1. Port and Terminal Operations

1.1 Karatsu Port operates 24/7, but specific terminals may have restricted working hours. Confirm with the Karatsu Port Authority (KPA) or terminal operators in advance.

1.2 The main commercial terminals are:

– Karatsu Central Wharf: Max LOA 200m, draft 10.5m, handles general cargo and containers.

– Higashi-Karatsu Wharf: Max LOA 150m, draft 8.0m, primarily for coastal vessels and fisheries.

1.3 All vessels exceeding 3,000 GT must submit a Pre-Arrival Notification (PAN) 72 hours prior to ETA via the Japan Coast Guard’s electronic reporting system.

2. Navigation and Pilotage

2.1 Mandatory pilotage for vessels over 10,000 GT or LOA exceeding 120m. Pilot boarding area at 33°27’N 129°58’E (1.5nm NW of port entrance).

2.2 Main channel depth maintained at 12m (Chart datum), with tidal range up to 3.2m during spring tides. Under-keel clearance must exceed 10% of draft.

2.3 Prohibited anchorage zones exist within 0.5nm of the breakwater. Designated anchorage area at 33°26’N 129°57’E with holding ground of mud/sand.

3. Cargo Handling Regulations

3.1 Hazardous materials handling requires prior approval from KPA and Saga Prefecture authorities. IMDG Code compliance is strictly enforced.

3.2 Grain operations require Fumigation Management Plan submission 48 hours before loading.

3.3 Container weight verification (VGM) must follow SOLAS requirements, with weighbridge available at Central Wharf.

4. Safety and Emergency

4.1 Port Security Level 1 (MARSEC) is normally in effect. Higher levels may be implemented with 12-hour notice.

4.2 Oil spill response equipment is stationed at the port entrance. Immediate reporting required for any spill exceeding 100 liters.

4.3 Emergency contact: Japan Coast Guard Karatsu Office +81-955-72-0110 (official 24/7 contact).

5. Environmental Compliance

5.1 Open-loop scrubber discharge prohibited within port limits per Saga Prefecture Ordinance No. 42 (2019).

5.2 Mandatory use of low-sulfur fuel (≤0.1%) while berthing, in accordance with Japan’s Air Pollution Control Law.

6. Crew and Vessel Requirements

6.1 Gangway must be equipped with safety net and illuminated from sunset to sunrise.

6.2 Garbage disposal available at dedicated reception facilities (Central Wharf). Advance notice required for large quantities.

6.3 Fresh water supply pressure: 3.5kg/cm² at all berths, with prior reservation needed for quantities exceeding 100 tons.

7. Local Regulations

7.1 Fishing gear stowage certificates required for vessels transiting nearby fishing grounds (within 20nm radius).

7.2 Night navigation within port limits restricted to vessels with approved lighting plans.

7.3 All crew shore leave must comply with Japan Immigration procedures. No disembarkation without valid landing permits.

8. Weather Considerations

8.1 NW winds exceeding 15m/s may cause berthing restrictions at exposed wharves from November to March.

8.2 Typhoon contingency plans must be filed with KPA when tropical storms enter 500nm radius.

8.3 Fog signals (3 prolonged blasts) are mandatory when visibility drops below 1nm in the approach channel.

9. Port Services

9.1 Bunker supply available through pre-arranged contracts only (no spot market operations).

9.2 Provisions delivery requires 24-hour advance notice with complete customs documentation.

9.3 No ship repair facilities available. Nearest drydock in Fukuoka (60nm west).

11. Customs and Immigration Procedures

11.1 All vessels must submit crew and passenger manifests electronically via Japan Customs’ NACCS system at least 24 hours before arrival.

11.2 Prohibited items include certain agricultural products and unlicensed medications. Full list available at Saga Customs Office website.

11.3 Immigration clearance is conducted at the berth. No crew changes permitted without prior approval from Nagasaki Immigration Bureau.

