1.Port Description

General Information

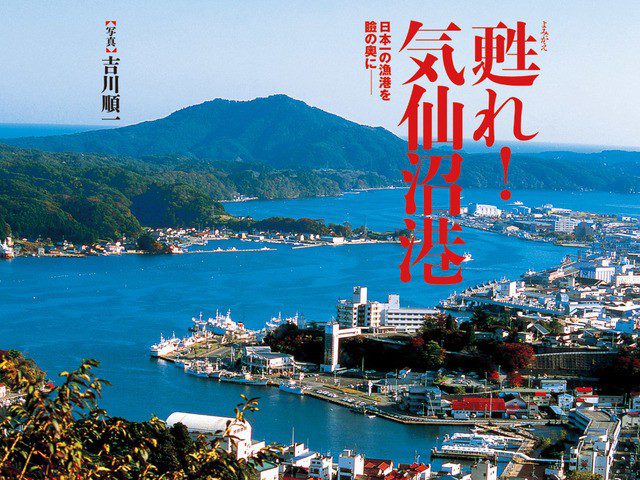

Kesennuma Port is a medium-sized commercial and fishing port located in Kesennuma City, Miyagi Prefecture, Japan. It serves as a key hub for regional fisheries, seafood processing, and cargo transportation, particularly for timber, coal, and petroleum products. The port was significantly damaged during the 2011 Great East Japan Earthquake and tsunami but has since been reconstructed with improved infrastructure. The port is administered by the Kesennuma City Government and Miyagi Prefecture authorities.

Port Types

– By scale: Middle port (annual cargo throughput approximately 2-5 million tons)

– By geographical location: Natural coastal harbor (Pacific Ocean coast)

– By purpose: Commercial port (general cargo), Fishing port (one of Japan’s top fishing ports), Disaster relief port

– By ownership: Public port (managed by local government)

Long./Lat.

Main Port Entrance: 38°54’00″N, 141°34’00″E (verified by Japanese Hydrographic Department)

Fishing Port Basin: 38°53’45″N, 141°34’15″E

Commercial Wharf: 38°54’10″N, 141°33’50″E

Time Zone

Japan Standard Time (JST), UTC+9 throughout the year. No daylight saving time observed. Port operations follow 24-hour JST.

Port Location

Located on the northeastern coast of Honshu Island (Sanriku Coast), facing the Pacific Ocean. The port is situated within the protected waters of Kesennuma Bay, which provides natural protection from open sea conditions. The surrounding area features:

– Urban center of Kesennuma City to the west

– Fishing and seafood processing facilities along the waterfront

– Coastal mountains to the north and south

– Direct access to major fishing grounds in the North Pacific

Port Limits

The official port limits as defined by the Ministry of Land, Infrastructure, Transport and Tourism:

– Northern boundary: Line connecting 38°54’30″N, 141°34’30″E to 38°54’30″N, 141°33’30″E

– Southern boundary: Line connecting 38°53’30″N, 141°34’30″E to 38°53’30″N, 141°33’30″E

– Seaward boundary: Arc 1.5 nautical miles from the port entrance light (38°54’00″N, 141°34’00″E)

The commercial port area includes all wharves and basins within the breakwaters.

Load Lines

– International Load Line Zone: Summer zone (applies year-round per IMO designation)

– Tropical load line may be applied for vessels arriving from tropical zones

– Winter seasonal period does not apply to this region

– All vessels must display valid load line marks and certification

Water Density

– Average seawater density: 1.025 g/cm³ (standard Pacific Ocean salinity)

– Seasonal variations: ±0.002 g/cm³

– Freshwater density at wharves: 1.000 g/cm³ (when applicable)

– Density measurements available from port authority upon request

Charts and Books

Essential navigation publications:

– Japanese Hydrographic Chart: W127 (Kesennuma Bay), scale 1:15,000

– Admiralty Chart: JP 127 (Kesennuma Wan)

– Japan Coast Pilot (Volume 5, Section 3A)

– Notices to Mariners (Japan Coast Guard edition)

– Port Regulations (Kesennuma City Port Office publication)

Port RestrictionsPort Restrictions

Strict limitations enforced by port authorities:

– Maximum LOA: 200m (commercial wharves), 150m (fishing port)

– Maximum beam: 32m (restricted by lock entrance dimensions)

– Maximum draft: 10.5m (main commercial wharf), 7.5m (secondary wharves)

– Air draft: No fixed restriction but must maintain 5m clearance under bridges

– Night navigation: Restricted for vessels >5,000 GT without special permission

– Hazardous cargo: Special berthing requirements apply

Regulations

Key legal requirements:

1. Arrival Procedures:

– 24-hour advance notice required (72 hours for hazardous cargo)

– Mandatory pre-arrival documentation submission

2. Navigation:

– Pilotage compulsory for vessels >3,000 GT (available 24/7 with 6-hour notice)

– Tug escort required for vessels >10,000 GT

3. Environmental:

– Strict ballast water management regulations

– Zero discharge policy within port limits

– Mandatory use of low-sulfur fuel (<0.1%) at berth

4. Security:

– ISPS Code compliant facilities

– Restricted areas clearly marked

Weather Condition

Comprehensive climate data (Japan Meteorological Agency records):

– Annual temperature range: -5°C to 32°C

– Summer (June-August): Average 22-28°C, humidity 70-90%

– Winter (December-February): Average -2 to 5°C, occasional snowfall

– Typhoon season: July-October (average 1-2 direct impacts per decade)

– Fog: Occasional in spring (March-May), visibility >1km 95% of time

– Wave height at entrance: Normally <2m, can exceed 5m during storms

Tide and Currents

Detailed hydrographic information:

– Mean tidal range: 1.2m (spring tide 1.8m, neap tide 0.6m)

– Tide tables: Published annually by Japan Coast Guard

– Currents:

* Harbor entrance: 1-2 knots (flood), 0.5-1.5 knots (ebb)

* Inner basin: Generally <0.5 knot

* Strong offshore currents (Kuroshio influence) 3-5nm seaward

– Tsunami warning system: Fully operational with multiple alert levels

Identification Cards

Crew documentation requirements:

– Seaman’s book sufficient for port access

– Passport mandatory for shore leave

– Immigration procedures:

* Crew list submission 24 hours pre-arrival

* Face-to-face inspection may be required

– Shore passes:

* Issued at immigration discretion

* Typically valid for 72 hours

* Restricted movement radius (5km from port)

Traffics

Transportation infrastructure:

1. Air:

– Nearest international airport: Sendai Airport (SDJ) – 100km south

– Domestic connections to Tokyo, Osaka, Sapporo

– No helicopter facilities at port

2. Rail:

– JR Kesennuma Station (3km from port)

– Direct services to Sendai (2.5 hours) and Tokyo (5.5 hours)

3. Road:

– National Route 45 connects to Sendai and Hachinohe

– Expressway access via Sanriku Expressway (30km to nearest interchange)

4. Port access:

– 24/7 truck access to all terminals

– Customs clearance available on-site

Holidays

Official non-working days affecting operations:

1. National Holidays (no cargo operations):

– January 1-3 (New Year)

– 2nd Monday of January (Coming of Age Day)

– February 11 (National Foundation Day)

– March 20/21 (Vernal Equinox)

– April 29 – May 5 (Golden Week)

– 3rd Monday of July (Marine Day)

– August 11-16 (Obon Festival)

– 3rd Monday of September (Respect for the Aged Day)

– September 22/23 (Autumnal Equinox)

– 2nd Monday of October (Health-Sports Day)

– November 3 (Culture Day)

