John T Essberger’s Johan J Isaksen reflected on a century of shipping, digitalisation and navigating a sustainable pathway to net zero

For a family owned company, “what really matters is our people,” said John T Essberger managing director Johan J Isaksen during his acceptance speech for the International Chemical Tanker Industry Leader Award.

Speaking on behalf of the DAL Essberger Group, Mr Isaksen paid tribute to the contribution of the company’s seafarers, describing them as “the backbone of our company” and “the driving force behind our success.”

Reflecting on the company’s 100-year history, Mr Isaksen said, “Last year, we proudly celebrated our 100-year anniversary. Navigating a competitive shipping environment and adapting to shipping cycles and technological disruptions has been essential, not only for our growth but also for our survival.”

He described 2024 as “undoubtedly a landmark year” for the group, with the centennial festivities including two naming ceremonies in Hamburg and signing a newbuilding programme intended to carry the company into its next century.

The award, Mr Isaksen said, recognised the group’s focus on “state-of-the-art newbuildings and strong focus on sustainability.”John T Essberger’s strategy for fleet renewal is firmly aligned with the need for a “meaningful pathway to net zero.”

Mr Isaksen emphasised the group would not place newbuilding orders without clear decarbonisation plans, “There is considerable financial risk to build a ship with a 25-year lifespan,” he said, cautioning without careful planning, vessels could become uncompetitive over time.“Regardless of future fuel availability, achieving the lowest possible consumption makes sense, both today and tomorrow.”

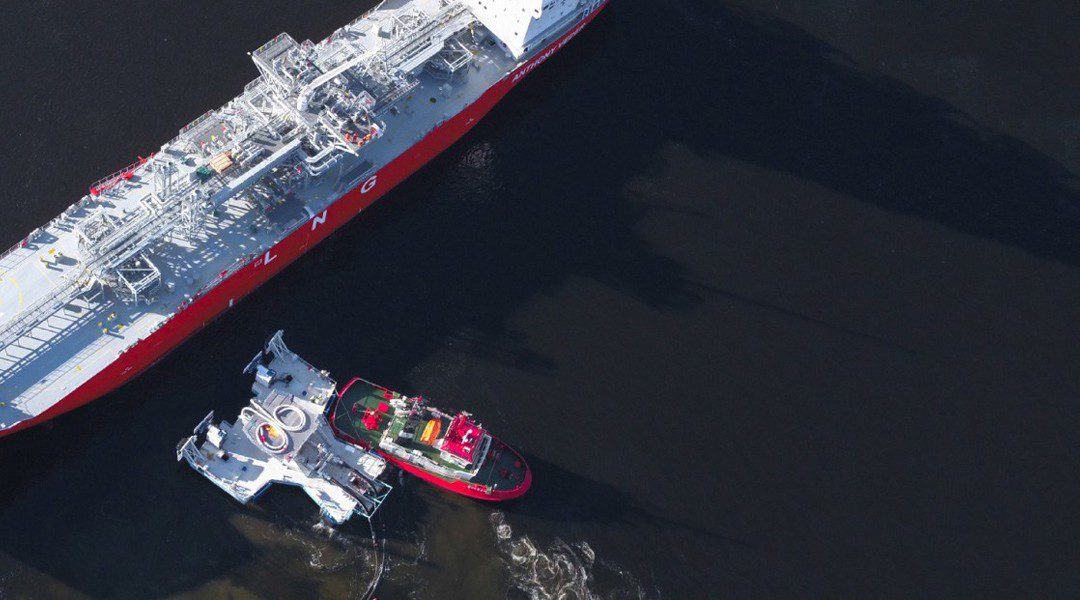

The company’s dual-fuel LNG-powered 7,100-dwt chemical tankers, designed for the northwest European and Baltic trades with Ice Class 1A notations, exemplify this approach.They are equipped with shore power capabilities, despite shoreside infrastructure remaining largely incomplete.

Recent trials with bioLNG, sourced entirely from renewable production, also reflect a proactive stance towards FuelEU Maritime compliance, albeit at “a high extra cost.”

Alongside hardware innovation, digitalisation has been embedded across operations. “Data capture and live performance monitoring enhance our operational decisionmaking as well as our performance,” said Mr Isaksen.“It is great to see we are now able to tap more value from these tools.”

He outlined measures already being implemented, such as hull maintenance strategies, antifouling improvements, and propeller efficiency enhancements, to drive down fuel consumption and emissions.

Looking to the future, Mr Isaksen confirmed new vessels would be methanol-ready, with main engines already approved for conversion and methanol storage solutions installed from delivery.

“If or when greener versions of methanol become available,” he said, minimal modifications would be needed, ensuring the ships remain adaptable.

Concluding his remarks, Mr Isaksen returned to the human element that, he insisted, underpins the company’s success.He praised the seafarers’ resilience, professionalism and commitment, noting, “Their dedication and the challenges they overcome must never be underestimated. Their steadfast commitment propels us forward into the future.”