12. Port Dues and Charges

12.1 Harbor dues calculated based on GT: ¥35/GT for international vessels, ¥20/GT for domestic (2024 rates).

12.2 Waste disposal fees: ¥5,000 per cubic meter for general garbage, ¥15,000 for hazardous waste.

12.3 Pilotage fees: ¥85,000 for vessels 10,000-30,000 GT, ¥120,000 for >30,000 GT (daytime rates).

13. Vessel Traffic Services (VTS)

13.1 Mandatory VHF Channel 16 monitoring within 12nm of port entrance. Shift to working Channel 12 after initial contact.

13.2 Speed limit: 8 knots within breakwaters, 5 knots when passing fishing boats or small craft.

13.3 VTS operational hours: 0600-2200 JST. Night movements require 4-hour prior notice.

14. Mooring Requirements

14.1 Minimum mooring lines: 4 head lines + 4 stern lines for vessels >150m LOA, all synthetic lines must be ≥50mm diameter.

14.2 Tugs compulsory for berthing/unberthing when wind exceeds 15 knots beam-on.

14.3 Fenders must be properly inflated with pressure logs available for inspection.

15. Cargo Documentation

15.1 Original Bill of Lading required for all containerized cargo releases.

15.2 Dangerous goods manifests must include Japanese translations of UN numbers and proper shipping names.

15.3 Timber cargo certificates must prove fumigation compliance with ISPM 15 standards.

16. Port Security Measures

16.1 ISPS Level 1 procedures enforced. All visitors require photo ID and pre-approved port passes.

16.2 Underwater hull inspections prohibited without 72-hour notice to KPA and Japan Coast Guard.

16.3 Drone operations within 1nm of port facilities require special permission from Saga Prefecture Aviation Bureau.

17. Health and Quarantine

17.1 Maritime Health Declarations must be submitted via Q-flag system before arrival.

17.2 Medical waste disposal requires separate approval from Saga Prefecture Health Department.

17.3 Rat guards must be rigged on all mooring lines during cargo operations.

18. Communication Protocols

18.1 Port Control call sign: “Karatsu Port Radio” on VHF Ch 12/16.

18.2 Emergency distress signals must be repeated via Inmarsat-C to Japan MRCC (MMSI 004310000).

18.3 Agent contact details must be displayed on bridge notice boards throughout port stay.

19. Bunkering Operations

19.1 Double valve isolation required during bunkering. No simultaneous operations with cargo handling.

19.2 Bunker samples must be sealed and signed by both vessel and supplier representatives.

19.3 Maximum transfer rate: 200m³/hour for IFO, 100m³/hour for MGO.

20. Local Navigational Hazards

20.1 Strong tidal currents (up to 3 knots) occur near the western breakwater during ebb tides.

20.2 Fishing nets frequently deployed within 2nm of port entrance between April-October.

20.3 Submarine cable area marked by yellow buoys at 33°25.5’N 129°56.8’E – no anchoring within 500m.

21. Ballast Water Management

21.1 Mandatory ballast water exchange beyond 200nm from shore or treatment per Japan’s BWM Regulations (aligned with IMO D-2 standard).

21.2 Sampling may be conducted by Japan Coast Guard inspectors for invasive species testing.

21.3 Ballast operations within port limits require prior approval from KPA Environmental Division.

22. Ice Navigation (Winter Operations)

22.1 No icebreaking services available. Vessels must confirm hull ice class certification when temperatures drop below 0°C.

