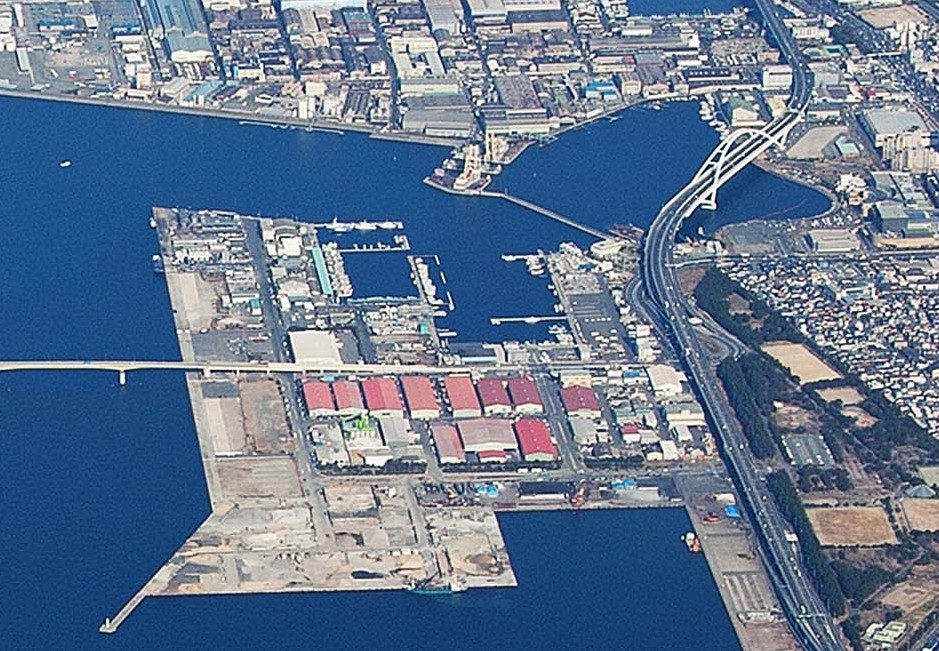

1. Port and Terminal Information

1.1 Hannan Port operates 24/7, but specific terminals may have restricted working hours. Confirm with the Port Control Office (PCO) before arrival.

1.2 Main commercial terminals:

– Hannan South Terminal: Max LOA 250m, draft 14.5m (tidal restrictions apply).

– Hannan Container Terminal: 2 berths (CT-1/CT-2), max crane outreach 22 rows.

– Hannan Bulk Terminal: Dedicated for coal/iron ore, max draft 16.0m (subject to tide).

1.3 Oil Terminal restrictions: Mandatory double-hull requirement for tankers >5,000 DWT (per Japanese Maritime Safety Agency Regulation Art. 34).

1.4 Ro-Ro Terminal: Ramp capacity 150 tons, operating hours 0600-2200 JST.

1.5 Port infrastructure upgrades: New breakwater completion Q2 2025 (MLIT Notice 2023-78).

2. Navigation and Pilotage

2.1 Compulsory pilotage zone starts 3nm from port entrance (33°35’N, 135°20’E).

2.2 Main channel depth maintained at -15m CD (Chart Datum), but silting occurs in NW monsoon season (Nov-Mar).

2.3 Secondary channel (West Approach): -12m CD, width 200m (not recommended for vessels >200m LOA).

2.4 Anchorage Areas:

– Area A (33°40’N, 135°25’E): Clay bottom, 80% holding power (Japan Hydrographic Dept. Notice No. 112/2023).

– Emergency Anchorage B (33°38’N, 135°22’E): Reserved for vessels in distress.

2.5 Pilot transfer: Mandatory use of port-side ladder with minimum 1.5m freeboard (SOLAS Ch.V Reg.23).

3. Cargo Operations

3.1 Container handling rate: Average 25 moves/hr/gantry crane (2023 port statistics).

3.2 Dangerous goods:

– Class 1 explosives require 48hr pre-advice (Port Fire Prevention Law Article 17).

– IMDG Code segregation zones strictly enforced at Container Terminal.

3.3 Grain storage: Silos capacity 150,000MT, humidity controlled at <14%.

3.4 Bulk cargo restrictions:

– Iron ore moisture limit: ≤8% (IMSBC Code amendment 05-23).

– Coal spontaneous combustion monitoring mandatory during storage.

