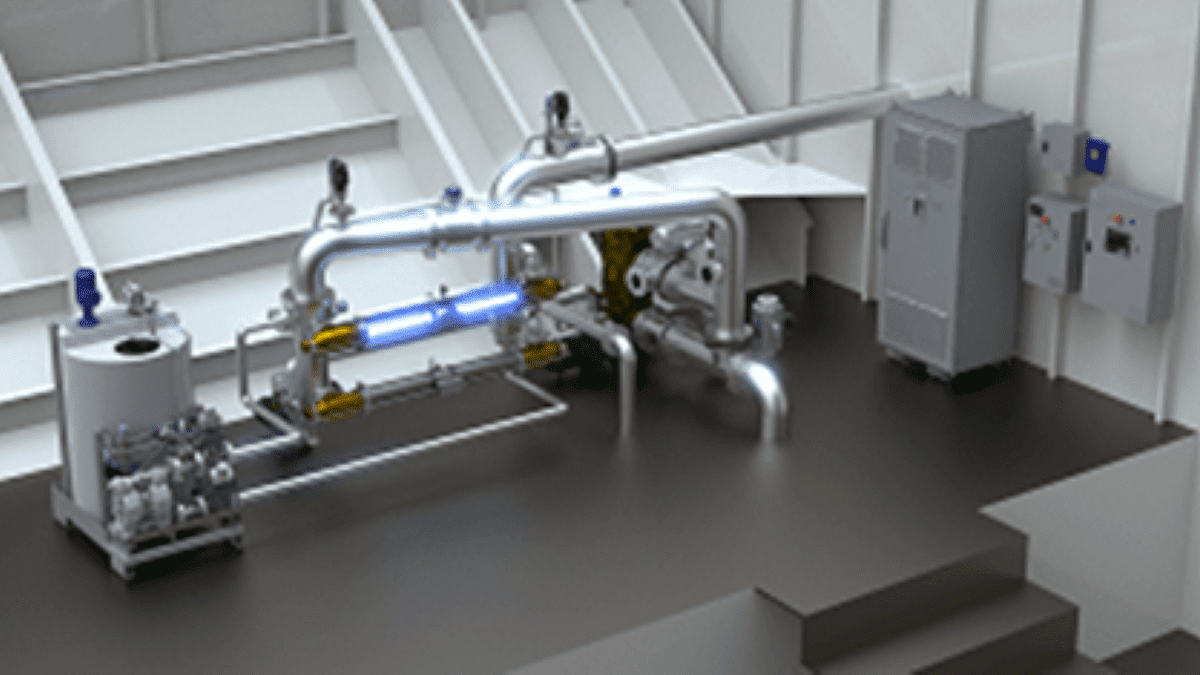

Retrofit installation of BIO-SEA ballast water treatment system in 2002-built ship (source: BIO-SEA)

Retrofit installation of BIO-SEA ballast water treatment system in 2002-built ship (source: BIO-SEA)

The French ballast water management system (BWMS) provider has completed a turnkey retrofit installation of a BWMS system on MSC Caledonia II

2002-built, 1,850-TEU general cargo ship MSC Caledonia II was retrofitted in Port Khalid, Sharjah, UAE, with a BIO-SEA B03-0450 FX modular system prior to the vessel’s sale to Mediterranean Shipping Company (MSC).

The UV water treatment specialist introduced its turnkey BWMS retrofit capability in October last year, with the addition of 3D laser scanning and modelling to its BIO-SEA engineering and design services.

BIO-SEA by BIO-UV Group technical director Florian Cortes said, “This new service was fundamental to the swift completion of this time-sensitive project.”

He added, “The lead time for engineering, system building, and final installation and commissioning was very tight due to the vessel’s schedule. But the pre-installation engineering work we carried out allowed the customer to prefabricate the piping elements, significantly reducing installation and drydock time.”

BIO-SEA by BIO-UV Group business director Maxime Dedeurwaerder said, “This was the first project for our new turnkey service, which included basic and detailed drawings, system design and engineering, installation, commissioning, documentation submissions and crew training.”

As Caledonia was built in 2002, it was inevitably some drawings were missing. The 3D laser scanning, however, provided a complete picture of the available space and helped facilitate a successful and timely installation.

“The customer was able to source all prefabricated piping ahead of the BIO-SEA installation, which is essential to the accuracy of the engineering plan and drawings we supplied. It was a very smooth installation,” said Ms Dedeurwaerder.

The BWMS was successfully commissioned in February, after which the company’s ballast water experts trained the ship’s crew to operate and maintain the system.

Nordic Hamburg Shipmanagement technical superintendent Shahram Khosrowabadi, from the vessel’s former ship management company, said, “BIO-UV Group’s new turnkey BWMS retrofit service helped us reduce installation time, while the 3D modelling helped us find the optimum location for the system.”

A BIO-SEA modular system is specially designed for retrofit projects and can treat flow rates from 13 m3 per hour per ballast pump to 2,100 m3 per hour per ballast pump.

All components are delivered separately to adapt to the available space in the ship.