22.2 Deck anti-icing measures required for vessels arriving from sub-zero regions.

22.3 Special mooring line heaters available upon request (48-hour notice required).

23. Ship Repair and Maintenance

23.1 Hot work permits require: (a) gas-free certificates (b) fire watch deployment (c) KPA safety officer inspection.

23.2 Underwater cleaning prohibited without environmental containment measures.

23.3 No tank cleaning facilities for chemical residues – nearest approved facility in Kitakyushu.

24. Crew Welfare Facilities

24.1 Seafarers’ Center located at 33-45 Nakamachi, Karatsu (open 0900-2100 daily).

24.2 Medical emergencies: Karatsu City Hospital (+81-955-72-3111) has 24/7 maritime trauma unit.

24.3 Currency exchange available at Mitsubishi UFJ Bank (1-1-1 Higashimachi) with seafarer ID.

25. Port State Control

25.1 Tokyo MOU inspection rate: 18% for foreign vessels (2023 data). Priority targets include:

– Ships >15 years old

– Bulk carriers with cement/clinker cargo

– Vessels with previous deficiencies

25.2 Common deficiencies: fire damper malfunctions, outdated nautical publications, improper garbage records.

26. Meteorological Services

26.1 Real-time weather updates broadcast on NAVTEX (518kHz) and VHF Ch 16/70 (DSC).

26.2 Typhoon warning stages:

– Stage 1 (300nm radius): Secure loose gear

– Stage 2 (150nm): Complete cargo ops

– Stage 3 (50nm): Evacuate non-essential personnel

26.3 Wave height warnings issued when exceeding 2.5m in approach channel.

27. Small Craft Regulations

27.1 Workboats must display 1m high “PORT SERVICE” markings on both sides.

27.2 Bunkering barges require double-hull construction and oil spill response kits.

27.3 No personal watercraft (jet skis, etc.) permitted within commercial port areas.

28. Dangerous Goods Storage

28.1 Class 1 (explosives) storage limited to maximum 48 hours at designated eastern containment area.

28.2 Refrigerated dangerous goods must maintain temperature logs with 1-hour intervals.

28.3 IMDG segregation rules strictly enforced – incompatible cargo separation verified by KPA inspectors.

29. Electronic Reporting

29.1 Mandatory digital submissions via:

– e-Navigation (Japan Coast Guard)

– JP-MARINE (Customs)

– MICS (Quarantine)

29.2 Backup paper documents must bear original stamps and signatures.

29.3 System downtime procedures: Fax reports to +81-955-73-1123 (KPA Operations).

30. Special Cargo Protocols

30.1 Oversized cargo (>5m width): Night transport requires police escort (request 72h prior).

30.2 Heavy lifts (>100t): Crane load charts must be verified by ClassNK surveyor.

30.3 Live animals: Veterinary inspection mandatory before discharge.

31. Vessel Waste Management

31.1 Oily water separator discharge must be recorded in ORB with 1ppm alarm test printouts retained for inspection.

31.2 Food waste disposal requires segregation from other garbage and prior notification to KPA sanitation office.

31.3 Incineration of ship-generated waste prohibited within port limits – use shore reception facilities only.

32. Port Entry/Exit Formalities

32.1 Final departure clearance requires:

– Port dues payment receipt

– Garbage disposal certificates

– Last minute crew list

32.2 Outbound vessels must submit ETA for next Japanese port via e-Navigation before departure.

32.3 Anchorage clearance procedures take minimum 2 hours – factor this into sailing plans.

33. Ship Chandler Services

33.1 Approved vendors list available at KPA administration building (updated quarterly).

33.2 Cash-on-delivery (COD) not permitted – all transactions require company purchase orders.

33.3 Bonded stores delivery requires customs escort – request 24 hours in advance.

34. Emergency Preparedness

34.1 Monthly emergency drills must include:

– Man overboard (port side)

