Advanced Polymer Coatings is to supply MarineLine with protective solutions for the cargo tanks of chemical tankers in Turkey, Greece and China

Shipowners, operators and charterers are paying closer attention to which cargo tank coatings they use, according to an executive for a leading marine coatings supplier.

“Operators are now much more aware that when tank coatings go wrong, it can cost millions of dollars per ship to repair, plus disruption and lack of availability,” says Advanced Polymer Coatings (APC) global marine manager Onur Yildirim.

“This is especially the case for charterers who now take a bigger role in selecting tank coatings they can rely on to help them secure long-term agreements with shipowners.”

Under a series of agreements, US-based APC is supplying its MarineLine tank coating systems for chemical tankers under construction or repair at Turkish, Chinese and Greek shipyards.

In the latest deal, APC will supply its MarineLine tank coating to the Dentas shipyard in Turkey.

This will involve two shiprepair projects for Veysel Vardal Shipping covering the 6,800-dwt chemical tankersBarbaros Uluç VardalandBarbaros Hayrettin Vardal. The 12 cargo tanks and two slop tanks of each vessel will be coated.

In further deals with Turkish shipowners, APC will also supply solutions to recoat six tankers for Mrc Mercan Holding and a single tanker for Transal.

To support the contracts, Mr Yildirim says APC will provide heat curing and inspection services in various shipyards. “It is very pleasing to see APC and MarineLine being chosen and trusted to repair and recoat these vessels with a collection of owners and shipyards we know well,” he says, adding “Building long-term relationships with customers is key to our approach.”

“When tank coatings go wrong, it can cost millions of dollars”

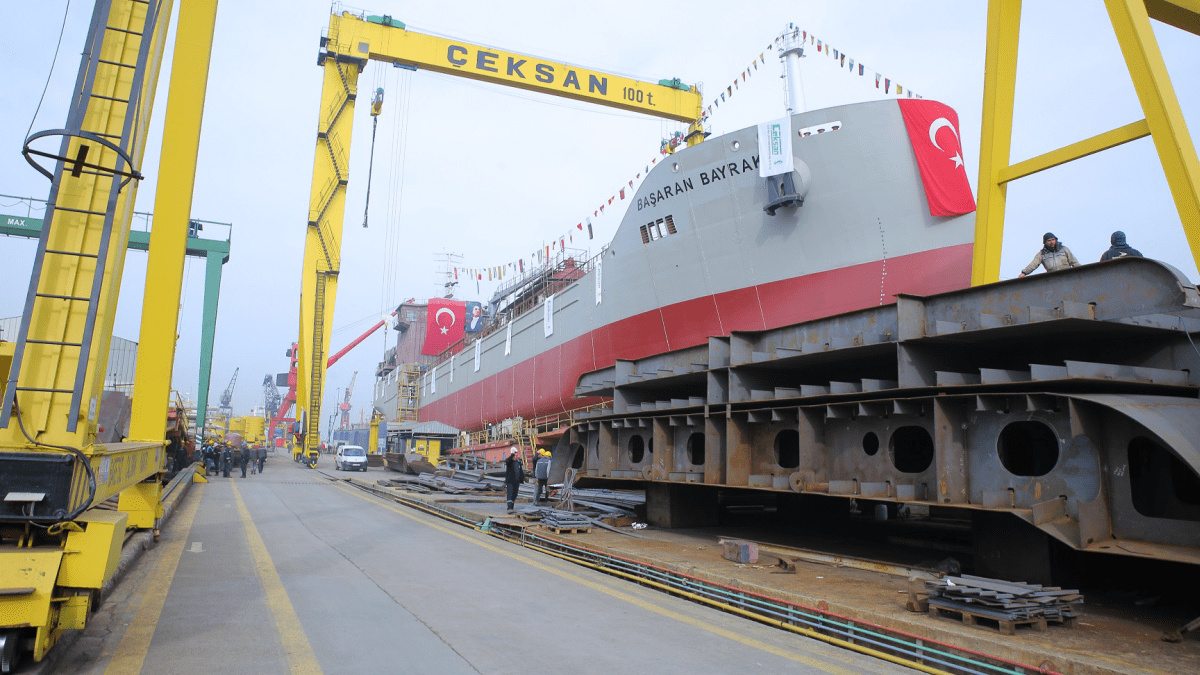

Mr Yildirim says Turkey remains one of APC’s most important export destinations, where it now commands 80% of the market. The latest deals follow a recent contract to recoat 10 tankers for Turkish shipmanager Chemfleet, as well as contracts for an 8,000-dwt /oil tanker newbuild, Basaran Bayrak, under construction at a shipyard in Tuzla, and the 6,000-dwt newbuild tanker Sedat Basak for Atako Shipping and its partner Nakkas Shipping at the Gisan shipyard, also in Tuzla.

APC said it is working on a series of recoat and newbuild jobs in Greece and China.

In July, the coatings supplier inked a deal to supply MarineLine tank coating to the LNG-powered, dual-fuel 6,000-dwt newbuild chemical tankersSir James Fisher and Lady Maria Fisher being built for James Fisher atChina Merchants Jinling Shipyard in Yangzhou. Sir James Fisher will be delivered in Q4 2022.

As this project begins, APC is also starting to apply MarineLine on a fleet of 50,000-dwt MR tankers at China’s New Times Shipbuilding. These vessels are owned by China’s Shandong Shipping and chartered by Shell as part of its Shell Project Solar programme.

MarineLine’s edge is, in Mr Yildrim’s opinion, its ability to carry various chemicals over a sustained period without risk of cross-contamination, even in older vessels.

A high-performance polymer lining system, MarineLine has been applied to the cargo tanks of 700 chemical tankers, representing about 12% of the global fleet, according to APC. Last year saw the Akron, Ohio company coat 56 ships.