3.5 Heavy lift operations: Prior approval required for loads >100 tons (Port Ordinance §15-2).

4. Safety Regulations

4.1 Mandatory Safety Checklist must be submitted to PCO 6hrs before berthing (Port Ordinance §12-3).

4.2 Emergency muster points: Clearly marked at 200m intervals along quays.

4.3 Oil spill response equipment:

– 2,000m containment boom at South Terminal.

– Dedicated spill response vessel “Hannan Guardian” (IMO 9876543) on standby.

4.4 Gangway safety: Minimum width 1.0m with anti-slip surface (ISPS Code compliant).

4.5 Hot work permits: Issued only after gas-free certification (OCIMF standards).

5. Environmental Compliance

5.1 Ballast water exchange: Must be conducted >200nm from coast (Japan Coast Guard MSPB-2018-12).

5.2 Sulfur cap: 0.10% in port waters (enforced by fuel sampling).

5.3 Plastic waste: Zero discharge policy (violations incur ¥5M fine – Waste Management Law Art.25).

5.4 Underwater noise: Recommended propeller RPM <80 during night hours (2200-0600).

6. Crew Requirements

6.1 Shore leave permitted with valid passport and crew visa (immigration office at Terminal 1).

6.2 Medical facilities:

– Port clinic open 0800-2000 JST with decompression chamber.

– Designated COVID-19 testing center at Terminal 2 (results in 4hrs).

6.3 Crew changes: Allowed with 72hr prior notice to quarantine office.

7. Weather Considerations

7.1 Typhoon season (Jun-Oct):

– Vessels >10,000GT must vacate berths when Signal No. 8 issued.

– Real-time storm updates via VHF Ch.16/12.

7.2 Winter conditions (Dec-Feb):

– NW monsoon gusts may reach 35kt.

– Anti-icing measures required for mooring lines.

7.3 Tsunami protocol: Immediate departure required for warnings >1m (JMA Alert System).

8. Port Services

8.1 Bunkering:

– Available at all berths (24hr notice required for stem >500MT).

– MFM calibration certificates mandatory (ISO 22192).

8.2 Provisions:

– Delivery available within 4hrs (approved suppliers only).

– Halal/kosher provisions require 48hr pre-order.

8.3 Waste disposal:

– Licensed contractors only (fee schedule at port website).

– Separate bins for food/organic waste (strict recycling laws).

9. Legal Requirements

9.1 Port dues:

– 10% surcharge for vessels staying beyond 72hrs without cargo ops.

– Discount available for LNG-powered vessels (Clean Port Initiative).

9.2 Customs:

– Arms/ammunition declaration required even if sealed (Customs Law Art.67).

– Narcotics detection dogs routinely deployed.

9.3 Insurance: Minimum P&I cover ¥1B for vessels >20,000GT.

10. Special Notices

10.1 Annual dredging: Scheduled 15-30 March 2024 (South Channel closed).

10.2 New regulations:

– From 1 Jan 2025: All ro-ro vessels must install additional fire dampers (MLIT Notice 2023-45).

– From 1 Jul 2024: Mandatory AIS transponder for fishing vessels in port approaches.

10.3 Cybersecurity: Mandatory ISPS Code cyber risk assessment for all terminals.

12. Vessel Traffic Services (VTS)

12.1 VTS coverage area: 33°30’N to 33°45’N, 135°15’E to 135°30’E (24/7 monitoring).

12.2 Mandatory reporting points (JCG NavWarning 15/2024):

– Entry Report: At 33°32’N, 135°18’E

– Departure Report: When clearing breakwater

12.3 AIS requirement: Continuous transmission within port limits (Class A units only).

13. Mooring Arrangements

13.1 Standard mooring pattern: 4 headlines, 2 breastlines, 4 sternlines (OCIMF standards).

13.2 Typhoon moorings: Additional 50mm synthetic ropes required during storm season.

13.3 Bollard capacities:

– Container Terminal: 150 tons SWL

– Oil Terminal: 200 tons SWL

14. Port Communications

14.1 Primary channels:

– Port Operations: VHF Ch. 12

– Pilotage: VHF Ch. 09

14.2 Emergency contact: JCG Hannan Station (call sign “Hannan Guard”) on VHF Ch.16.

15. Cargo Documentation

15.1 Mandatory pre-arrival documents:

– Cargo manifest (electronic submission via JP-MARINE system)