– Main engine failure in channel

– Container fire scenarios

34.2 Emergency towing wires must be rigged on forecastle during entire port stay.

34.3 Abandon ship drills prohibited while berthed – use designated training areas only.

35. Cargo Securing Requirements

35.1 Timber deck cargo lashings must withstand 30° roll angle as per CSS Code.

35.2 Container stack weight limits enforced as per vessel’s Cargo Securing Manual.

35.3 Bulk cargo trimming certificates required for grain/ore shipments exceeding 5,000MT.

36. Radioactive Materials Handling

36.1 Class 7 cargo operations require:

– 500m exclusion zone

– Radiation monitoring team on standby

– Prior notification to Saga Prefecture Nuclear Safety Office

36.2 Transport vehicles must have IAEA Type B packaging certificates.

36.3 No simultaneous operations with foodstuff cargo allowed.

37. Port Infrastructure Limitations

37.1 Maximum air draft: 45m (restricted by Karatsu Ohashi Bridge clearance).

37.2 Shore power available only at Berth 3 (Central Wharf) – 6.6kV/60Hz capacity.

37.3 No LNG bunkering facilities – nearest available at Hakata Port.

38. Fishing Vessel Interactions

38.1 Seasonal fishing fleet concentrations occur March-May and September-November.

38.2 Minimum 0.5nm separation required when passing fishing fleets during net deployment.

38.3 Night fishing boats may not show proper lights – maintain enhanced lookout.

39. Historical Wreck Areas

39.1 Protected archaeological zone at 33°24.8’N 129°55.2’E (no anchoring/dredging).

39.2 Magnetometer surveys required for anchoring outside designated areas.

39.3 Discovery of artifacts must be reported immediately to Japan Coast Guard.

40. Final Checklist Before Departure

40.1 Verify:

– All mooring lines recovered

– Navigation equipment tested

– Port clearance documents received

40.2 Confirm next port requirements (especially for Australia/US-bound vessels).

40.3 Submit final crew list updates to immigration via NACCS system.

41. Vessel Traffic Monitoring

41.1 AIS must remain operational throughout port stay – shutdown requires KPA written approval.

41.2 Vessels at anchor must maintain VHF watch on Channel 16 with 15-minute position checks.

41.3 Automatic identification of fishing vessels (AIS Class B) often unreliable – maintain visual tracking.

42. Freshwater Supply

42.1 Potable water testing certificates required before connection (bacteriological/chemical).

42.2 Maximum filling rate: 50m³/hour with pressure not exceeding 4 bar at vessel’s manifold.

42.3 Water quality complaints must be reported within 1 hour of disconnection for investigation.

43. Shipboard Safety Equipment

43.1 Fire hoses must be rigged and pressurized during all cargo operations.

43.2 Pilot ladders require certification tags and must extend 1.5m above platform.

43.3 Emergency lighting must be tested and logged before night operations commence.

44. Port Working Hours

44.1 Standard working day: 0800-1700 JST with overtime rates applying for:

– Before 0600/after 2200 (150% surcharge)

– National holidays (200% surcharge)

