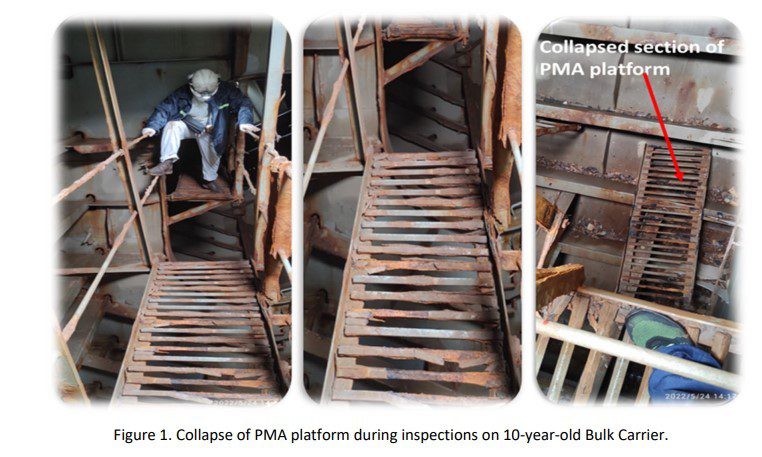

After this “near miss” safety incident, ABS undertook an investigation into the PMA on a number of Bulk Carriers of varying ages (5, 10 and 15 years of age). The investigation identified enough findings to cause concern. The investigation focused solely on the PMA within Bulk Carrier cargo holds and SW Ballast Tanks. The following Figures 2 through 5 depict the various conditions observed.

In recognizing the serious wastage, corrosion and deformation in cargo hold upper PMA platforms as shown in the above figures, ABS investigated further into the regulatory requirements of PMA with respect to maintenance and inspection.

Access to and within spaces in, and forward of, the cargo area of oil tankers and bulk carriers

2.3 … The means of access shall be subject to survey prior to, or in conjunction with, its use in carrying out surveys in accordance

with regulation I/10.

4 Ship structure access manual

4.1 A ship’s means of access to carry out overall and close-up inspections and thickness measurements shall be described in a

Ship structure access manual approved by the Administration, an updated copy of which shall be kept on board. The Ship

structure access manual shall include the following for each space:

4.4 instructions for inspecting and maintaining the structural strength of all means of access and means of attachment, taking

into account any corrosive atmosphere that may be within the space.

4.8 records of periodical inspections and maintenance of the ship’s means of access.

SHIP STRUCTURE ACCESS MANUAL

From the vessels that were inspected, and where the PMAs, and particularly the cargo hold upper platforms, were found in seriously poor condition, the ‘Structure Access Manual’ (SAM) for these vessels was reviewed and the section of the SAM that contained the ‘Records of Inspection and Maintenance’ was devoid of any records, and further no records were attached to the manual.

In reviewing the respective vessels Planned Maintenance System (PMS), there was evidence that cargo holds and tanks were subject to periodic inspection by the vessels crews, but there was no reference to the PMA upper platforms. A further review of the respective vessel’s Safety Management System (SMS) indicated that there were no documented procedures for PMA inspection and maintenance, or retention of records.

APPROACH TO OWNERS

Several owners were contacted and the issue of their vessels’ PMA was discussed, with emphasis on procedures contained in the onboard SMS. From the feedback received, it became apparent that the owners were not fully aware of the statutory regulations with respect to PMS and the requirements in the ‘Structure Access Manual’, as well as what is stated in SOLAS Reg /3-6 and IACS Rec. No.90.

It was further highlighted that during an ISM Audit, and specifically related to Section 10 (Maintenance), that the SMS can be improved by referencing the PMA, and Records of Inspection and Maintenance are required to be maintained onboard and made available for review as and when requested.

SUMMARY

At ABS, safety is a core value. Our objective is to promote the safety of the crew and all personnel who may be required to use the cargo hold, cargo tank, ballast tank PMA, for inspection and survey purposes, and that in all spaces the PMA is maintained in a satisfactory condition.

In cargo holds, cargo tanks and ballast tanks, the PMA can be subject to rapid deterioration due to the corrosive environment of bulk cargoes carried, and the external forces from ship motions and sloshing of liquid contained in tanks.

It is of critical importance that safety is not compromised or overlooked. The near miss, as previously detailed, highlights

the dangers of a lack of maintenance and inspection of the PMA.