Recently, the first-phase project of the Xinjiwan Operation Area in the Xingang Port Area of Zhaoqing Port (hereinafter referred to as the “Xinjiwan Wharf Project”), invested and constructed by the Zhaoqing Transportation Group of Guangdong Province, is intensively carrying out final completion and debugging work, striving with full force towards the project completion goal. As a modern port project prioritized by Zhaoqing City, the Xinjiwan Wharf Project has taken initial shape and is planned to commence trial operation by the end of this year.

Core Works Largely Completed

Currently, multiple core components of the Xinjiwan Wharf Project have been completed. The paving of the road and yard surfaces, the construction of the approach bridge, the installation of lifting equipment, as well as the main buildings including the comprehensive office building, canteen, and dormitory buildings have all been finished. The main wharf structure is 93% complete, and the project has overall entered the final stages involving ancillary facilities and comprehensive pipeline networks.

The project construction demonstrates two prominent features. First, Party building guidance is deeply integrated into the frontline work; second, the green and low-carbon concept runs throughout the entire process. By integrating the application of photovoltaic power generation, energy storage systems, and a smart energy management platform, the project is expected to have a new energy electricity proportion exceeding 50% after operation, with plans to increase this to over 90% in the long term, aiming to create a model “near-zero carbon” inland river wharf.

Seizing the Golden Construction Period, Ample Resource Guarantees

With the end of the rainy season in the Zhaoqing area, the project is seizing the golden window period for construction. According to the project leader from the Zhaoqing Port Company, efforts will be intensified in three aspects to advance the project: First, optimizing the construction plan, focusing on key processes such as ancillary facilities, comprehensive pipeline networks, and the wharf frame structure, detailing milestones, assigning responsibilities, and strictly implementing the “daily scheduling, weekly assessment” mechanism; Second, strengthening resource guarantees, with 85 construction personnel currently on site and 10 pieces of mechanical equipment such as truck cranes and pump trucks deployed to ensure seamless workflow transitions; Third, strictly adhering to safety bottom lines, implementing daily pre-shift safety briefings, and focusing on identifying risks such as work at height and special equipment operation to safeguard the smooth progress of the project.

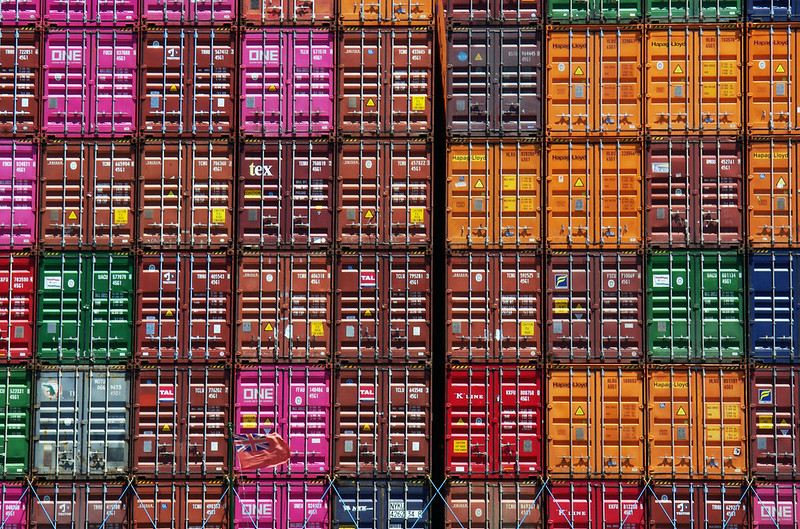

The Xinjiwan Wharf Project has a total investment of 721 million yuan, with a designed annual throughput capacity of 3.1 million tons (including 100,000 TEUs of containers). It is equipped with three 3000-ton-class multi-purpose berths (designed with a hydraulic structure for 5000-ton-class vessels) and can handle bulk cargo, general cargo, and container operations. Upon completion, the project will significantly enhance the capacity grade of Zhaoqing’s inland river ports and further optimize the regional logistics system.