44.2 No cargo operations permitted during Obon festival (August 13-15) without special permission.

45. Marine Pollution Prevention

45.1 Deck washdown water must be contained and tested before discharge.

45.2 No painting/surface preparation allowed without approved containment systems.

45.3 Bilge water sampling may be conducted randomly by Japan Coast Guard inspectors.

46. Special Area Regulations

46.1 No anchoring in marine protected areas (33°20′-33°30’N, 129°50′-130°05’E).

46.2 Cetacean observation required when transiting within 3nm of Hado-Misaki (April-October).

46.3 Seabird nesting areas (Takashima Island) – no spotlights or loud noises after sunset.

47. Vessel Manning Requirements

47.1 Minimum safe manning certificate must be posted in wheelhouse during port stay.

47.2 No single-officer bridge watches permitted while maneuvering in port limits.

47.3 Engine room must maintain watchkeeping standards equivalent to sea watches.

48. Cargo Survey Procedures

48.1 Independent surveyors must be registered with Japan Cargo Inspection Association (JCIA).

48.2 Draft surveys require calm conditions (wind <15 knots, no significant swell).

48.3 Dispute resolution follows Japan Commercial Arbitration Association rules.

49. Local Maritime Traditions

49.1 Annual Karatsu Kunchi festival (November 2-4) may cause port congestion – plan accordingly.

49.2 Fishing fleet ceremonies often occur at dawn – expect increased small boat activity.

49.3 Traditional wooden vessels have right-of-way in inner harbor areas.

50. Final Safety Reminders

50.1 Verify all cargo securing before departure – especially semi-containerized loads.

50.2 Confirm no crew members ashore before sailing – immigration fines up to ¥500,000 per case.

50.3 Last minute checks: navigation lights, whistle signals, and emergency gear readiness.

51. Tidal and Current Information

51.1 Maximum tidal range: 3.5m during spring tides (reference port: Hakata).

51.2 Strongest currents occur at narrows near Nakatsu Island (2.8 knots flood, 3.2 knots ebb).

51.3 Slack water periods last approximately 20 minutes – optimal for berthing maneuvers.

52. Vessel Dimension Restrictions

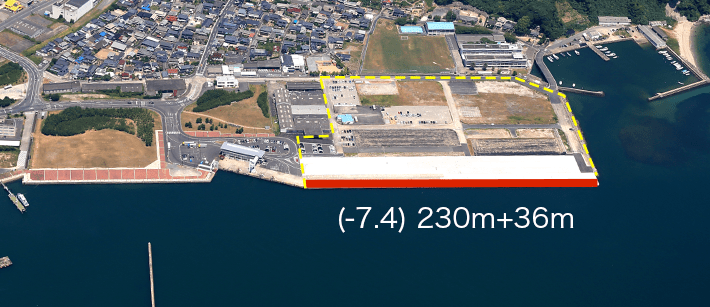

52.1 Maximum permissible dimensions for port entry:

– Length: 230m

– Beam: 40m

– Draft: 11.8m (at high water spring tides)

