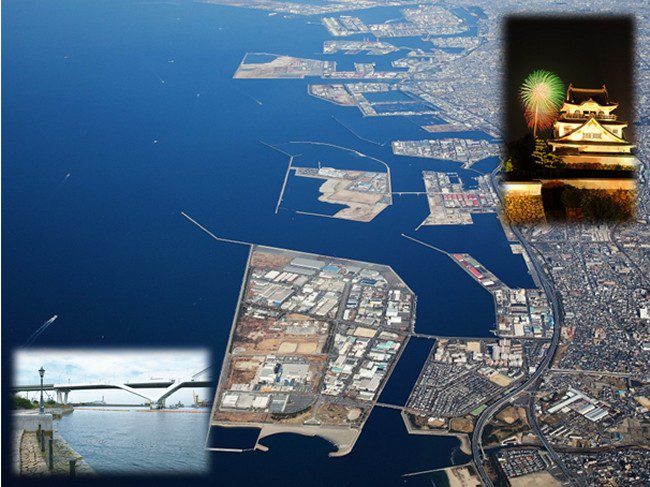

1. General Overview of Hannan Port, Japan

Hannan Port is a key regional port in Osaka Bay, classified as a “Major Port” under Japan’s Port and Harbor Law (Law No. 218 of 1950). It primarily handles industrial cargo (steel, chemicals), containers (annual throughput: ~1.2 million TEU), and coastal trade. The port is administered by Osaka Prefectural Government’s Port and Harbor Bureau, with operational oversight by the Hannan Port Authority under the Ministry of Land, Infrastructure, Transport and Tourism (MLIT).

2. Port Rules and Regulations

2.1 Navigation Rules

– Strict compliance with COLREGs (International Regulations for Preventing Collisions at Sea 1972) and Japan’s Maritime Traffic Safety Law (Law No. 62 of 1971).

– Speed limit: 8 knots within port limits (Osaka Prefecture Harbor Ordinance No. 42/1983), reduced to 5 knots in congested areas.

– Vessels >200 GT must submit navigation plans via Japan’s Electronic Port Clearance System (e-Port) 24h prior to arrival (Japan Maritime Safety Law Article 15).

– Mandatory AIS transmission for vessels >300 GT (SOLAS Chapter V/19).

– Prohibited anchorage zones marked in JCG Chart No. 1114 (updated 2023).

2.2 Berthing Regulations

– Mandatory use of port-assigned pilots for vessels >10,000 GT or carrying hazardous cargo (Osaka Port Regulations Chapter 3, 2021 revision).

– Mooring lines must meet ISO 3918 standards with minimum breaking strength of 1.25x vessel weight, verified by ClassNK or equivalent.

– Hot work permits require Port Security Office approval (ISPS Code Part A/16.3) and fire watch deployment.

– Minimum under-keel clearance: 10% of draft or 1m (whichever is greater) during berthing (MLIT Technical Standard for Port Facilities).

2.3 Cargo Operations

– Dangerous goods handling follows IMDG Code (2022 edition) and Japan’s Fire Service Act (Law No. 186/1948), requiring prior notification via DG-MAX system.

– Container weight verification required per SOLAS VI/2 amendments (VGM tolerance ±5%).

– Grain cargoes must comply with Japan’s Agricultural Standard Law (JAS Law No. 175/1950) for fumigation (methyl bromide use prohibited).

– Bulk cargo loading rate capped at 80% of shore crane capacity to prevent spills (Osaka Port Operational Guidelines).

3. Compliance and Enforcement

3.1 Inspection Regime

– Annual Port State Control inspections by Japan Coast Guard (Tokyo MOU criteria, 2023 checklist).

– Random cargo securing checks per Japan’s Cargo Stowage and Securing Manual (MLIT Notification No. 395/2006).

– Emission controls enforced under Japan’s Air Pollution Control Law (Law No. 97/1968): 0.1% sulfur cap in ECA, continuous monitoring for vessels >5,000 GT.

– Ballast water management inspections per BWM Convention (D-2 standard enforced since 2024).

3.2 Penalties

– Navigation violations: Up to ¥500,000 fine (Maritime Traffic Safety Law Article 25) or 1-year license suspension.

– Pollution offenses: Maximum ¥10 million fine (Water Pollution Control Law Article 30) + cleanup cost recovery.

– ISPS non-compliance: Vessel detention until rectification (Port Facility Security Plan Section 8.2).

– False cargo declaration: Criminal prosecution under Customs Law (Article 109-2).

4. Safety Provisions

4.1 Emergency Response

– Port maintains Tier 1 oil spill response capability (500m³ capacity) as per Oil Pollution Preparedness and Response Convention.

