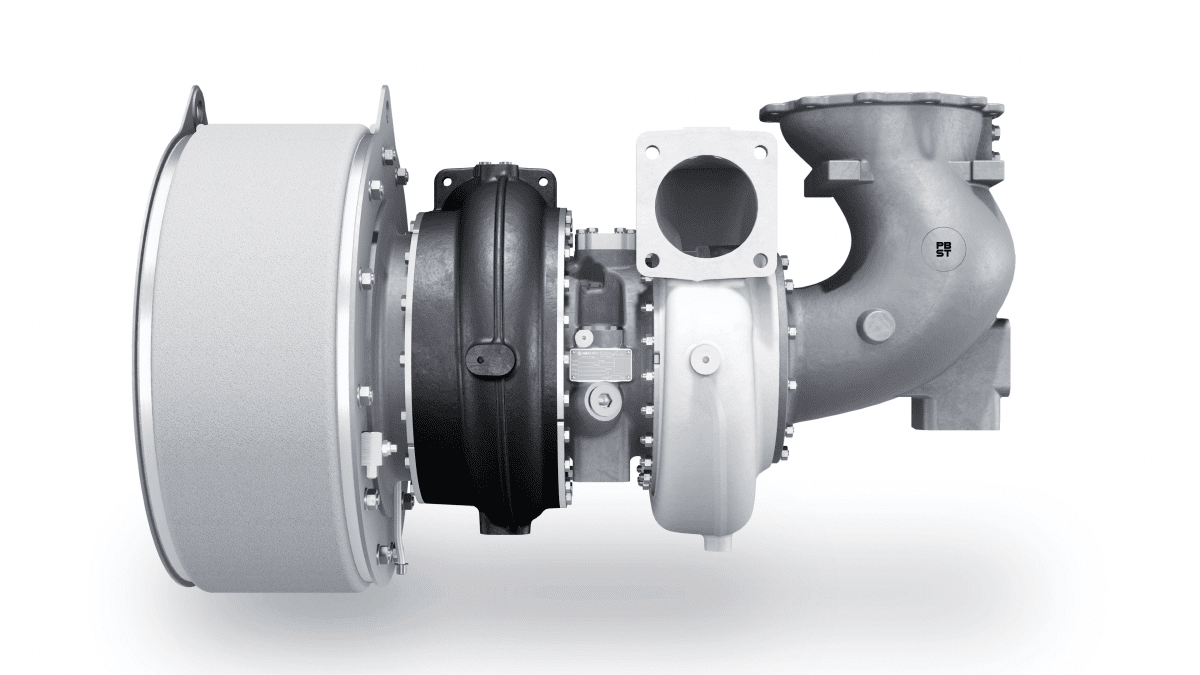

PBST will introduce two new radial turbocharger series in 2022 that are designed for use with gensets and main engines, offering improved power and lower fuel consumption

This year, leading turbocharger designer PBST plans to introduce a new product line of radial turbochargers with pressure ratios of 7 and has boosted the volume flow in another new product. These new turbocharger families are designed for main propulsion and genset engines and use with a wide range of future fuels.

Established through a combination of MAN Turbochargers and PBS Turbo, the Augsburg, Germany-based marine turbocharger manufacturer reports both turbocharger families are based on newly developed technologies, leading to a significant step in product capabilities and use significantly smaller rotors, thereby allowing for a fast dynamic engine response.

The main innovation behind both series is the advanced numerical simulation used for their design, something that was not possible several years ago. Improved numerical methods and steadily rising processor capabilities allow complex simulations to improve flow parts for higher performance.

As part of the development work, both aerodynamic and structural mechanics behaviour was simulated, and a key design consideration was to ensure the highest possible component lifetimes, given the higher pressures and temperatures they are exposed to. The designs were developed based on the numerical research and then tested on the company’s test rig, confirming the positive results.

Current single-stage turbocharger systems achieve pressure ratios of 5 to 6, but the new TCP range significantly increases this pressure ratio to well above 6, and pressure ratios beyond 7 are feasible. PBST reports that it has developed completely new aerodynamic stages for both the compressor side and the turbine side to reach this industry benchmark.

“Fuel consumption in the relevant operation range was reduced by 4.5% with a TCF retrofit”

The new turbochargers use the same connection dimensions as similar turbochargers with lower output and can be exchanged without major adaptions. The increased pressure will allow customers to significantly increase engine power output, and a first application of the technology has achieved power increases of around 20% with only slight engine modifications. This means more power with similar costs, or smaller engines or less cylinders for the same output. In parallel, PBST managed to significantly increase the efficiency of the turbochargers to reduce fuel consumption and emissions from customer engines.

Increased volume flow

The second turbocharger range, TCF, offers significantly increased volume flow. The new range is an expansion and upgrade of the existing TCT range, but with newly optimised flow performance. The technology has been designed to achieve the highest efficiencies at pressure ratios below 5 and is especially well suited to optimising engines for part load. Significant improvements in fuel consumption, especially for gensets, have been demonstrated in studies with first customers.

Due to the turbochargers achieving their highest efficiency gains in part load, and easy exchangeability, they are especially well suited to help shipowners to better comply with future Energy Efficiency Existing Ship Index (EEXI) requirements and reduce emissions of engines already in the field. In one case study, fuel consumption in the relevant operation range was reduced by 4.5% with a TCF retrofit and engine optimisation package. The series is also suited to work as a low-pressure stage turbocharger in two-stage applications.

Modular design

Both new turbocharger series have been designed to be modular in construction, using as many parts in common as possible, although some rotating components and casings will differ between the two families. In this, PBST has leveraged the Volkswagen Group’s expertise in developing modular systems for the car industry.

Designed for future fuels

The new turbochargers are designed for gensets or main propulsion engines and will include models for high-, medium- and low-speed engines, including TCF models for two-stroke engines. To enable for the full decarbonisation of its customers’ portfolio, these turbochargers are designed for operation with a wide range of future fuels, including hydrogen and ammonia. The company notes that its existing ranges are also suitable for use with new fuels on test engines.

PBST feels it is time to implement a new turbocharger series to cope with the upcoming CO2 targets being set all over the world leading up to 2050. It also expects the need for higher efficiencies and the need for higher pressures to get increased power density out of existing engines, as well as equal power density out of the new engines being developed for burning future fuels and is prepared for such a scenario.

“These turbochargers are designed for operation with a wide range of future fuels, including hydrogen and ammonia”

Designers of turbochargers and aftertreatment systems for two- and four-stroke engines, PBST is conducting on-going tests of new-series TCP and TCF turbochargers, and component tests are also well under way. Engine manufacturers are engaged in several projects, and first series hardware will be available for engine tests starting from 2022. Seven frame sizes are currently planned for each series to cover a wide application range of high-, medium- and low-speed engines for marine as well as other mobile applications, including rail and mining, and also stationary power-generation applications. The range will be rolled out in response to customer demand.