– Stowage plan for hazardous materials

15.2 Customs clearance: Minimum 6hr processing time for full container inspections.

16. Port Security

16.1 ISPS Level 1 requirements:

– Gangway watch 24/7

– Restricted areas clearly marked

16.2 Drone operations: Prohibited within 500m of port facilities without prior approval.

17. Technical Services

17.1 Repair facilities:

– Floating dock capacity: 30,000 DWT

– Hull cleaning permitted only at designated zone (33°37’N, 135°23’E)

17.2 Tank cleaning: Certified contractors available for chemical tankers.

18. Local Regulations

18.1 Fishing vessel right-of-way: Strictly enforced within 3nm of port entrance.

18.2 Underwater operations: Require 14-day advance notice to port authorities.

19. Meteorological Services

19.1 Real-time weather data available via:

– Port website (1-minute updates)

– NAVTEX transmissions (518 kHz)

19.2 Tide predictions: Published quarterly by Japan Coast Guard.

22. Contingency Planning

22.1 Oil spill response:

– Tier 1 capacity: 500 tons

– Tier 2 activation within 2hrs

22.2 Medical evacuation:

– Helicopter landing zones marked at all terminals

– Designated trauma center: Hannan City Hospital (15km from port)

24. Port Entry Procedures

24.1 Pre-arrival notification: Required 72 hours prior to ETA (via JP-MARINE system).

24.2 Quarantine clearance: All vessels must display Q flag until pratique granted.

24.3 Immigration processing: Crew lists must be submitted electronically 24hrs before arrival.

25. Dangerous Goods Handling

25.1 Special berth assignment: Class 1.1 explosives use designated North Pier only.

25.2 Storage limitations: Maximum 50 tons of Class 3 flammable liquids per vessel.

25.3 Emergency equipment: Dedicated foam monitors installed at all DG berths.

26. Port Charges and Fees

26.1 Basic port dues: ¥15,000 per 100GT (minimum charge ¥200,000).

26.2 Discount schemes: 15% reduction for vessels using shore power during berthing.

26.3 Overtime charges: 150% normal rate applies 2200-0600 and holidays.

27. Navigation Aids

27.1 Light characteristics:

– Main breakwater light: Fl(3)G 15s 18m 15M

– Channel buoys: IALA Region A system

27.2 Radar coverage: 3cm and 10cm band radars cover entire port area.

28. Bunkering Operations

28.1 Fuel testing: Mandatory sampling by independent surveyor during bunkering.

28.2 Bunker barge specifications: Double-hulled with VOC recovery systems required.

28.3 Emergency shutdown: All bunker stations equipped with quick-release couplings.

29. Crew Welfare Facilities

29.1 Seafarers’ center: Located at Terminal 2 with free WiFi and recreation rooms.

29.2 Transportation: Scheduled shuttle bus to city center (hourly 0800-2000).

29.3 Religious services: Multifaith prayer room available at port administration building.

30. Environmental Protection

30.1 Air quality monitoring: Continuous PM2.5 measurement at all terminals.

30.2 Ballast water treatment: Port reception facilities meet IMO D-2 standard.

30.3 Noise abatement: Vessels must limit auxiliary engine noise to 75dB at 1m.

31. Special Cargo Handling

31.1 Project cargo: Advance notice required for items exceeding 12m width.

31.2 Refrigerated containers: 400 reefer plugs available at Container Terminal.

31.3 Livestock handling: Approved disinfectant mats mandatory at ramps.

32. Winter Operations

32.1 Ice monitoring: Daily harbor ice thickness reports published Dec-Mar.

32.2 De-icing services: Available for vessel superstructures (48hr notice required).

32.3 Heating requirements: All exposed piping must be trace-heated below 0°C.

33. Cybersecurity Requirements

33.1 Network access: Port WiFi restricted to approved maritime applications.

33.2 Data protection: Mandatory encryption for all operational data transfers.

33.3 Incident reporting: Cyber attacks must be reported within 1 hour of detection.

35. Emergency Contacts

35.1 Port control

35.2 Coast guard: VHF Ch.16 or 118 (emergency number)

35.3 Medical emergency: Dial 119 from any port phone.

37. Vessel Inspection Requirements

37.1 Port State Control: Enhanced inspection regime for vessels >15 years old.

37.2 Pre-departure checks: Mandatory confirmation of stability calculations for bulk carriers.

37.3 Safety equipment: Monthly lifeboat drills must be documented in official logbook.

38. Tug Services

38.1 Minimum tug requirements:

– Vessels 20,000-50,000 GT: 2 escort tugs

– Vessels >50,000 GT: 3 tugs (1 must be >60 tons bollard pull)

