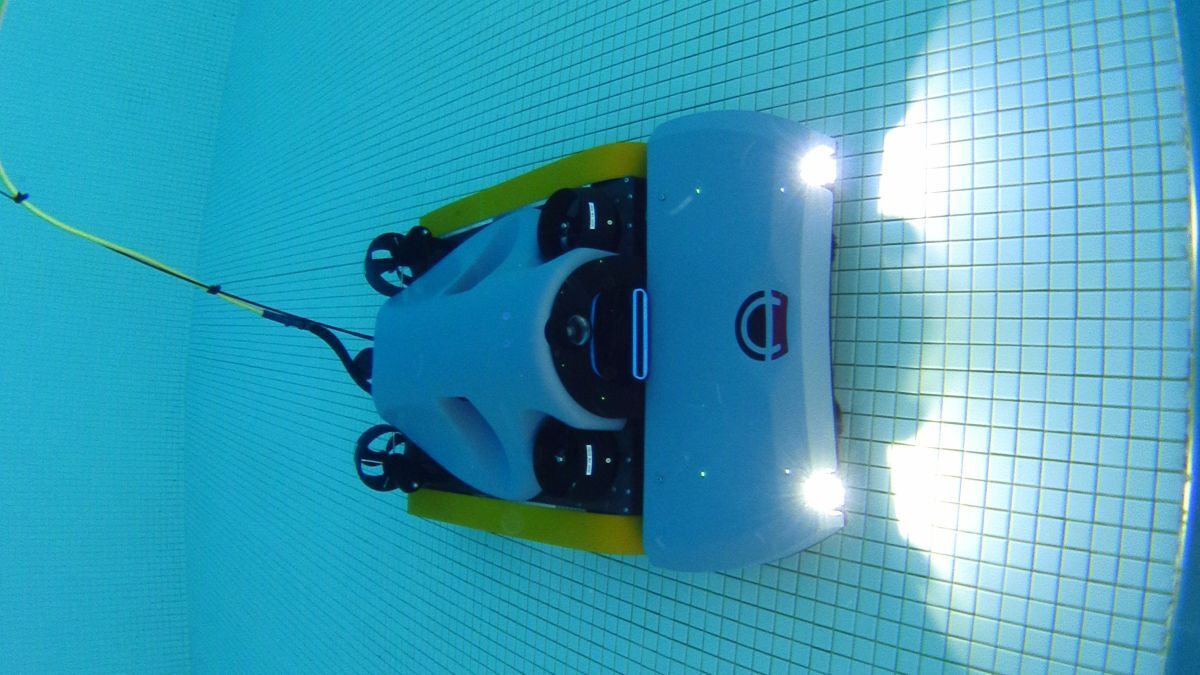

Armach Robotics is testing its autonomous robot by removing hull biofouling on US Navy ships

It has partnered with parent company Greensea Systems, US Naval Research and Maryland’s Maritime Environmental Resource Center (MERC) on this project.

Together, they will develop and trial an autonomous hull-cleaning vehicle under a two-year programme to demonstrate its technical and commercial viability.

This follows earlier development work to design, characterise, develop and test an on-hull navigation system for future robotic units.

Greensea developed a hull-relative positioning system using inertia sensors and sonar to navigate, for use in a hull crawling robot designed and built by Armach Robotics.

This will be capable of determining and continually updating its position on the ship’s hull with extreme accuracy, enabling Greensea’s autonomy capabilities to free the operator from driving the robot. MERC brings its expertise in biofouling control methods and will provide critical support in an independent, scientific assessment of the robots’ navigation, autonomy and cleaning technologies.

Armach Robotics tested its first post-prototype hull service robot, a 30-kg, 86-cm long unit, in underwater trials in Plymouth, Massachusetts on a ship’s hull.

In October, it signed an agreement with Bellona to co-ordinate with the Clean Hull Initiative to raise awareness and understanding among decision-makers in policy and the shipping business of the benefits of proactive hull cleaning.

Accident report: hydrographic survey vessel sinks

An echosounder gantry and shortcomings in construction caused a survey workboat to sink in the UK.

Bella flooded and sank while carrying out hydrographic survey operations in the approaches to Lynmouth, England, 6 July 2021.

According to the UK’s Marine Accident Investigation Branch (MAIB), this accident was caused by multiple issues including the gantry and non-compliance of the vessel.

When the vessel sank, Bella’s crew abandoned into the liferaft and were rescued uninjured by a local boat owner. But the accident could have been prevented.

The MAIB says Bella was vulnerable to swamping, even in moderate sea conditions, “because it’s multibeam echo sounder gantry reduced its forward freeboard.”

Bella was not compliant with The Workboat Code and there were shortcomings in its construction. “And means of flotation were missed during the certifying survey due to the surveyor’s overreliance on Recreational Craft Directive documentation,” says the MAIB.

“Bella’s crew were inexperienced,underestimated the risk of operating the vessel in open seas and were guided by an ineffective safety management system.”

After writing the report, the MAIB recommended the UK’s Maritime Coastguard Agency provide guidance to certifying authorities regarding the application of the Recreational Craft Directive when certifying vessels for commercial operation.

Bella’s owner was advised to implement a safety management system for its vessels that follows the principles of the ISM Code.

Hugin AUVs ordered for naval applications

Kongsberg Maritime has gained a contract award with Polish shipbuilder Remontowa Shipbuilding to supply Hugin autonomous underwater vehicles (AUVs) for three Polish Navy vessels, due to be commissioned 2026-2027.

Hugin AUVswill be used for autonomous, remote subsea search and survey work, witha hydrodynamic design, high battery capacity and accurate instruments for measuring and monitoring.

Installed equipment includes a HISAS 1032 synthetic-aperture sonar for long-range, high-resolution imagery and bathymetry; ultra-high-definition camera and lighting panels for high-resolution optical imagery; forward-looking sonar and altimeters for obstacle avoidance and trajectory planning; low magnetic-signature stinger launch and recovery system and Kongsberg’s Sunstone advanced inertial navigation system.

Sonar display software upgraded

FarSounder has enhanced its SonaSoft sonar software to expand the local history mapping (LHM) application. All models of the Argos forward-looking sonar now can recall user-collected data, only limited by the available hard drive space.

LHM enables users to generate a map of the seafloor as they navigate. FarSounder is adding the ability to view LHM data in its 3D Omni View and chart-view applications on the user interface in Q4 2022.

A single pass of the Argos sonar can map an expansive swath of the seafloor in real time. The LHM application displays this data as a 3D map of the seafloor, which is updated with every ping.

Upon returning to a location where LHM data has been collected, the user will see the bottom history in both views along with the real-time data.

Subsea trenching vehicle delivered

Dredging group Jan De Nul has installed a subsea trenching vehicle on one of its support vessels to assist with cable laying. UK-based Osbit supplied its Swordfish vehicle and cable burial tools. Swordfish is powered by 1,200 kW of subsea electrical power, a combination of direct drive and hydraulic distribution, to provide operators with versatility when applying power to bury cables in the ocean.