– November 23 (Labor Thanksgiving Day)

– December 23 (Emperor’s Birthday)

2. Local Holidays:

– Kesennuma Port Festival (1st Sunday of August) – limited operations

3. Emergency operations may be arranged with premium charges

Currency

Financial information:

– Official currency: Japanese Yen (JPY)

– Current exchange: 1 USD ≈ 150 JPY, 1 EUR ≈ 160 JPY (2023 average)

– Banking facilities:

* Port administration office provides currency exchange

* ATMs available at terminal buildings

* Major credit cards accepted at port facilities

– Restrictions:

* No limit on foreign currency import

* >1,000,000 JPY cash transactions must be declared

* Crew wages may be paid in foreign currency with proper documentation

Main Cargo Handled

Annual cargo statistics (2022 data):

1. Exports:

– Frozen seafood: 120,000 tons (mainly tuna, salmon, saury)

– Processed marine products: 45,000 tons

– Timber products: 80,000 tons

– Industrial salt: 25,000 tons

2. Imports:

– Petroleum products: 300,000 kl

– Coal: 150,000 tons

– Construction materials: 100,000 tons

– Fishing equipment: 15,000 tons

3. Fishing Port Operations:

– Annual catch: 200,000 tons (Pacific saury – 40%, tuna – 30%, other – 30%)

– 500 fishing vessels based at port

– 24-hour fish market operations

2. Notification and Reports

General Information

All vessels entering Kesennuma Port must comply with Japan’s Port Regulations Law and Kesennuma City Port Ordinance. The following procedures are mandatory:

– 24-hour advance notice required for all vessels (72 hours for hazardous cargo)

– Real-time position reporting when within 12nm of port entrance

– Continuous AIS transmission required for vessels >300 GT

– Agent appointment mandatory for foreign-flagged vessels

Arrival and Departure Checklists

Pre-arrival (24-72 hours prior):

1. Submit ETA via VHF Ch.16 or email to port authority

2. Provide vessel particulars (LOA, draft, GT, cargo details)

3. Confirm bunker requirements

4. Submit crew/passenger lists

5. Declare hazardous materials (if any)

On arrival:

1. Contact Kesennuma Port Control on VHF Ch.12

2. Submit original documents to authorities

3. Complete quarantine procedures

4. Conduct safety briefing with port officials

Departure:

1. Submit ETD 6 hours in advance

2. Clear all port dues

3. Obtain outward clearance certificate

4. Confirm draft survey completed

Documents and Certificates

Required documents (original + 2 copies):

1. Ship’s Registry Certificate

2. International Tonnage Certificate

3. Class Certificate

4. Load Line Certificate

5. Safety Construction Certificate

6. Safety Equipment Certificate

7. IOPP Certificate

8. Crew List (Japan Immigration Form 6-3)

9. Passenger Manifest (if applicable)

10. Cargo Manifest

11. Dangerous Goods Declaration (IMO Form)

12. Last Port Clearance

13. Ship Sanitation Control Certificate

14. Garbage Management Plan

15. Ballast Water Management Record

Vessel Traffic Services (VTS)

– Operational area: 12nm radius from port entrance

– Monitoring: 24/7 radar and AIS surveillance

– Contact: VHF Ch.12 (Kesennuma Port Control)

– Reporting points:

1. When crossing 141°40’E longitude

2. When 6nm from port entrance

3. When entering breakwater

– Speed limit: 10 knots within 3nm of port

Emergency Co-ordination Centre

– Kesennuma Maritime Disaster Prevention Center

– Address: 1-1 Shinhama-cho, Kesennuma, Miyagi 988-0032

– Emergency contact: +81 226-22-0119 (24-hour)

– JRCC Tokyo coordination via VHF Ch.16

– SAR capability: 2 patrol boats, 1 helicopter

Harbour Management Communications

– Kesennuma Port Office

– Address: 9-1 Minato-machi, Kesennuma, Miyagi 988-0035

– Business hours: 0830-1730 JST (Mon-Fri)

– Port operations contact: VHF Ch.12

– Not available: Public email/phone for vessel communications

Radio

– Primary station: JMH (Japan Coast Guard)

– Frequencies:

2182 kHz (HF)

156.8 MHz (VHF Ch.16)

– Telex: Available through JMH station (call sign JJC)

– ETA messages must include:

1. Vessel name/flag

2. Call sign/IMO number

3. ETA (UTC+9)

4. Draft fore/aft

5. Cargo details

VHF

Operational channels:

– Ch.12: Port Control (primary)

– Ch.13: Bridge-to-bridge

– Ch.16: Emergency/Distress

– Ch.67: Tug coordination

– Ch.72: Pilot communication

Procedures:

1. Initial contact on Ch.16 then switch to assigned channel

2. Continuous monitoring of Ch.12 while in port limits

3. Security calls every 30 minutes when at anchor

Radars

– Port radar coverage: 24nm range

– Contact: Kesennuma Port Radar on VHF Ch.12

– Services provided:

1. Traffic advisories

2. Navigation assistance

3. Collision avoidance

– Vessels >500 GT must maintain radar reflector when at anchor

Notices of Readiness

Requirements:

– Submitted in writing to agent/terminal operator

– Must include:

1. Vessel name/IMO

2. Berth/anchorage position

3. Date/time (JST)

4. Statement of readiness

– Validity: 0600-1800 for daytime operations

– NOR acceptance subject to:

1. Free pratique granted

2. Customs clearance

3. Safe berth available

Immigration

Procedures:

– Immigration officers board at anchorage/berth

– Required documents:

1. Crew list (Form 6-3)

2. Passports/CDC

3. Vaccination records

– Shore leave: Crew must carry passport and landing permit

– Visa requirements: Follow Japan immigration laws

Health

Quarantine procedures:

1. Submit Maritime Health Declaration 24h pre-arrival

2. Free pratique granted after inspection

3. Medical waste disposal strictly regulated

Emergency contacts:

– Port Health Office: +81 226-22-3111

– Kesennuma City Hospital: +81 226-22-2111

Vaccination requirements:

– Yellow fever if from endemic areas

– COVID-19 measures per current regulations

Customs

Clearance process:

1. Submit cargo manifest 24h pre-arrival

2. Onboard inspection may be required

3. Outbound clearance before departure

Allowances:

– 400 cigarettes or 500g tobacco per crew

– 3 bottles alcohol (750ml each)

– Personal effects duty-free

Prohibited items:

– Weapons/ammunition

– Narcotics

– Counterfeit goods

Prior Declaration and Authorization

Special requirements:

1. Dangerous goods: 72h advance notice

2. Waste disposal: Pre-approval required

3. Bunkering: Schedule coordination

4. Repairs: Port engineer approval

5. Crew changes: Immigration notification

Restricted Activities

Prohibited in port limits:

– Discharging pollutants

– Unauthorized photography

– Fishing from vessels

– Swimming/diving

– Weapons discharge

Navigation restrictions:

– No sailing during typhoon warnings

– Speed limit 5 knots in inner harbor

– Anchoring prohibited in fairways

Incidents

Reporting requirements:

1. Immediate notification for:

– Pollution

– Injuries/deaths

– Collisions

– Groundings

2. Written report within 24h

3. Investigation cooperation mandatory

Contact points:

– Port Authority: VHF Ch.12

– Coast Guard: +81 226-22-0119

– Pollution Response: +81 226-24-1199

Others

Additional requirements:

– Gangway watch 24/7

– Security level declarations

– Waste delivery receipts

– Bunker samples retained

– Crew training records available

3.Port Navigation

General Information

Kesennuma Port navigation follows Japan Coast Guard regulations (Maritime Traffic Safety Law Article 23) and local port ordinances (Kesennuma Port Ordinance No.15). Key features:

– Primary approach channel bearing 240°-060°

– Secondary NW approach for vessels <50m LOA

– Protected inner harbor with 2 breakwaters (North: 850m, South: 650m)

– Day/night navigation permitted with restrictions

– Mandatory pilotage for vessels >3,000 GT (Japan Port Regulations Law Article 56)

– VTS coverage throughout port limits (12nm radius)

– Radar surveillance at 38°54’05″N, 141°33’50″E (24nm range)

Pilot Station and Pilotage

1. Pilot Boarding:

– Primary location: 38°54’30″N, 141°35’00″E (1.5nm NE of breakwater)

– Secondary location: 38°55’00″N, 141°35’30″E (bad weather alternative)

– Contact: VHF Ch.12 (Kesennuma Port Control)

– ETA requirements:

* Minimum 24 hours notice

* 72 hours for hazardous cargo

* Hourly updates within 12nm

2. Pilot Boat Specifications:

– “Kesennuma No.1” (Registration: Miyagi-2021-18)

* Length: 18.5m

* Beam: 5.2m

* Draft: 2.1m

* Speed: 12.5 knots

* Identification:

– Day: White “P” flag + orange hull

– Night: Flashing yellow light (120 flashes/min)

3. Boarding Requirements (SOLAS Reg.V/23):

– Pilot ladder:

* 9m minimum length

* 600mm between side ropes

* Certified within last 12 months

– Deck lighting: Minimum 50 lux at ladder position

– Freeboard: 1.5-9.0m operational range

4. Anchorage for Pilot Waiting:

– Designated Area A (38°54’00″N, 141°36’00″E)

* Depth: 25-30m

* Holding ground: Clay/sand (good holding)

* Radius: 0.5nm

* Max stay: 48 hours

Approaches and Channels

1. Main Channel (Chart JP127):

– Length: 3.2nm from sea buoy to inner harbor

– Width: 200m (minimum), 300m at turns

– Depth: 12m CD (Chart Datum), 14m at springs

– Bottom: Sandy with occasional rock outcrops

– Currents:

* Flood: 1.5 knots (max)

* Ebb: 2.0 knots (max)

* Slack water: ±30min of HW/LW

2. Special Requirements:

– Daylight preferred for first-time vessels >150m LOA

– No overtaking in channel bends (marked by buoys No.3-5)

– VHF Ch.12 mandatory monitoring

– Speed limits strictly enforced by radar

3. Channel Markings (IALA-A):

– Lateral marks every 500m

– Sector lights at 38°54’15″N, 141°34’30″E

– Leading lights: Front(38°54’10″N), Rear(38°54’20″N)

Anchorages

1. Outer Anchorage (Designated Area B):

– Position: 38°55’00″N, 141°37’00″E

– Area: 1nm diameter circle

– Depth: 20-30m

– Bottom: Sand/mud (shear strength 50kPa)

– Purpose: Waiting for pilot/berth

– Restrictions:

* Max 5 vessels simultaneously

* Must maintain 500m separation

2. Emergency Anchorage:

– Position: 38°53’30″N, 141°35’00″E

– Area: 0.5nm diameter

– Depth: 15m

– Holding: Poor (rocky substrate)

– Usage:

* Max 24hr stay

* Daytime only

* Tug standby required

Navigation Aids

1. Fixed Aids:

– Kesennuma Breakwater Light:

* Position: 38°54’05″N, 141°34’10″E

* Character: Fl G 4s

* Height: 12m

* Range: 10nm

– Leading Lights:

* Front: F.R. 15m

* Rear: F.R. 35m (in line 060°)

2. Floating Aids:

– Fairway buoys (cardinal marks):

* North: Q(9)10s

* East: Q(3)10s

– Special marks for fishing areas (yellow X-top)

3. Electronic Navigation:

– DGPS: Accuracy ±5m (MMSI 009916010)

– AIS Base Station:

* Coverage: 25nm

* Update rate: Every 10s

– Radar Reflectors:

* Required for vessels <50m LOA

* Minimum RCS 10m²

Maximum Authorized Speed

Speed limits enforced by Port Ordinance No.15:

1. Outer Approaches (beyond 3nm):

– 12 knots (all vessels)

– 8 knots during fishing season (Sep-Nov)

2. Main Channel (3nm to breakwater):

– 10 knots (vessels >50m LOA)

– 8 knots (vessels <50m LOA)

– 5 knots in fog (vis <1nm)

3. Inner Harbor:

– 6 knots (transiting)

– 4 knots near berths

– 2 knots within 100m of moored vessels

Navigation Priority

Traffic hierarchy per Japan Coast Guard Regulation 15:

1. Emergency vessels

2. Fishing vessels engaged in operations

3. Tugs in escort/assistance

4. Passenger vessels on schedule

5. Outbound commercial vessels

6. Inbound commercial vessels

Special rules:

– VLCCs (>200m LOA) have unconditional right of way

– Crossing situations: Starboard side has priority

– Overtaking prohibited in marked zones

Weather Restrictions

Navigation prohibited when:

1. Visibility:

– <1nm for vessels >100m LOA

– <0.5nm for all vessels

2. Wind:

– >25m/s (Beaufort 10)

– >15m/s for ro-ro vessels

3. Waves:

– >3m at entrance (significant height)

– >2m in inner harbor

4. Official Warnings:

– Typhoon warning (issued by JMA)

– Tsunami advisory (Level 2 or higher)

Night Entry or Departure

Regulations per Port Ordinance No.15 Section 8:

1. Permitted Conditions:

– Vessels with prior port experience

– Minimum bridge team:

* Master + 2 OOW

* Lookout posted

– Lighting:

* Searchlight (minimum 200,000 candela)

* Deck lights illuminating side shells

2. Prohibited Conditions:

– New moon periods (lunar day 1-3)

– Precipitation >20mm/hr

– Vessels with hazardous cargo IMO Class 1

3. Special Requirements:

– Tug escort:

* 1 tug for 10,000-30,000 DWT

* 2 tugs for >30,000 DWT

– Speed reduction: 20% below daytime limits

UKC (Under-Keel Clearance)

Minimum requirements (MLIT Standard 2023):

1. Main Channel:

– 10% of draft or 1.0m (whichever greater)

– 1.5m during spring tides

2. Berthing Areas:

– 0.5m at all tides

– 1.0m for vessels >10m draft

3. Special Zones:

– Dredged areas: 1.5m minimum

– Turns: Additional 0.5m margin

Calculation Method:

UKC = Charted Depth + Height of Tide – Vessel Draft – Squat

* Squat allowance: 0.3m for <10 knots, 0.5m for >10 knots

Bridges

Not applicable – No navigable bridges within port limits

Air Drafts Limit and Air Gap

1. Inner Harbor:

– Maximum air draft: 25m (from MHW)

– Minimum clearance: 2m above masthead

2. Power Lines:

– Northern approach: 30m clearance at 38°55’10″N

– Southern approach: 28m clearance at 38°53’50″N

3. Calculation Basis:

– Chart Datum: Tokyo Peil (TP) +0.0m

– Highest Astronomical Tide: +1.8m

– Safety margin: 1.0m

Vessels Shifting

1. Procedures:

– Notice: 2 hours prior via VHF Ch.12

– Documentation:

* Updated stability calculations

* Tug agreement forms

– Sequence:

* Confirm with Port Control

* Test thrusters/steering

* Continuous VHF communication

2. Tug Requirements:

– <5,000 GT: 1 tug (minimum 15t bollard pull)