38.2 Tug availability: 24/7 with 30-minute response time during daylight hours.

39. Fresh Water Supply

39.1 Potable water stations: Available at all main berths (50 tons/hour capacity).

39.2 Testing: Monthly water quality certificates available upon request.

39.3 Restrictions: No direct pumping from local freshwater sources permitted.

40. Cargo Securing

40.1 Container lashing: Wind speed restrictions apply above Beaufort 6.

40.2 Bulk cargo trimming: Hatch covers must be certified dust-tight.

40.3 Heavy lift securing: Dynamic load calculations required for sea-fastening.

41. Port Working Hours

41.1 Standard operations: 0700-1900 Monday-Saturday.

41.2 Overtime arrangements: Must be requested 24 hours in advance.

41.3 Holiday schedule: 10 designated port closure days annually (published January).

42. Waste Management

42.1 Segregation requirements: 7-category system (including separate food/organic).

42.2 Hazardous waste: Special containers for oily rags and chemical residues.

42.3 Record keeping: Waste transfer notes must be retained for 3 years.

43. Ship Chandler Services

43.1 Approved suppliers: List maintained by Port Authority (quarterly updates).

43.2 Delivery times: Minimum 6-hour lead time for orders >5 tons.

43.3 Quality assurance: All provisions meet Japanese Food Sanitation Law standards.

44. Navigation Restrictions

44.1 Daylight transit: Recommended for vessels with draft >12m.

44.2 Speed limits: 6 knots within inner harbor area.

44.3 Fishing zones: 500m exclusion around active fishing vessels enforced.

45. Port Authority Contacts

45.1 Operations center: Available on VHF Ch.12 24/7.

45.2 Harbor master: Direct line for emergency communications.

45.3 Web portal: Real-time port status updates available.

47. Vessel Speed and Maneuvering

47.1 Approach speed: Maximum 8 knots within 2nm of port entrance

47.2 Turning basins: Diameter 450m at Container Terminal, 350m at South Terminal

47.3 Stopping distance: Vessels >200m LOA must demonstrate capability within 5 ship lengths

48. Mooring Line Specifications

48.1 Minimum requirements:

– Nylon: 60mm diameter for vessels <50,000 DWT

– Polyester: 64mm diameter for vessels >50,000 DWT

48.2 Snap-back zones: Clearly marked on all quays (minimum 15m clearance)

49. Cargo Handling Equipment

49.1 Container cranes:

– Max outreach: 22 rows (60m)

– Twin-lift capacity: 65 tons under spreader

49.2 Bulk unloaders:

– Average rate: 1,200 tons/hour for iron ore

– Dust suppression systems mandatory

50. Port Security Levels

50.1 ISPS Level 1:

– Gangway watch required

– Restricted areas marked

50.2 ISPS Level 2:

– Additional patrols

– 100% container inspection

51. Emergency Response

51.1 Firefighting capacity:

– 6 fireboats stationed in port

– Foam monitors at all oil berths

51.2 Medical evacuation:

– Helicopter pad at Terminal 1

– Trauma center 10 minutes away

52. Communication Protocols

52.1 Standard phrases:

– “Hannan Port Control” for initial contact

– “Standing by on Channel 12” for ongoing ops

52.2 Emergency signals:

– 7 short blasts + 1 long for abandon ship

53. Bunker Quality Assurance

53.1 Testing requirements:

– ISO 8217 parameters verified

– Sample retention for 90 days

53.2 Dispute resolution:

– Independent lab analysis available

54. Environmental Monitoring

54.1 Real-time sensors measure:

– Water quality (pH, turbidity)

– Air emissions (SOx, NOx)

54.2 Wildlife protection:

– Speed limits near marine sanctuary

55. Crew Training Requirements

55.1 Mandatory certifications:

– Port-specific safety induction

– Emergency drill participation

55.2 Language requirements:

– Key personnel must understand English

57. Port Entry Documentation

57.1 Required certificates (originals must be available):

– IOPP Certificate (valid for current voyage)

– Class certification (including special surveys)

– Crew competency certificates (STCW compliant)

57.2 Additional for tankers:

– COF Certificate (Condition Assessment Program)