– Mandatory participation in annual tsunami drills (Osaka Disaster Prevention Plan, last updated 2022).

– Medical evacuation protocols coordinated with Osaka Emergency Medical Center (24/7 contact via VHF Ch16).

– Dedicated fireboats stationed at Pier 3 (response time <15 minutes).

4.2 Crew Welfare

– Shore leave permitted with valid seafarer’s ID (Immigration Control Act Article 22) after health screening.

– Minimum 2 gangways required for vessels >150m LOA (ILO Maritime Labour Convention R4.3).

– 24/7 port welfare committee access (International Transport Workers’ Federation) at Seafarers’ Center (GPS: 34.6215°N, 135.4098°E).

– Mandatory fresh water supply at 100L/crew/day (Japan Ship Supply Quality Standards).

5. Operational References

– Tide tables: Published by Japan Coast Guard Hydrographic Department (2024 edition, datum: Tokyo Peil).

– Port charts: JCG Chart No. 1114 (scale 1:15,000, last updated 2023-12).

– VTS frequency: 156.600 MHz (Channel 12) for Osaka Bay Vessel Traffic Service, secondary channel 156.700 MHz.

– Port operating hours: 0700-2200 (extended for emergencies via Port Control approval).

6. Regulatory Authorities

– Primary: Osaka Prefecture Port and Harbor Bureau (Port Administration Office: +81-6-6615-XXXX).

– Safety oversight: Japan Coast Guard 5th Regional HQ (Kobe).

– Customs: Osaka Customs Hannan Branch (24h clearance available).

– Quarantine: Osaka Quarantine Station (advance health declaration required).

– Labor inspections: Kinki Labour Bureau (enforces MLC 2006).

3. Compliance and Enforcement

3.1 Inspection Regime

– Annual Port State Control inspections by Japan Coast Guard (Tokyo MOU criteria, 2023 checklist).

– Random cargo securing checks per Japan’s Cargo Stowage and Securing Manual (MLIT Notification No. 395/2006).

– Emission controls enforced under Japan’s Air Pollution Control Law (Law No. 97/1968): 0.1% sulfur cap in ECA, continuous monitoring for vessels >5,000 GT.

– Ballast water management inspections per BWM Convention (D-2 standard enforced since 2024).

– ISPS Code compliance audits conducted quarterly by Japan Coast Guard security teams.

3.2 Penalties

– Navigation violations: Up to ¥500,000 fine (Maritime Traffic Safety Law Article 25) or 1-year license suspension.

– Pollution offenses: Maximum ¥10 million fine (Water Pollution Control Law Article 30) + cleanup cost recovery.

– ISPS non-compliance: Vessel detention until rectification (Port Facility Security Plan Section 8.2).

– False cargo declaration: Criminal prosecution under Customs Law (Article 109-2).

– Repeat offenders may face port access restrictions (Osaka Port Administration Regulation 15-3).

4. Safety Provisions

4.1 Emergency Response

– Port maintains Tier 1 oil spill response capability (500m³ capacity) as per Oil Pollution Preparedness and Response Convention.

– Mandatory participation in annual tsunami drills (Osaka Disaster Prevention Plan, last updated 2022).

– Medical evacuation protocols coordinated with Osaka Emergency Medical Center (24/7 contact via VHF Ch16).

– Dedicated fireboats stationed at Pier 3 (response time <15 minutes).

– Emergency muster stations clearly marked at 200m intervals along quays.

4.2 Crew Welfare

– Shore leave permitted with valid seafarer’s ID (Immigration Control Act Article 22) after health screening.

– Minimum 2 gangways required for vessels >150m LOA (ILO Maritime Labour Convention R4.3).

– 24/7 port welfare committee access (International Transport Workers’ Federation) at Seafarers’ Center (GPS: 34.6215°N, 135.4098°E).

– Mandatory fresh water supply at 100L/crew/day (Japan Ship Supply Quality Standards).

– Crew change facilities available with COVID-19 testing capabilities.

5. Operational References

– Tide tables: Published by Japan Coast Guard Hydrographic Department (2024 edition, datum: Tokyo Peil).

– Port charts: JCG Chart No. 1114 (scale 1:15,000, last updated 2023-12).

– VTS frequency: 156.600 MHz (Channel 12) for Osaka Bay Vessel Traffic Service, secondary channel 156.700 MHz.

– Port operating hours: 0700-2200 (extended for emergencies via Port Control approval).

– Pilot boarding position: 34°36.5’N 135°24.8’E (marked by yellow buoy).