52.2 Air draft limited to 42m due to Karatsu Ohashi bridge clearance.

53. Night Navigation Procedures

53.1 Mandatory use of searchlights when maneuvering between 1800-0600 JST.

53.2 Additional lookout required on forecastle during night berthing operations.

53.3 No vessel movements permitted in inner harbor during heavy fog (visibility <500m).

54. Bunker Quality Control

54.1 All bunker deliveries must be accompanied by ISO 8217 compliant certificates.

54.2 Random sampling by Japan Ministry of Land, Infrastructure, Transport and Tourism (MLIT) may occur.

54.3 Dispute resolution for off-spec fuel must follow Japan Bunker Industry Association procedures.

55. Port Emergency Contacts

55.1 Port Control Emergency: VHF Ch 16 +81-955-73-1122 (24/7)

55.2 Oil Spill Response Team: +81-955-72-4555 (direct line)

55.3 Medical Emergency: Dial 119 (Japanese operators, request English interpreter)

56. Special Cargo Handling

56.1 Project cargo requires route survey conducted by KPA-approved surveyors.

56.2 Temperature-controlled cargo must maintain continuous monitoring with alarms.

56.3 Breakbulk cargo must be properly dunnaged to prevent wharf damage (minimum 15cm clearance).

57. Vessel Sanitation

57.1 Deratting certificates must be valid for entire port stay.

57.2 Vector control inspections conducted randomly by quarantine officers.

57.3 Galley waste must be stored in rodent-proof containers until disposal.

58. Local Weather Patterns

58.1 Prevailing winds: NW in winter (October-March), SE in summer (April-September).

58.2 Sudden squalls common during seasonal transitions (March-April, October-November).

58.3 Sea fog occurs most frequently May-July, typically clearing by midday.

59. Security Drills

59.1 ISPS security drills must be conducted within 24 hours of berthing.

59.2 Gangway watch must test duress alarms during each watch change.

59.3 All security incidents must be reported to Japan Coast Guard within 30 minutes.

60. Final Operational Notes

60.1 Verify all port charges are settled before departure to avoid delays.

60.2 Confirm next port ETA has been properly transmitted to relevant authorities.

60.3 Ensure all required documents (B/Ls, manifests, etc.) are properly filed and copies retained.

61. Anchorage Procedures

61.1 Designated anchorage areas marked on Admiralty Chart JP 1234 (updated 2024 edition).

61.2 Minimum anchoring depth: 20m with 5:1 scope required in typhoon season.

61.3 Anchoring watch must be maintained at all times with position verified hourly.

62. Hazardous Weather Protocols

62.1 Typhoon warning stage 1 (300nm): Commence securing all deck equipment.

62.2 Stage 2 (150nm): Complete cargo operations and prepare for possible evacuation.

62.3 Stage 3 (50nm): All non-essential personnel must disembark.

63. Navigation Equipment Requirements

63.1 Functional radar and ECDIS mandatory for entry/exit in restricted visibility.

63.2 Backup magnetic compass must be properly adjusted with current deviation card.

63.3 Portable VHF radios required for all mooring parties during berthing operations.

64. Port Authority Inspections

64.1 Routine inspections may cover: safety equipment, garbage records, and bunker samples.

64.2 Vessels with previous deficiencies will receive priority inspections.

64.3 Inspection results are recorded in the Tokyo MOU database within 24 hours.

65. Crew Change Procedures

65.1 Minimum 72-hour notice required for all crew changes.

65.2 New crew must present valid medical certificates and COVID-19 vaccination proof.

65.3 Immigration processing takes approximately 4 hours during business days.

66. Waste Oil Handling

66.1 Maximum transfer rate to reception facilities: 30m³/hour.

66.2 Oil record book entries must include receiving facility details and supervisor signature.

66.3 Unauthorized mixing of waste oil types strictly prohibited.

67. Electronic Navigation Updates

67.1 ENCs must be updated to latest edition before port entry.

67.2 Paper chart corrections should be current within last 3 months.

67.3 Temporary notices to mariners are posted on KPA website (updated weekly).

68. Port Laytime Calculations

68.1 Standard laytime commences 6 hours after NOR submission or upon berthing.

68.2 Demurrage rates: $4,500/day for first 3 days, $6,000/day thereafter.

68.3 Weather working days exclude periods with sustained winds above 28 knots.

69. Local Agent Responsibilities

69.1 Must accompany all official inspections and surveys.

69.2 Required to maintain 24/7 communication capability during vessel’s port stay.

69.3 Final departure documents must be verified before vessel sailing.

70. Final Compliance Checklist

70.1 Verify all required certificates are valid and onboard.

70.2 Confirm proper stowage of hazardous materials according to IMDG Code.

70.3 Ensure crew understands next port’s specific requirements and regulations.

71. Mooring Equipment Standards

71.1 All mooring lines must have minimum breaking strength of 120% vessel’s GT.

71.2 Synthetic ropes prohibited for permanent mooring – only permitted as surge lines.