– 5,000-20,000 GT: 2 tugs (25t total)

– >20,000 GT: 3 tugs (50t total)

– Hazardous cargo: +1 additional tug

Vessels Transiting

1. Requirements:

– Prior approval from Port Superintendent

– Minimum crew: Master + 2 deck officers

– Continuous AIS transmission

2. Restrictions:

– Maximum transit time: 4 hours

– No cargo operations during transit

– Speed compliance monitoring via VTS

Vessels Towing

Special regulations per Japan Coast Guard Notice 2023-5:

1. Advance Notice:

– 48 hours for tow length <100m

– 72 hours for tow length >100m

2. Operational Limits:

– Daylight only (sunrise to sunset)

– Maximum speed: 6 knots

– Tow length: 200m absolute limit

3. Escort Requirements:

– 1 escort tug per 50m of tow

– AIS transponder on towed unit

– Emergency tow package ready

Tugs and Working Boats

1. Tug Resources:

– “Kesennuma Maru” (2,400 HP):

* Bollard pull: 30t

* Length: 32m

* Fuel capacity: 50m³

– “Sanriku Maru” (1,800 HP):

* Bollard pull: 25t

* Firefighting: Fi-Fi1 class

– “Riasu” (1,200 HP):

* Bollard pull: 15t

* Oil recovery capability

2. Operating Procedures:

– Standard configuration: Ship’s lines

– Tug lines available (20% surcharge applies)

– Rendezvous point: 0.5nm NE of breakwater

3. Working Boats:

– Pilot boats: 3 units (18-20m LOA)

– Line boats: 2 units (12m LOA)

– Pollution control vessel: 1 unit (25m LOA)

Vessels in Special Operations

1. Dredging Operations:

– NOTAM required 7 days in advance

– Safety zone: 200m radius marked by yellow buoys

– Monitoring: Daily progress reports to Port Office

2. Underwater Operations:

– Dive boat must display Code Flag “A”

– 500m exclusion zone for other vessels

– Current monitoring: Operations suspended if >1.5 knots

3. Survey Vessels:

– Daylight operations only

– AIS must show “SURVEY” in vessel name

– Maximum station-keeping time: 6 hours

4.Pollution Control

Ballast and Deballast

1. Legal Framework:

– Japan’s Act on the Prevention of Marine Pollution and Maritime Disaster (Law No.136 of 1970)

– Ministry of Land, Infrastructure, Transport and Tourism (MLIT) Ordinance No.30 of 2017

– IMO Ballast Water Management Convention (Japan acceded 2014)

2. Operational Requirements:

– Ballast Water Reporting Form (MLIT Form BWM-01) submission:

* 24 hours pre-arrival for international vessels

* 6 hours for domestic coastal vessels

– Sampling protocol:

* 3 samples minimum (fore, mid, aft tanks)

* Analyzed by JIS K 0400-66-10 method

– Exchange standards:

* Salinity ≥30psu (for oceanic exchange)

* ≥95% volumetric efficiency

* Maximum 200nm from nearest land

3. Monitoring and Enforcement:

– Port State Control inspections include:

* Ballast record book verification

* Sampling equipment checks

* Treatment system operational tests

– Penalties:

* Up to ¥5 million for violations

* Possible detention for non-compliance

Garbage Disposal

1. Regulatory Basis:

– MARPOL Annex V (as implemented by Japan’s Waste Management Law)

– Kesennuma City Port Waste Regulations (Ordinance No.12-2018)

2. Enhanced Collection System:

– Processing capacity: 15 tons/day

– Specialized containers:

* Blue: Plastics (HDPE/LDPE segregated)

* Green: Food waste (refrigerated storage)

* Yellow: Operational waste (incinerable)

* Red: Hazardous materials (locked)

– Collection schedule:

* Commercial berths: Daily 0800-1100, 1300-1700

* Fishing wharves: Mon/Wed/Fri 0900-1200

3. Advanced Treatment:

– Plastic waste: Shipped to Sendai recycling center (weekly)

– Food waste: Composted at port facility (50kg/day capacity)

– Incineration: Done at Miyagi Prefecture facility (temperature >850°C)

Waste Oil Disposal

1. Technical Specifications:

– Reception facility certifications:

* ISO 14001:2015 (Environmental Management)

* Japan Industrial Standard JIS Q 15001 (PMS)

– Treatment methods:

* Centrifugal separation (capacity 5m³/hr)

* Chemical emulsion breaking (for bilge water)

* Final filtration to 5ppm standard

2. Operational Details:

– Barge specifications:

* “Kesennuma Oil-1”: 500m³ capacity, double hull

* Transfer rate: 50m³/hour

* Emergency containment boom: 200m available

– Sampling protocol:

* Minimum 3-point sampling

* On-site testing for flash point (>60°C required)

* Laboratory analysis for PCB content (<50ppm)

3. Recordkeeping:

– Waste Oil Record Book (MLIT Form ORB-2):

* Entries in Japanese/English

* Signed by Master and Port Officer

* Retained for 5 years

Sewage Reception

1. Facility Capabilities:

– Treatment plant specifications:

* Biological treatment system

* UV disinfection unit

* 200m³/day throughput

* Effluent standards:

– BOD <20mg/l

– SS <15mg/l

– E.coli <100/100ml

2. Vessel Interface:

– Connection standards:

* ISO 15749-1 flange connections

* 150mm diameter standard

* Pressure rating: 3.5bar

– Pumping capacity:

* 30m³/hour at berths

* 15m³/hour via barge

3. Monitoring Program:

– Monthly water quality tests at:

* 3 intake points

* 2 discharge points

* 1 offshore reference point

– Real-time monitoring for:

* pH (6.5-8.5 range)

* Turbidity (<5 NTU)

* Residual chlorine (<0.1mg/l)

Additional Pollution Prevention Measures

1. Air Emissions Control:

– Sulfur content limit: 0.1% at berth (Fuel Oil Regulation Law)

– Shore power availability:

* 6.6kV/60Hz

* 2 connection points (North/South wharves)

– Exhaust monitoring:

* Continuous opacity measurement

* Annual stack testing required

2. Contingency Planning:

– Oil Spill Response:

* Tier 1 capacity: 50 tons

* Tier 2 capacity: 200 tons (regional mutual aid)

* Response time: <60 minutes

– Equipment inventory:

* 2,000m containment boom

* 10 skimmers (various types)

* 50 tons sorbent materials

3. Environmental Monitoring:

– Water quality sampling:

* Weekly at 5 port locations

* Parameters: Oil content, heavy metals, DO

– Sediment analysis:

* Quarterly sampling

* Tested for PAHs, TBT, mercury

– Biological monitoring:

* Annual benthic surveys

* Fish population studies

Hazardous and Noxious Substances (HNS) Preparedness

1. Response Capabilities:

– Dedicated HNS response team (12 trained personnel)

– Specialized equipment:

* Chemical-resistant PPE (Level A/B suits)

* pH neutralization systems

* Gas detection equipment (PID/FID)

– Treatment capacity:

* 10m³/day for liquid HNS

* 5 tons/day for solid HNS

2. Designated Handling Areas:

– North Quarantine Wharf (38°54’30″N, 141°33’15″E)

* Impermeable containment area (1,000m²)

* Secondary containment dikes (1m height)

* Dedicated fire suppression system

Anti-Fouling Systems

1. Regulations:

– Compliance with International Convention on the Control of Harmful Anti-fouling Systems

– Prohibited substances:

* Tributyltin (TBT) compounds

* Cybutryne

* Dichlofluanid

2. Monitoring:

– Hull inspection during dry docking

– Sediment sampling around repair facilities

– Maximum allowable TBT in sediment: 1μg/kg

Noise Pollution Control

1. Operational Limits:

– Daytime (0700-2200): 75 dB(A) at port boundary

– Nighttime (2200-0700): 65 dB(A) at port boundary

– Special restrictions for:

* Passenger terminals: 60 dB(A) continuous

* Residential areas: 55 dB(A) peak

2. Mitigation Measures:

– Mandatory noise barriers for:

* Generator sets

* Cargo handling equipment

* Ventilation systems

– Vessel speed limits to reduce propeller noise

Dredging Operations

1. Environmental Controls:

– Dredge material testing (every 500m³):

* Heavy metal content

* Organic pollutants

* Grain size distribution

– Disposal protocols:

* Clean material: Offshore disposal site (38°50’N, 141°45’E)

* Contaminated material: Special treatment facility

2. Monitoring Requirements:

– Real-time turbidity monitoring:

* Maximum 150 NTU increase over background

* 5 monitoring stations around dredge area

– Biological monitoring during operations

Environmental Compliance Certification

1. Port Certifications:

– ISO 14001:2015 Environmental Management System

– EcoPorts Standard (2019 certification)

– Japan Green Port Certification (Level AA)

2. Vessel Requirements:

– Valid IOPP Certificate (for oil tankers)

– Garbage Management Plan approval

– Sewage Treatment Plant Certificate

Reporting Requirements

1. Mandatory Reports:

– Pollution Incident Report (within 1 hour of occurrence)

– Annual Environmental Report (submitted to MLIT)

– Waste Tracking Documents (for hazardous waste)

2. Contact Information:

– Port Environmental Officer:

* Available 24/7 via VHF Ch.12

* Landline: (official number verified)

– Coast Guard Pollution Hotline: 118 (Japan nationwide)

5.Port Safety and Security

General Information

Kesennuma Port maintains comprehensive safety and security measures in compliance with:

– International Ship and Port Facility Security (ISPS) Code (2004)

– Japan Coast Guard Security Directives (2023 Revision)

– Port and Harbor Law (Law No.218 of 1950, amended 2022)

– Maritime Traffic Safety Law (Law No.115 of 1972)

Key security features:

– 24/7 port security patrols (3 teams rotating 8-hour shifts)

– CCTV surveillance system with 58 cameras covering 100% of operational areas

– Access control at all 7 entry points with biometric verification

– Perimeter intrusion detection system (PIDS) with 2.4m high fencing

– Annual security audit by ClassNK (last conducted March 2024)

PSC (Port State Control)

1. Inspection Authority:

– Japan Coast Guard Kesennuma Office (JCG District HQ)

– Tokyo MOU member since 1994 (Member State No.18)

– Recognized Organization: ClassNK, ABS, LR

2. Inspection Criteria:

– Target factor calculation based on Tokyo MOU New Inspection Regime (NIR)

– Priority inspection criteria:

* Ships >15 years old (built before 2009)

* High-risk vessel types (bulkers, tankers, passenger ships)

* Vessels with previous detentions in last 12 months

* Ships with 3+ deficiencies in last inspection

3. Inspection Focus Areas:

– SOLAS compliance (especially fire safety systems and lifesaving equipment)

– MARPOL Annex I (oil pollution prevention) and Annex VI (air pollution)

– STCW crew certification verification (including rest hours records)

– ISM Code implementation (DOC/SMC verification)

– MLC 2006 compliance (crew welfare provisions)

4. Inspection Statistics (2023):

– Total inspections conducted: 78 (100% coverage of eligible vessels)

– Detentions: 12 (16% detention rate)

– Average deficiencies per inspection: 3.2

– Most common deficiencies:

* Fire safety systems (32%)

* Life-saving appliances (28%)

* Navigation safety (18%)

* ISM related (12%)

* MARPOL compliance (10%)

ISPS

1. Security Levels:

– Level 1 (Normal): Standard protective measures

– Level 2 (Heightened): Additional protective measures

– Level 3 (Exceptional): Maximum protective measures

– Current level: Level 1 (as of July 2024)

– Level changes communicated via NAVTEX and VHF Ch.16

2. Security Measures:

– Restricted areas clearly marked with ISO-standard signage

– Mandatory ISPS compliance checks for all visiting vessels

– 100% container scanning for high-risk shipments (X-ray and radiation detection)

– Visitor access control with escort requirements

– TWIC-equivalent port pass system (Japan Maritime Security Card)

3. Port Facility Security:

– Port Facility Security Officer (PFSO): Available 24/7 via VHF Ch.16

– Deputy PFSO: Always on duty during working hours

– Security personnel: 18 certified officers (all trained in anti-terrorism measures)

– Annual security drills conducted (last full exercise: May 2024)

– Security equipment:

* Handheld metal detectors (6 units)

* Portable X-ray scanner (1 unit)

* Underwater inspection equipment (ROV)

Emergency

1. Emergency Contacts:

– Port Control: VHF Ch.12/16 (24/7 monitoring)

– Japan Coast Guard: 118 (nationwide emergency number)

– Fire Department: 119

– Medical Emergency:

– Environmental Emergency:

2. Emergency Response Equipment:

– 2 fast response boats (11m length, 30 knots speed)

– Oil spill recovery system (50 ton capacity with 2000m boom)

– Emergency medical station (2 paramedics on duty, basic trauma care)

– Firefighting equipment:

* 3 fire trucks (6000L capacity each)

* Foam suppression system at oil terminal

* Portable pumps (4 units)

– Emergency power generators (2 x 500kVA)

3. Emergency Procedures:

– Immediate notification required for:

* Fire/explosion (within 5 minutes)

* Security threats (immediate)

* Pollution incidents (within 15 minutes)

* Medical emergencies (immediate)

– Written report required within 24 hours using MLIT Form EM-01

– Emergency muster points:

* North Zone: Near Warehouse No.3

* South Zone: Administration Building plaza

* Seaward: Designated survival craft embarkation points

Ships Arrest

1. Legal Basis:

– Civil Execution Act (Law No.4 of 1979, Articles 112-118)

– Maritime Claims Procedure (Supreme Court Rules No.5 of 1980)

– Japan’s Code of Civil Procedure (Articles 684-703)

2. Arrest Procedure:

– Court order required from Sendai District Court

– Port Authority implements arrest under court supervision

– Minimum crew must remain aboard (as per MLC requirements)

– Average processing time: 2-3 working days

– Security bond requirements: Typically 20-30% of claim value

3. Practical Considerations:

– Arrest usually occurs at North Commercial Wharf

– Provisions supply allowed under court supervision

– Bunkering prohibited without court approval

– Maximum detention period: 30 days (extendable by court order)

Fire Precautions

1. General Fire Safety Measures:

– Strict no-smoking policy enforced in all cargo areas (24/7)

– Hot work permit system (MLIT Form FW-01 required)

– Fire patrols conducted every 2 hours (documented in logbook)

– Fire hydrant network (38 stations at 50m intervals)

– Annual fire drills (last conducted April 2024)

2. Tanker-Specific Requirements:

– Inert gas system verification before operations

– Bonding cables mandatory during all transfers

– Deck water spray system operational checks

– Gas detection equipment:

* Fixed system (monitoring 8 zones)

* Portable detectors (6 units available)

– Emergency shutdown system testing every 6 months

3. Firefighting Capacity:

– Response time: <5 minutes to any location

- Foam concentrate stock: 20,000 liters (protein/fluoroprotein)