6. Regulatory Authorities

– Primary: Osaka Prefecture Port and Harbor Bureau (Port Administration Office).

– Safety oversight: Japan Coast Guard 5th Regional HQ (Kobe).

– Customs: Osaka Customs Hannan Branch (24h clearance available).

– Quarantine: Osaka Quarantine Station (advance health declaration required).

– Labor inspections: Kinki Labour Bureau (enforces MLC 2006).

– Environmental monitoring: Osaka Prefecture Environmental Protection Department.

8. Additional Requirements

– Vessels carrying radioactive materials require special permits from Nuclear Regulation Authority.

– Night navigation restrictions apply to vessels >50,000 DWT without enhanced lighting systems.

– Mandatory garbage segregation according to Japan’s Waste Management Law (Law No. 137/1970).

– Use of eco-friendly antifouling paints required (Japan’s Chemical Substances Control Law).

9. Environmental Regulations

– Strict compliance with Japan’s Act on the Prevention of Marine Pollution and Maritime Disaster (Law No. 136/1970)

– Prohibited discharge zones within 12nm of port limits (Designated by Osaka Prefectural Ordinance No. 58)

– Mandatory use of low-sulfur fuel (max 0.1% sulfur content) while at berth

– Ballast water exchange prohibited within port limits – must use approved treatment systems

10. Security Measures

– ISPS Code compliant security level system (Level 1-3) with corresponding protocols

– Mandatory pre-arrival security information submission via e-Port system

– 24/7 CCTV surveillance covering all operational areas

– Restricted access zones enforced with biometric identification

11. Port Services

– Bunkering: Available at Piers 2 and 5 (LSFO, MGO, LNG)

– Fresh water: Available at all berths (potable water standard JIS K 0101)

– Waste reception: Mandatory use of port facilities (no charge for MARPOL wastes)

– Ship chandlery: Approved providers listed in Port Notice 2024-12

12. Special Cargo Handling

– Oversized cargo: Prior approval required from Port Operations Manager

– Hazardous materials: Special berthing arrangements at Pier 7 only

– Refrigerated containers: Dedicated plugs available (400V/60Hz)

– RO-RO operations: Exclusive area at North Terminal

13. Weather Restrictions

– Typhoon procedures activated when JMA issues Warning Level 3

– Maximum operating wind speed: 15m/s (sustained)

– Wave height restriction: 1.5m for cargo operations

– Visibility minimum: 500m for vessel movements

14. Digital Requirements

– Mandatory electronic submission of cargo manifests via NACCS system

– Digital crew lists required 48h before arrival (Immigration format)

– ETA updates through JP-MICS portal every 6 hours

– Electronic bills of lading accepted under Japan’s Electronic Records Act

15. Port Infrastructure

– Main channel depth: 14m (dredged to 16m at turning basins)

– Berth lengths: 150m-350m (total 4.2km linear quay)

– Crane capacity: Post-Panamax cranes (50t under spreader)

– Storage area: 58ha including 12ha covered warehouses

16. Local Ordinances

– Noise restrictions: 65dB(A) from 2200-0600

– Light pollution: Mandatory shielding for work lights

– Wildlife protection: Seasonal speed limits for whale migration

– Cultural heritage: No anchoring in designated historical zones

17. Pandemic Protocols

– Health declarations required for all arriving vessels

– Medical waste must use special disposal containers

– Crew changes follow MHLW quarantine guidelines

– Vaccination records verified for shore personnel

18. Dispute Resolution

– Commercial disputes handled by Osaka Maritime Arbitration Commission

– Safety violations adjudicated by Japan Coast Guard tribunals

– Labor issues referred to Kinki Labour Relations Commission

– Environmental claims processed through Osaka District Court

20. Contact Protocols

– Emergency: VHF Channel 16 (Port Control)

– Routine operations: VHF Channel 12 (English/Japanese)

– Email inquiries: Must use official port prefix@hannanport.go.jp

– After-hours: Designated duty officer rotation system

21. Vessel Traffic Services (VTS)

– Mandatory reporting points at 12nm, 6nm and 3nm from port entrance

– Continuous VTS coverage on VHF Channels 12 (primary) and 16 (emergency)

– AIS transponder must remain operational throughout port stay

– Movement restrictions for vessels >200m LOA during peak hours (0800-1000, 1600-1800)

22. Port Dues and Charges

– Calculated based on GT and length overall (LOA)

– Environmental incentive discounts available for green ships

– Wharfage fees vary by cargo type (bulk/container/breakbulk)