71.3 Daily inspection of mooring winches and fairleads required during port stay.

72. Vessel Speed Restrictions

72.1 Maximum 6 knots within harbor limits (extending 2nm from port entrance).

72.2 Tugs must maintain 4 knots when making up alongside vessels.

72.3 No-wake speed (≤3 knots) enforced in small craft areas and near fishing zones.

73. Cargo Documentation

73.1 Original bills of lading must be surrendered before cargo release.

73.2 Dangerous goods declarations require Japanese/English bilingual format.

73.3 Outturn reports must be signed within 24 hours of completion.

74. Port Security Measures

74.1 ISPS Level 1: Single gangway with 24/7 watch.

74.2 ISPS Level 2: Additional patrols and restricted access zones.

74.3 All visitors must present photo ID and receive port security briefing.

75. Marine Communications

75.1 Primary working channels: VHF 12 (port operations), 14 (pilotage).

75.2 Emergency broadcasts repeated on NAVTEX (518 kHz) and Inmarsat-C.

75.3 Japanese language proficiency required for all bridge officers during maneuvers.

76. Bunkering Operations

76.1 Minimum 4-hour notice required for all bunker deliveries.

76.2 Simultaneous operations (SIMOPS) require KPA safety officer approval.

76.3 Barge connections must use ISO-compliant flanges with drip trays.

77. Port Health Regulations

77.1 Maritime Declaration of Health must be submitted 12 hours before arrival.

77.2 Crew medical checks available at port clinic (0800-2000 daily).

77.3 Rat guards mandatory on all mooring lines during extended stays (>48 hours).

78. Navigation Warnings

78.1 Temporary exclusion zones marked by yellow buoys during dredging operations.

78.2 Submarine cable areas shown on charts – anchoring prohibited.

78.3 Unlit fishing nets may be encountered outside main channels.

79. Customs Procedures

79.1 Crew personal effects declarations required for all personnel.

79.2 Ship’s stores inventory must match actual quantities onboard.

79.3 Narcotics detection dogs may conduct random inspections.

80. Final Departure Clearance

80.1 Verify all port charges settled with stamped receipts.

80.2 Confirm last crew member has boarded and immigration cleared.

80.3 Obtain final port clearance certificate from harbor master’s office.

81. Ballast Water Management

81.1 Ballast water exchange must be completed 200nm from nearest land (minimum depth 200m).

81.2 Treatment system must be operated and recorded in Ballast Water Record Book.

81.3 Port State Control may conduct random sampling of ballast water.

82. Vessel Maintenance Restrictions

82.1 Hot work requires permit from Port Authority and fire watch present.

82.2 Underwater cleaning/surveys must use approved contractors with containment systems.

82.3 No hull painting permitted during port stay except for touch-up repairs.

83. Tug Assistance Requirements

83.1 Minimum 2 tugs required for vessels over 20,000 GT during berthing/unberthing.

83.2 Tug lines must be properly tended with adequate fendering during operations.

83.3 Emergency towing arrangements must be clearly marked and accessible.

84. Cargo Handling Equipment

84.1 Shore cranes must display current load test certificates in operator cabin.

84.2 Container spreaders require daily inspection for cracks and twist lock condition.

84.3 Bulk loading chutes must have dust suppression systems operational.

85. Port Dues Calculation

85.1 Based on GT for first 24 hours, then pro-rated per 6-hour periods.

85.2 Environmental incentive discount available for vessels with Tier III engines.

85.3 Wharfage charges vary by cargo type (containers vs bulk vs general cargo).

86. Emergency Response Equipment

86.1 Oil spill kits must be positioned at all cargo transfer points.

86.2 Emergency shutdown systems tested within 12 hours of cargo operations.

86.3 Firefighting equipment must comply with latest SOLAS requirements.

87. Crew Welfare Facilities

87.1 Seafarer’s center provides free WiFi, showers and recreation (open 0800-2200).

87.2 Local SIM cards available at port gate security office.

87.3 Religious services available upon request through port chaplaincy.

88. Navigation Aid Maintenance

88.1 Report any malfunctioning aids to navigation immediately to JCG.

88.2 Temporary marks may be deployed during maintenance – check Notices to Mariners.

88.3 Light characteristics changed in 2024 – verify against current chart information.

89. Bunker Fuel Availability

89.1 IFO 380 available at all berths with 24-hour notice.

89.2 MGO available via truck delivery (minimum 50mt order).

89.3 LNG bunkering expected to be available Q3 2025 (currently not offered).

90. Final Operational Reminders

90.1 Conduct pre-departure safety meeting with all departments.

90.2 Verify all port documents are properly filed and copies retained onboard.

90.3 Submit final departure report via KPA’s online portal before sailing.

91. Dangerous Goods Handling

91.1 IMDG Code Class 1 explosives require special berth assignment and security escort.

91.2 Radioactive materials (Class 7) must have double approval from port and nuclear safety agency.