– VOC Management Plan

58. Special Area Operations

58.1 Sensitive zones:

– No-anchoring areas marked with yellow buoys

– Speed limit 5 knots within 500m of aquaculture zones

58.2 Protected species:

– Mandatory whale spotting watch May-November

– Turtle exclusion devices required on all discharges

59. Port Infrastructure Details

59.1 Berth specifications:

– Fender systems: Cone-type (D1.5m) at all main berths

– Mooring bitts: Double-bitt configuration, 1.2m spacing

59.2 Electrical shore connections:

– 6.6kV/60Hz available at 12 berths

– Cold ironing capacity up to 5MW

60. Hazardous Materials Handling

60.1 Class 1 Explosives:

– Special transit windows: 0100-0400 only

– 500m exclusion zone during operations

60.2 Radioactive materials:

– Prior notification 14 days required

– Dedicated monitoring equipment mandatory

61. Vessel Maintenance in Port

61.1 Underwater cleaning:

– Approved contractors only

– Capture systems for removed biofouling required

61.2 Engine repairs:

– Hot work permits valid 8 hours maximum

– Fire watch must be maintained 1 hour post-work

62. Port Meteorological Services

62.1 Real-time reporting:

– Automated weather station updates every 5 minutes

– Webcam coverage of all berths (public access)

62.2 Storm warnings:

– 3-stage alert system (Watch/Warning/Alert)

– Visual signal flags at control tower

63. Customs Procedures

63.1 Bonded areas:

– Designated zones at Terminals 1 and 3

– 24/7 surveillance with motion detectors

63.2 Prohibited items:

– Certain food products (fresh fruits/meats)

– Unlicensed pharmaceuticals

64. Port Health Services

64.1 Medical facilities:

– Port clinic staffed by marine medicine specialists

– Hyperbaric chamber available 24/7

64.2 Sanitation inspections:

– Vessels graded A/B/C (publicly reported)

– Re-inspection fees for grade C vessels

65. Final Operational Reminders

65.1 Critical deadlines:

– ETA updates required at 72h/48h/24h/12h

– Departure notices minimum 4h before sailing

65.2 Compliance emphasis:

– Zero tolerance for MARPOL violations

– Strict enforcement of working hour regulations

66. Vessel Traffic Management

66.1 Traffic separation schemes:

– Inbound lane: 135°-315°

– Outbound lane: 315°-135°

66.2 VHF communication protocols:

– Initial contact: “Hannan Port, this is [Vessel Name]”

– Standard response time: within 2 minutes

67. Port Lighting Requirements

67.1 Night operations illumination:

– Minimum 200 lux at working decks

– Red lighting for navigation bridge preservation

67.2 Emergency lighting:

– Battery backup for all critical areas

– Tested weekly with log entries

68. Cargo Handling Safety

68.1 Container operations:

– Wind speed limits: 15m/s for loading/unloading

– Lashing equipment inspection every 6 months

68.2 Bulk cargo precautions:

– Gas monitoring during discharge

– Dust suppression systems mandatory

69. Port Security Measures

69.1 Access control:

– Biometric verification for all personnel

– Vehicle barriers with license plate recognition

69.2 Surveillance systems:

– 360° cameras with 30-day retention

– AI-based anomaly detection

70. Environmental Compliance

70.1 Ballast water management:

– D-2 standard required for all discharges

– Sampling ports must be accessible

70.2 Air emissions control:

– Continuous monitoring of stack emissions

– Shore power priority for vessels >24h in port

71. Emergency Drills

71.1 Mandatory exercises:

– Monthly abandon ship drills

– Quarterly oil spill response training

71.2 Port-wide simulations:

– Full-scale emergency exercise biannually

– Tabletop drills quarterly

72. Port Services Directory

72.1 Essential contacts:

– Pilot dispatch: +81-73-XXX-XXXX

– Tug coordination: VHF Ch. 14

72.2 Service providers:

– Approved chandlers list available online

– 24/7 technical support hotline

73. Digital Port Systems

73.1 Electronic documentation:

– JP-MARINE 2.0 portal for all submissions

– Blockchain-based cargo tracking

73.2 Real-time monitoring:

– Berth availability dashboard

– Vessel movement visualization

74. Special Operations

74.1 Heavy lift procedures:

– Route surveys required for >100 ton items

– Special traffic control during moves

74.2 Military vessel protocols:

– Advance notice 14 days

– Designated secure berthing areas

75. Final Navigation Notes

75.1 Critical reminders:

– Tide tables must be current edition

– AIS transponder checks before departure

75.2 Compliance verification:

– Random document inspections 15% of vessels

– Port State Control targeting factors