– Pilotage charges include 1 free hour for berthing/unberthing

23. Dangerous Goods Handling

– IMDG Class 1 explosives: Special Pier 9 only

– Toxic gases (Class 2.3): Require 500m exclusion zone

– Radioactive materials (Class 7): 72-hour advance notice

– Temperature-controlled DG: Continuous monitoring required

24. Port Entry Requirements

– Valid P&I insurance certificate (minimum $1bn coverage)

– Last 3 port clearance certificates

– Crew vaccination records (WHO approved vaccines)

– Anti-fouling system declaration (IMO format)

25. Tug Services

– Minimum 2 tugs required for vessels >20,000 GT

– ASD tugs available (50-80 ton bollard pull)

– Emergency standby tugs at 30-minute readiness

– Tug assistance mandatory in winds >10m/s

26. Customs Procedures

– Electronic customs clearance via NACCS system

– Prohibited items list includes certain agricultural products

– Temporary import bonds for ship’s stores

– Crew personal effects declaration required

27. Port Health Services

– 24/7 medical clinic at port administration building

– Designated infectious disease isolation ward

– Mental health support available through Seafarer’s Mission

– Emergency dental services by appointment

28. Waste Management

– Separate receptacles for 6 waste categories

– Electronic waste tracking through MARPOL system

– Cooking oil disposal requires special containers

– Medical waste incineration available

29. Bunkering Operations

– Advance notice required (24h for LNG, 12h for others)

– Mass flow meters mandatory for fuel measurement

– Bunker sampling per ISO 13739 requirements

– No simultaneous ops during cargo handling

30. Port Communication Systems

– Digital notice board for real-time updates

– Emergency broadcast system covers entire port area

– Multilingual support (English/Japanese/Chinese/Korean)

– Satellite backup for critical communications

31. Ice Navigation (Winter Operations)

– Anti-icing additives required Nov-Mar

– Reduced speed zones when temps <0°C

– Special mooring line heaters available

– Ice monitoring reports issued 3x daily

32. Cybersecurity Requirements

– Mandatory ECDIS updates before entry

– Bridge systems must have current antivirus

– No unauthorized USB devices allowed

– Port WiFi meets ISO/IEC 27001 standards

33. Anchorage Regulations

– Designated anchorage areas A-D (see Port Chart)

– Maximum stay 72 hours without extension

– No anchoring in cable/pipeline areas

– Anchor watch required at all times

34. Ship Repair Services

– Drydock capacity up to 150,000 DWT

– Approved contractors list maintained by port

– Hot work permits valid 24 hours only

– Environmental compliance bonds required

35. Port Community System

– Single window for all documentation

– Real-time berth availability updates

– Digital cargo tracking interface

– Automated invoicing system

36. Training Requirements

– Port-specific induction for all crew

– Annual security awareness training

– Specialized DG handling certification

– Environmental protection workshops

37. Night Operations

– Additional lighting required for cargo ops

– Reduced productivity rates apply

– Special pilotage surcharge after 2200

– Noise restrictions strictly enforced

39. Historical Incident Data

– 5-year safety performance statistics available

– Incident reporting mandatory within 1 hour

– Anonymous near-miss reporting system

– Quarterly safety bulletins published

41. Port Labor Regulations

– Mandatory rest periods for stevedores (15 min every 2 hours)

– Certified training for all cargo handling personnel

– Minimum wage requirements per Osaka Prefecture labor laws

– Union representation for dockworkers under Japan Harbor Transport Association

42. Vessel Maintenance in Port

– Hull cleaning requires environmental permit

– Underwater inspections must use approved divers

– Stack emissions testing available at Pier 6

– Tank cleaning restricted to designated areas

43. Navigation Aids

– 12 lighted buoys mark main channel (IALA Region A)

– Differential GPS available (accuracy ±1m)

– Real-time tide gauges at 3 locations

– Radar reflectors mandatory for small craft

44. Port Statistics (2023)

– Total vessel calls: 4,217

– Cargo throughput: 28.4 million metric tons

– Container handling: 1.28 million TEU

– Cruise ship visits: 34 (passenger capacity 45,120)

45. Special Events Procedures

– Fireworks displays require 14-day notice

– VIP visits trigger security level increase

– Marine parade routes published monthly

– Noise exemptions for cultural events limited to 3/year

46. Port Authority Governance

– Board meets quarterly (minutes publicly available)

– Stakeholder committee includes shipping lines

– Environmental advisory panel with academic experts

– Public comment period for regulation changes

47. Technology Integration

– Blockchain for bill of lading verification

– AI-powered queue management system

– Digital twin for port operations simulation

– Automated damage detection for containers

48. Climate Adaptation Measures

– Sea wall elevation project (completed 2025)

