New application offers a way for container ships to cut incidents

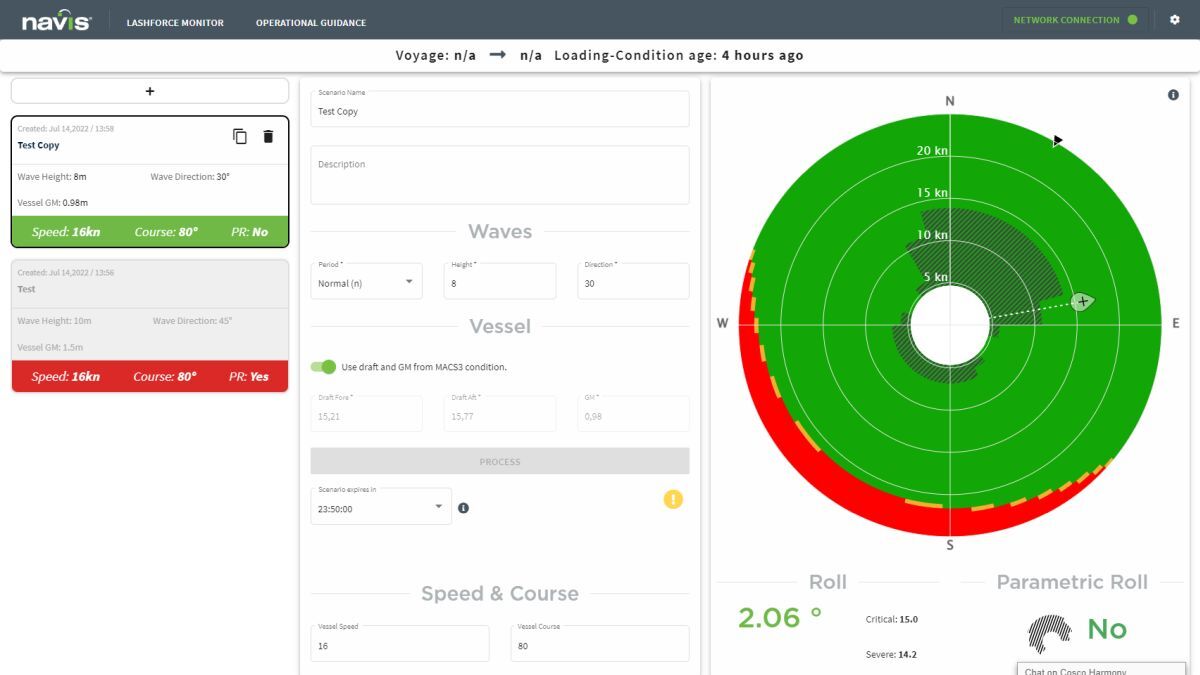

Navis has launched a lashing monitor with operational guidance – based on the actual movement and real loading condition of the vessel – to minimise container incidents.

This add-on application is based on the company’s loading computer MACS3.

Navis product management lead for carrier and vessel solutions, Bastian Gehnke tells Container Shipping & Trade, “We have extended the portfolio around our loading computer to allow the market to further increase safety on board. These new offerings are based on the loading computer but are independent applications.

“The lashing monitor is a tool installed on a vessel so the crew can avoid container losses in heavy seas. We are working together with major class societies; they provide lashing algorithms and operational guidance data of the vessel, and we combine that with our loading computer and onboard installed inclinometer which measures the movement of the vessel.”

The tools consider the actual movement of the vessel while it is sailing and the current loading condition of the vessel on board via the loading computer to calculate the risk of container loss. This stands out in the marketplace because, as Mr Gehnke explains, test loading conditions and theoretical approaches (global climatic models) are usually used to calculate lash forces, rather than real loading conditions and actual movement of the vessels.

“Container vessels are still losing a lot of containers and that shows us the current situation is not sufficient in all conditions at sea,” points out Mr Gehnke.

Navis’ onboard lashing monitor has two purposes: one is monitoring. This measures the motion of the vessel while it is sailing and considers the cargo situation, which is known exactly with the loading computer. A calculation of the lash forces is executed, “Based on your rolling, together with the cargo situation on board we can tell you which areas of stacks are in danger of losing boxes and let the crew know that in the current situation, there are certain stacks in danger”, explains Mr Gehnke.

The second use case is explained by Mr Gehnke, “This is an even more important point. We have an operational guidance module for the crew which shows what measures to take to avoid the risk. Decreasing dangerous situations and getting lash forces down could be done by reducing speed, by changing course or by a combination of both. The operational guidance allows the crew to create different scenarios and simulate them. The crew can make an informed decision on the measures they want to take.”

He sums up, “For the first time, the data from class is coming together with real cargo situations and vessel movements. This is a unique and precise tool for the crew and early adopters using it on board have given very positive feedback.”

As part of its work to minimise the risk of containers getting lost at sea, Navis is also involved in the joint-industry TopTier research project from the Dutch Marin Institute, which is looking at lashing issues by combining theoretical research with real tools.