91.3 Toxic gas shipments (Class 2.3) require continuous gas monitoring during operations.

92. Port Entry Documentation

92.1 Advance Notice of Arrival must include last 10 ports of call with dates.

92.2 Crew list must indicate each seafarer’s CDC number and visa status.

92.3 Ship’s registry certificate must be notarized if vessel changed flag within 6 months.

93. Vessel Repair Services

93.1 Approved contractors list available from port authority website (updated monthly).

93.2 Dry docking available at nearby facility with 15,000-ton lift capacity.

93.3 Emergency repairs may be conducted alongside with prior permission.

94. Ice Navigation Procedures

94.1 Winterization measures required December-March (deck heating, pipe insulation).

94.2 Icebreaker assistance available with 72-hour notice during freezing conditions.

94.3 Special hull strength certification required for vessels operating in ice.

95. Port Environmental Regulations

95.1 Scrubber washwater discharge prohibited within port limits.

95.2 Underwater noise mitigation measures required for sensitive marine areas.

95.3 Ballast water sampling may be conducted by environmental inspectors.

96. Vessel Traffic Separation

96.1 Inbound vessels must use eastern lane, outbound use western lane.

96.2 Crossing traffic must request permission from VTS at least 30 minutes in advance.

96.3 Fishing vessels exempt from lanes but must maintain VHF watch on Channel 16.

97. Port Meteorological Services

97.1 Real-time weather updates broadcast every 30 minutes on VHF Channel 68.

97.2 Typhoon tracking maps available at port operations center.

97.3 Wave height predictions provided for outer anchorage areas.

98. Special Cargo Stowage

98.1 Heavy lift items (>100mt) require stowage plan approval 48 hours in advance.

98.2 Deck cargo must be secured to withstand 30° rolling in heavy seas.

98.3 Refrigerated containers must have functioning alarms and backup power.

99. Port Infrastructure Details

99.1 Main berths equipped with 100-ton bollards at 25m spacing.

99.2 Fendering system consists of D-type rubber fenders with 1.5m deflection.

99.3 Maximum permissible berth pressure: 30t/m².

100. Final Administrative Notes

100.1 All port fees must be settled in JPY or USD (credit cards accepted).

100.2 Crew changes require immigration processing at designated terminal.

100.3 Port authority reserves right to amend regulations with 30-day notice.

101. Vessel Clearance Procedures

101.1 Customs clearance available 24/7 for vessels with pre-submitted documentation.

101.2 Health clearance certificates must be presented in original copy with stamp.

101.3 Immigration processing for crew changes takes approximately 2 hours during working days.

102. Port Storage Facilities

102.1 Covered warehouse capacity: 150,000m² with temperature control options.

102.2 Open storage yards: 85 hectares with paved surfaces and drainage systems.

102.3 Dangerous goods storage: 12 specialized bunkers with 24-hour monitoring.

103. Pilotage Requirements

103.1 Compulsory pilotage for vessels over 500 GT or 50m in length.

103.2 Pilot boarding area: 2nm northeast of harbor entrance buoy (position 34°15’N 129°30’E).

103.3 Pilot ladder must comply with SOLAS standards and be properly illuminated at night.

104. Port Lighting Standards

104.1 Working areas illuminated to minimum 150 lux during night operations.

104.2 Navigational lights must be visible from all approach angles.

104.3 Emergency lighting tested weekly in all cargo handling areas.

105. Vessel Positioning Systems

105.1 Differential GPS available with accuracy to 10cm at all berths.

105.2 Radar reflectors required for vessels under 500 GT in poor visibility.

105.3 Automatic Identification System (AIS) must remain operational throughout port stay.

106. Cargo Securing Standards

106.1 Container lashing must follow IMO/ILO/UNECE Code of Practice.

106.2 Breakbulk cargo requires dunnage at minimum 10cm intervals.

106.3 Project cargo securing plans must be approved by class society.

107. Port Communication Protocols

107.1 English as working language for all vessel-port communications.

107.2 Emergency announcements will be repeated in Japanese and Chinese.

107.3 Digital notice board displays real-time operational updates at each berth.

108. Fresh Water Supply

108.1 Potable water available at all berths (tested monthly for quality).

108.2 Minimum 4-hour notice required for water bunkering operations.

108.3 Water meters must be sealed after delivery to prevent tampering.

109. Waste Management Services

109.1 Segregated waste reception facilities available at each terminal.

109.2 Hazardous waste must be properly labeled with UN numbers.

109.3 Food waste processing available (separate collection required).

110. Final Operational Checklist

110.1 Verify all cargo operations properly documented and signed.

110.2 Confirm all safety equipment restored to navigation condition.

110.3 Ensure port departure clearance certificate is received and filed.