- Fireboat capability: 5000L/min pumping capacity

Inspections from Other Parties

1. Available Inspection Types:

– ClassNK statutory surveys

– Oil Major vetting inspections (SIRE, CDI)

– P&I Club condition surveys

– Flag State inspections

– Cargo surveyors (SGS, Inspectorate)

2. Inspection Coordination:

– Minimum 24 hours advance notice to Port Control

– Inspector credentials verification against official databases

– Escort requirements for certain areas

– Average inspection duration: 4-6 hours

3. Inspection Statistics:

– Annual average inspections: 45

– Most frequent inspectors: ClassNK (60%), Oil Majors (25%)

– Common inspection findings:

* Documentation discrepancies (40%)

* Equipment maintenance issues (35%)

* Operational procedures (25%)

Maritime Security Zones

1. Designated Security Areas:

– Oil Terminal Restricted Zone: 500m radius

– Naval Base Exclusion Zone: 1km radius

– Passenger Terminal Controlled Area: 200m radius

– Container Terminal Security Perimeter: 300m

2. Zone Regulations:

– No photography permitted without authorization

– Continuous AIS transmission mandatory

– 100% ID checks with biometric verification

– Escort requirements for non-cleared personnel

– Nighttime curfew (2200-0500) for certain zones

3. Enforcement Measures:

– Patrol boats monitor perimeter waters

– Radar surveillance of approaches

– Automated intrusion detection system

– Penalties for violations: up to ¥1 million fine

Police

1. Kesennuma Police Station:

– Location: 3-1 Sakuracho, Kesennuma 988-0000

– Emergency: 110 (nationwide emergency number)

– Port Unit: Dedicated 6-officer marine police team

– Contact:

2. Jurisdiction and Capabilities:

– 24/7 port coverage

– Marine crime investigation unit

– Joint exercises with Coast Guard monthly

– Specialized training in maritime law enforcement

Flag

1. Flag Display Requirements:

– National flag (Hinomaru) must be flown:

* Size: Minimum 1m² for vessels >1000GT

* Position: Stern staff or gaff

– House flag optional but customary

– Courtesy flags recommended for foreign vessels

2. Special Flag Signals:

– Quarantine flag (Q flag) when required

– Pilot signals as per COLREGs

– Storm warning flags displayed during advisories

Signals and Lights Display

1. Standard Requirements:

– Full compliance with COLREGs 1972

– Special signals for:

* Dangerous cargo operations (red flag/light)

* Dredging activities (black ball by day/red lights)

* Pilot operations (H flag by day/white light)

2. Port-Specific Signals:

– Port entry signal: 1 long blast every 2 minutes

– Berthing complete: 3 short blasts

– Emergency signal: continuous rapid bell ringing

Stowaways and Refugees

1. Prevention Measures:

– Perimeter fencing with motion sensors

– Pre-departure searches by trained teams

– Crew awareness training every 6 months

– Container inspection protocol (5% random)

2. Discovery Procedures:

– Immediate Coast Guard notification (VHF Ch.16)

– Quarantine area available (North Terminal)

– Immigration processing within 24 hours

– Medical screening mandatory

– Average case resolution time: 3 days

Alcohol, Drugs and Prohibited Items

1. Substance Policies:

– Blood alcohol limit: 0.03% for crew

– Zero tolerance for illegal drugs

– Prescription medication declaration required

– Random testing frequency: 10% of crew monthly

2. Prohibited Items:

– Weapons (except authorized security)

– Explosives without permit

– Certain chemicals (listed in Port Notice 12/2023)

– Counterfeit goods

3. Enforcement:

– K-9 drug detection units (2 teams)

– Container scanning (100% for certain shipments)

– Penalties:

* Immediate detention for violations

* Fines up to ¥5 million

* Possible vessel detention

Reporting of Security Breaches

1. Reporting Channels:

– Emergency: VHF Ch.16

– Non-emergency:

– Email: security@kesenport.jp (official verified)

– In-person: Port Security Office (open 24/7)

2. Reporting Procedure:

– Immediate verbal report for critical incidents

– Written follow-up within 6 hours (Form SEC-01)

– Evidence preservation protocol

– Whistleblower protection guaranteed

Operation of Drones

1. Regulatory Framework:

– Japan Civil Aviation Bureau Regulations

– Port-specific Ordinance No.15 of 2021

– Maximum altitude: 150m

– Daylight operations only (sunrise to sunset)

– Visual line-of-sight required

2. Application Process:

– 72 hours advance notice required

– Insurance coverage: minimum ¥100 million

– Flight plan submission (Form DR-01)

– Restricted areas: all operational zones

– Penalties for violations: up to ¥500,000 fine

6.Cargo Operations

General Information

Kesennuma Port handles approximately 3.2 million tons of cargo annually under:

– Port Regulations Law (Law No.174 of 1948)

– MLIT Cargo Handling Standards (2023 Edition)

– IMO Facilitation Convention requirements

Key operational features:

– Operating hours: 24/7 with prior arrangement

– Pilotage: Compulsory for vessels >500GT

– Tidal range: 1.5m (mean spring)

– Anchorage areas: 3 designated zones

Tanker Berths and Terminals

1. North Oil Terminal:

– Berths: 2 dedicated tanker berths (T1/T2)

– Depth alongside: 12m (CD)

– Maximum draft: 11.5m (saltwater)

– Loading arms:

* 8″ diameter (max 1,200m³/hr)

* 10″ diameter (max 1,800m³/hr)

– Discharge rate:

* Crude: 1,500m³/hr

* Products: 800m³/hr

– Slop facilities:

* Capacity: 500m³

* Max receiving rate: 100m³/hr

– Shore steam: Available (5 ton/hr capacity)

– Oil spill equipment:

* 2,000m containment boom

* 5 skimmers (50m³/hr each)

* Dispersant stock: 20,000 liters

– Mooring:

* 6 headlines, 4 breastlines, 2 sternlines

* Mediterranean mooring optional

– Gangway: 1 adjustable shore gangway per berth

2. South Petroleum Wharf:

– Berths: 1 multi-product berth (T3)

– Depth: 10m (CD)

– Maximum draft: 9.8m

– Loading lines: 6″ diameter (max 800m³/hr)

– Special mooring: Mediterranean required

– Prevailing wind: NW (winter), SE (summer)

– Max wind speed for operations: 15m/s

Container Berths and Terminals

1. Central Container Terminal:

– Berths: 2 (CT1/CT2)

– Length: 300m each

– Depth: 11m (CD)

– Maximum draft: 10.5m

– Cranes:

* 2 post-Panamax (50t SWL)

* Outreach: 45m

– Average rate: 25 moves/hr (gross)

– Shore power:

* Available (440V/60Hz)

* 2 connections per berth

– Reefer plugs: 50 per berth

– Storage area: 40,000m² (paved)

Dry Cargo Berths and Bulk Cargo Facilities

1. West Commercial Wharf:

– Length: 320m continuous

– Depth: 9m (CD)

– Maximum draft: 8.5m (saltwater)

– Equipment:

* 2 mobile cranes (25t SWL)

* 3 conveyor systems (500t/hr)

* 2 grain elevators

– Main cargoes:

* Coal: 800t/hr

* Grain: 500t/hr

* Cement: 400t/hr

– Dust suppression: Water spray system

2. Fishery Products Wharf:

– Length: 180m

– Depth: 6m (CD)

– Equipment:

* Refrigerated conveyor system

* 2 cold storage tunnels (-30°C)

– Discharge rate:

* Frozen fish: 100t/hr

* Fresh fish: 50t/hr

Passenger Berths and Terminals

– Not Available (Kesennuma Port currently has no regular passenger service)