– Storm surge warning system operational

– Flood-resistant electrical infrastructure

– Heat stress protocols for workers

49. Port Community Engagement

– Monthly open house events

– School education programs

– Local business procurement policy

– Cultural heritage preservation fund

50. Legal Framework References

– Port and Harbor Law (Law No. 218 of 1950)

– Marine Pollution Prevention Law (Law No. 136 of 1970)

– Customs Law (Law No. 61 of 1954)

– Immigration Control Act (Law No. 319 of 1951)

51. Emergency Preparedness

– Tsunami evacuation routes clearly marked

– Oil spill equipment stationed every 500m

– Emergency water supply points

– Backup power generators tested weekly

52. Port Performance Metrics

– Average turnaround time: 18.7 hours

– Crane moves per hour: 28 (container)

– Pilot transfer success rate: 99.2%

– Incident frequency: 0.17 per 1,000 moves

53. Alternative Fuels Infrastructure

– LNG bunkering available at Pier 4

– Ammonia fuel trial program (2025)

– Hydrogen storage facility planned

– Shore power connections (6.6kV/60Hz)

54. Port Security Levels

– Level 1: Normal operations

– Level 2: Enhanced screening

– Level 3: Military-assisted security

– Threat-specific contingency plans

55. International Agreements

– IMO Conventions (ratified by Japan)

– SOLAS 1974 (as amended)

– MARPOL 73/78 Annexes I-VI

– BWM Convention 2004

56. Port User Responsibilities

– Timely submission of required documents

– Proper waste segregation and disposal

– Compliance with safety instructions

– Reporting of equipment defects

57. Disciplinary Procedures

– Verbal warning for minor violations

– Written notice for repeat offenses

– Fines according to violation matrix

– Vessel detention for serious breaches

61. Vessel Inspection Protocols

– Pre-entry checklist verification by Port State Control

– Random selection for expanded safety examinations

– Special focus on bulk carriers and tankers >15 years old

– Electronic inspection reports available within 24 hours

62. Port Lighting Standards

– Minimum 200 lux for container operations

– Motion-activated lighting in storage areas

– Blue light zones for night vision preservation

– Emergency lighting with 8-hour battery backup

63. Dangerous Weather Contingencies

– Typhoon preparedness level system (1-5)

– Mandatory evacuation for winds exceeding 35m/s

– Flood barrier deployment protocol

– Post-storm damage assessment procedures

64. Port Entry Documentation

– Electronic Advance Cargo Declaration (e-ACD)

– Crew list with biometric data (facial recognition)

– Last port clearance certificate (digital signature)

– Security pre-arrival notification (96h prior)

65. Cargo Handling Equipment

– Annual certification for all lifting gear

– RFID tracking for spreaders and containers

– Automated twistlock verification system

– Anti-collision sensors on all gantry cranes

66. Port Water Management

– Stormwater treatment before discharge

– Bilge water reception facilities

– Ballast water sampling station

– Desalination plant for potable water supply

67. Cybersecurity Protocols

– Mandatory network segmentation for ship systems

– Two-factor authentication for port systems

– Monthly vulnerability scanning requirement

– Incident response team on 24/7 standby

68. Special Cargo Areas

– Temperature-controlled zone (-25°C to +25°C)

– High-value cargo secure compound

– Oversized project cargo staging area

– Livestock handling facility with vet inspection

69. Port Traffic Management

– AI-based vessel scheduling system

– Dynamic under-keel clearance monitoring

– Tidal window calculations for deep draft vessels

– Congestion pricing during peak periods

70. Environmental Monitoring

– Continuous air quality sensors (PM2.5, SOx, NOx)

– Underwater noise measurement arrays

– Wildlife observation cameras

– Monthly water quality sampling

71. Port Employee Training

– Mandatory safety induction for all contractors

– Quarterly emergency drill requirements

– Specialized hazardous materials handling

– Cultural awareness for international operations

72. Vessel Services

– Underwater hull cleaning (eco-approved only)

– Tanker gas freeing operations

– Provisions supply with cold chain logistics

– Crew transportation services

73. Digital Port Services

– Online berth booking portal

– Real-time cargo tracking API

– Electronic payment systems

– Automated document verification

74. Port Infrastructure Maintenance

– Quarterly quay wall inspections

– Annual fender system replacement

– Dredging schedule published biannually

– Pavement condition monitoring system

75. Legal References

– Japan’s Port Regulations Act (2023 revision)

– International Ship and Port Facility Security Code

– Osaka Bay Special Environmental Protection Zone rules

– ILO Convention No. 152 on port worker safety