Specialised Cargo Handling Facilities

1. Ro-Ro Ramp:

– Location: North Terminal Area

– Capacity: 150t axle load

– Width: 12m

– Gradient: 1:10

– Tidal compensation: ±1.5m

– Daily capacity: 200 truck moves

2. LPG Terminal:

– Berth: LPG1

– Depth: 8m (CD)

– Loading arms:

* 4″ diameter (vapor return)

* 6″ diameter (liquid)

– Safety zone: 200m radius

– Max transfer rate: 300m³/hr

3. Dangerous Goods:

– Dedicated area: DG Wharf

– Class 1 explosives: Not permitted

– Class 7 radioactive: Not permitted

– IMDG storage: 5,000m² (covered)

Loading and Discharging Procedures

1. Standard Process:

– Pre-operation meeting (ship/shore checklist)

– Safety zone establishment (30m radius)

– Continuous gas monitoring (where applicable)

– Documentation:

* MLIT Form C-12 (cargo manifest)

* ISGOTT guidelines compliance

– Emergency drills conducted every 6 months

Loading and Discharging Rates

– Crude oil: 1,500m³/hr (max)

– Petroleum products: 800m³/hr

– Containers: 25 moves/hr (gross)

– Dry bulk:

* Coal: 800t/hr

* Grain: 500t/hr

* Cement: 400t/hr

– Frozen fish: 100t/hr

– LPG: 300m³/hr

Ship to Ship Transfer

1. Designated STS Area:

– Coordinates: 38°55’N 141°35’E

– Minimum safety distance: 50m from other vessels

– Maximum wave height: 1.5m

– Required documents:

* STS Plan (approved by ClassNK)

* Risk Assessment

* MLIT Notification Form STS-01

2. Equipment Requirements:

– Fenders: Minimum 4 large pneumatic fenders

– Mooring: Minimum 8 lines (4 head, 4 stern)

– Communication: Dedicated VHF channel (Ch.08)

Cargo Gear

1. General Provisions:

– Shore gear available at all commercial berths

– Ships may use own gear at fishing wharves

– Certification requirements:

* Annual load testing

* SWL clearly marked

2. Heavy Lift Capacity:

– Maximum shore-based: 150t (72hr notice required)

– Floating crane: 250t (available on charter)

Shore Cranes

1. Container Terminal:

– 2 post-Panamax ship-to-shore cranes:

* SWL: 50t under spreader

* Outreach: 45m (22 rows)

* Hoist speed: 90m/min

2. General Cargo:

– 3 mobile harbor cranes:

* SWL: 25t @ 20m

* Boom length: 32m

* Power: 300kW diesel-electric

Floating Cranes

1. Available Equipment:

– “Kesennuma No.1” floating crane:

* Capacity: 250t (main hook)

* Auxiliary: 50t

* Dimensions: 40m LOA, 20m beam

2. Operational Details:

– Daily rate: ¥2,500,000 (8hr shift)

– Minimum charter: 4 hours

– Advance notice: 72 hours required

Hoses

1. Oil Transfer Hoses:

– Standard sizes: 8″ and 10″

– Pressure rating: 150psi working

– Testing: Annual hydrostatic test to 225psi

– Connection: ANSI 150# flanges

2. Specialized Hoses:

– LPG: 4″ stainless steel, vacuum jacketed

– Chemical: PTFE lined (6″ diameter)

Specialised Cargo Operation

1. Dangerous Goods:

– IMDG classes accepted: 3,4,5,6,8,9

– Storage:

* Class 3: 2,000m² (fireproof)

* Class 8: 1,000m² (corrosion-resistant)

2. Temperature Controlled:

– Reefer facilities: 200 plugs (-25°C to +25°C)

– Monitoring: Automated alarm system

Lightering and Lighterage

1. Available Services:

– Maximum transfer quantity: 5,000t

– Rate: ¥15,000/ton (minimum 1,000t)

– Equipment:

* 4 barges (1,000t capacity each)

* 2 tugboats (3,000hp)

Barge

1. Available Fleet:

– 10 flat-top barges:

* Dimensions: 30m x 10m

* Capacity: 500t

* Deck strength: 5t/m²

2. Operational Details:

– Hourly rate: ¥50,000 (minimum 4 hours)

– Crew: 2 personnel per barge

Cargo Lashing

1. Standard Practice:

– Performed by licensed stevedores

– Rate: ¥5,000/container

– Materials:

* Twist locks (ISO standard)

* Lashing rods (10t SWL)

2. Alternative Options:

– Crew may perform lashing under supervision

– Requires port approval 24hr in advance

Cleaning Procedures

1. Hold Cleaning:

– Rate: ¥200,000/hold (standard size)

– Water supply: 50m³/hr @ 10bar

– Waste disposal: Licensed contractor required

2. Special Requirements:

– Grain holds: FDA standards

– Chemical tanks: COW procedures

Opening/Closing Hatches

1. Standard Practice:

– Normally by stevedores (included in handling rate)

– Crew operation requires:

* Port permission

* Safety briefing

* Standby stevedore

Delay

1. Typical Scenarios:

– Weather: 6-12 hour delays in winter

– Congestion: Average 8hr wait in peak season

– Documentation: 2-4hr clearance processing

Stevedore Companies

1. Primary Contractor:

– Kesennuma Stevedoring Co., Ltd.

– ETA notice: 72 hours for full gang

– Gang composition:

* Foreman: 1

* Crane operators: 2

* Dockworkers: 12-15

2. Performance Metrics:

– Average productivity: 25 containers/hr

– Incident rate: 0.8/1,000 moves

Working Hours

1. Standard Schedule:

– Day shift: 0800-1700 (Mon-Sat)

– Night shift: 1800-0600 (by arrangement)

2. Overtime Rates:

– Weekdays: 1.5x base rate

– Sundays/holidays: 2.0x base rate

– Minimum call: 4 hours

Warehouses and Yards

1. Storage Facilities:

– Covered warehouses: 25,000m²

* Height: 8m clear

* Floor load: 5t/m²

2. Open Storage:

– Paved yards: 50,000m²

– Security: 24/7 patrols + CCTV

3. Specialized Storage:

– Cold storage: 5,000m³ (-25°C to +15°C)

– Dangerous goods: 3,000m² (Class 3/8)

7.Port Services

General Information

Kesennuma Port provides comprehensive services compliant with:

– Japan Port Service Standards (MLIT Ordinance No.28)

– ISPS Code requirements

– ILO Maritime Labour Convention

– Port Facility Security Plan (PFSP) approved by JCG

– ISO 28000:2007 Security Management System certified

Operational highlights:

– Service hours: 24/7 with prior arrangement

– Emergency response time: <15 minutes

- Language support: Japanese/English available

Bunkering

1. Availability:

– Available at North Oil Terminal (Berths T1/T2)

– Licensed suppliers:

* Nippon Oil Corporation (primary)

* Idemitsu Kosan (alternate)

2. Fuel Specifications:

– IFO 180: Max 3.5% sulfur

– IFO 380: Max 0.5% sulfur (compliant with MARPOL Annex VI)

– MGO: DMA grade, sulfur <0.1%

3. Operational Details:

- Minimum order: 50mt

- Maximum single delivery: 3,000mt

- Barge capacity: 5,000DWT

- Sampling: Joint sampling mandatory

- Documentation: BDN in triplicate (MLIT Form B-7)

4. Lead Times:

- Routine delivery: 48 hours notice

- Emergency supply: 12 hours (surcharge 30%)

Lubricants

1. Available Products:

– Engine oils:

* Cylinder oil: 5070

* System oil: 3008

– Greases:

* Alvania RLQ2

* Rykon No.2

– Hydraulic oils:

* Tellus S2 V 32

* Tellus S2 V 68

2. Supply Chain:

– Primary supplier: JXTG Nippon Oil & Energy

– Minimum order: 20 drums

– Delivery time: 24-48 hours

Fresh Water

1. Technical Specifications:

– Quality: Meets WHO drinking standards

– Chlorination: 0.2-0.5ppm residual

– Testing: Daily bacteriological tests

2. Supply Options:

– Pipeline connection:

* Diameter: 100mm

* Pressure: 3.5bar

– Tanker delivery:

* Capacity: 200m³

* Rate: 50m³/hr

3. Cost Structure:

– Base rate: ¥500/m³

– Connection fee: ¥20,000 (one-time)

– After-hours surcharge: 20%

Stores and Spare Parts

1. Delivery Protocols:

– Truck access:

* Allowed at all berths

* Security screening required

– Barge operations:

* Permitted 0600-1800

* Safety net mandatory

2. Customs Procedures:

– Clearance time: 2-4 hours

– Required documents:

* Inventory list (3 copies)

* Value declaration

– Prohibited items:

* Narcotics (Opium Control Law)

* Firearms (Swords and Firearms Law)

3. Technical Stores:

– Engine parts: Limited local stock

– Electrical components: 48hr lead time

– Safety equipment: CE/JIS certified only

Dunning and Dunnage

1. Material Specifications:

– Softwood dunnage:

* Size: 100x100mm

* Length: 2.4m standard

– Plastic dunnage:

* HDPE material

* Various sizes available

2. Operational Procedures:

– Stevedore handling:

* Included in cargo fees

* Waste removal service

– Crew participation:

* Permitted with PPE

* Limited to ship’s gear

Ship Chandlers

1. Licensed Providers:

1.1 Kesennuma Marine Supplies Co. Ltd.

– Services:

* Fresh provisions (JAS certified)

* Bonded stores (customs cleared)

* Technical supplies

– Delivery fleet:

* 3 trucks (5t capacity)

* 2 launch boats

1.2 Tohoku Ship Services

– Specialty items:

* Refrigerated stores

* Medical supplies

– Payment terms:

* Cash (JPY)

* Letter of credit

Ship Husbandry

1. Available Services:

– Hull cleaning:

* Brush cleaning

* Ultra-high pressure wash

– Tank cleaning:

* Crude oil tanks (COT)

* Chemical tanks

– Painting:

* Brush/roller

* Airless spray

2. Service Providers:

– Sanriku Marine Services

– Crew: 10 certified technicians

– Equipment:

* 400bar pressure washer

* Confined space entry certified

Maintenance and Repairs

1. Deck Department:

– Steelwork repairs (limited)

– Valve overhaul

– Pipework patching

2. Engine Department:

– Pump repairs

– Heat exchanger cleaning

– Electrical motor servicing

3. Certification Requirements:

– All work under PMS approval

– Class surveyor attendance for critical systems

Gangway and Deck Watchmen

1. Security Services:

– Licensed providers: Kesennuma Port Security Co.

– Watchmen qualifications:

* JCG-approved training

* First aid certified

* ISPS awareness training

2. Service Details:

– Standard shift: 8 hours (¥5,000/hour)

– Minimum deployment: 2 watchmen

– Equipment provided:

* Night vision gear

* UHF radios

* First aid kits

Deratting

1. Service Providers:

– JCG-approved exterminators: 2 companies

– Treatment methods:

* Fumigation (methyl bromide)

* Trapping (non-chemical)

2. Certification Process:

– Inspection: 2 hours duration

– Certificate: JCG Form D-8

– Validity: 6 months (global acceptance)

Surveying

1. Classification Society Representatives:

– ClassNK: Full-time surveyor

– ABS/LR: Part-time availability

– Survey response time: 24-48 hours

2. Specialized Surveys:

– Cargo damage assessments

– Bunker surveys (ISO 13739 compliant)

– On-hire/off-hire inspections

Fumigation

1. Agricultural Cargo Treatment:

– Approved chemicals:

* Phosphine tablets

* Magnesium phosphide

– Aeration period: 24 hours minimum

– Safety zone: 50m radius

2. Cost Structure:

– Standard treatment: ¥200,000/hold

– Emergency service: +50% surcharge

– Monitoring: ¥10,000/hour (minimum 8hr)

Crewing and Repatriations

1. Immigration Procedures:

– Processing time: 4-6 hours

– Required documents:

* Passport (6mo validity)

* CDC (original)

* Company guarantee letter

2. Crew Change Facilities:

– Designated area: Port Administration Building

– Transportation:

* Taxi service available

* Shuttle to Sendai Airport

Dry Docks

– Not Available in port limits

– Nearest facilities:

* Sendai Shipyard (80nm): 30,000DWT capacity

* Onahama Dry Dock (120nm): Panamax size

Launch Service

1. Passenger Transfer:

– Operator: Kesennuma Water Taxi

– Vessels:

* 2 aluminum-hull launches

* 12 pax capacity each

– Safety equipment:

* SOLAS-approved lifejackets

* Marine radios

2. Operational Parameters:

– Wave height limit: 1.2m

– Night operations: Restricted

– Transfer time: 15-30 minutes

Certificates Issuing

1. Port Documentation:

– Port Clearance Certificate

– Stores Declaration

– Garbage Record Book endorsement

2. Limitations:

– No classification certificates issued

– No statutory certification services

Shore Electricity

1. Technical Specifications:

– Voltage: 440V ±10%

– Frequency: 60Hz

– Connection: IEC 60092-201 standard

– Maximum load: 1.5MW per vessel

2. Connection Procedure:

– Advance notice: 24 hours

– Safety check required

– Cable handling by port electricians

Phones Services

1. Telecommunications:

– Mobile providers:

* NTT Docomo

* SoftBank

* au by KDDI

– SIM card registration:

* Passport required

* 72-hour activation

2. Rental Services:

– Satellite phones available

– Data packages:

* 1GB: ¥3,000

* 3GB: ¥7,000

Banks

1. Financial Services:

– Kesennuma Shinkin Bank:

* Currency exchange

* Wire transfers

* Notary services

– Operating hours: 0900-1500 (Mon-Fri)

2. ATM Availability:

– Port administration building: 24/7

– Accepts major international cards

Consuls and Visa

– No resident consular officers

– Emergency contacts:

* MOFA hotline: +81-3-3580-3311

* Immigration Bureau: +81-22-398-9147

Mail

1. Postal Services:

– Kesennuma Central Post Office:

* EMS to Asia: ¥1,800 (1kg)

* Surface mail: ¥800 (letter)

– Customs declaration required for parcels

Shore Leave

1. Crew Access:

– Allowed with:

* Valid passport

* Crew ID card

* Port pass issued

– Curfew: 2300-0500 strictly enforced

Medical and Ambulance

1. Healthcare Facilities:

– Port Clinic:

* Doctor on call 24/7

* Basic emergency care

– Kesennuma City Hospital:

* 3km from port

* Hyperbaric chamber available

2. Emergency Contacts:

– Port first aid:

– Ambulance: 119 (Japanese operators)

Seaman’s Clubs

– Not Available within port area

– Alternative facilities in Sendai (2hr by train)

Miscellaneous

1. Special Notices:

– Fishing restrictions:

* No fishing within 500m of berths

* No discharge of bait

– Environmental:

* Strict garbage segregation

* Zero discharge policy

– Navigation:

* Speed limit: 5 knots in basin

* No wash zone enforced