Wärtsilä’s newly launched multi-fuel retrofit platform enables the conversion of 2-stroke electronically-controlled marine propulsion engines, currently running on diesel, to operate on either LNG, methanol or ammonia with minimal off-hire time for the vessel.

The development of the concept was recently concluded after successful tests at Wärtsilä’s two-stroke engine laboratory in Trieste. MSC Shipmanagement has collaborated with Wärtsilä throughout the development, and the pilot installation on a 13,000 TEU MSC containership powered by a Wärtsilä 12RT-flex96C is currently in project execution and expected to be ready for LNG by the third quarter of 2023. A subsequent ammonia retrofit on the same technology demonstration vessel, is planned for 2024.

The platform’s medium-pressure combustion technology has the high compression ratio of Diesel cycle without the bulky, expensive fuel supply components, and the simplicity and low energy demand of Otto cycle, without the methane slip (≤0.3 g/kWh).

A world-first feature of the concept is the cryogenic fuel supply system. Cryogenic LNG is supplied directly to the engine at around -150oC and at low pressure, rather than heating it to around 40oC as is done for other engine technologies. This eliminates the need for expensive, energy-demanding and high-maintenance compressors, pumps and heat exchangers and means the footprint of the fuel supply system is minimal, maximising installation flexibility for retrofitting vessels in service. As a further energy efficiency measure, the fuel pressure is amplified to more than 100 bar before injection into the cylinder using servo oil power already available from the engine and jacket cooling water is used to raise the temperature of LNG to expand it to gas.

Up to 800 m3 in onboard space can be saved on fuel gas supply systems on the most power-hungry vessels, with capital investment in them reduced by up to 20% and operating costs also lowered. The multifuel supply system also offers redundancy and operational flexibility and reliability, with the capability of switching to use conventional liquid fuels such as HFO, MDO or VLSFO.

“The hybrid combustion principle applies to all fuels on the platform, but they will demonstrate different thermodynamic behaviours and will require different tuning strategies,” said Sangram Nanda, General Manager 2-Stroke Product Management & Engineering. “We are preparing to run full-scale engine testing on LNG in our 2-stroke laboratory in Trieste in June 2022 thus finalising engine performance development activities for this fuel. We will then shift our focus to methanol with the first tests planned before the end of 2022. Ammonia testing will commence before the end of 2023, with the aim to carry out the adaptation of MSC’s technology demonstration vessel and a first vessel conversion within 2024.”

Retrofit package

The new equipment required for retrofit is skid mounted where possible to expedite installation. To ensure fuel flexibility, storage tanks and piping can be specified to be future-fuel compatible in advance, and a new innovative flexible steel pipe has been incorporated to ensure retrofit is possible even where space is limited.

The modular add-ons include an additional control system for the new cryogenic fuel added adjacent to the engine’s original one, which will continue to control diesel combustion. Cylinder covers have been redesigned and two new injectors added to ensure flame propagation and complete burn of the injected fuel.

“To take full advantage of the inherent modularity of our platform, which allows us to convert the engine from one fuel to the other with minimal effort and investment, we are defining the fuel containment and supply system to be compatible with both LNG and ammonia for the MSC technology demonstration vessel. For commercial conversion projects, it is advisable to consider the requirements for such system compatibility during the project specification phase,” said Nanda.

Operational flexibility

Key benefits of the retrofit include reduced emissions and GHG footprint with negligible fuel slip and overall low energy consumption, long-term CII compliance and extended operational lifetime for the vessel.

Stam Achillas, Head of Business Development & Sales, 2-Stroke Fuel Conversions at Wärtsilä

For a 15,000 TEU containership, conversion to enable the use of LNG can offer around a 20% improvement in Annual Efficiency Ratio (AER). This can be improved further at a later date by adding synthetic or bio-LNG as a drop-in fuel. Wärtsilä’s financial modelling indicates that a vessel that would fall into CII’s D rating in 2023 can keep within the C rating until at least 2030 by using LNG. Adding a blend of 20% bio-LNG would keep the vessel within category A until around 2030.

The improvement in AER could enable a ship operator to keep in the highest available CII rating to, for example, work with charterers demanding high levels of environmental protection. Alternatively, the vessel operator could choose to make use of the gap between maximum compliance and required compliance to operate with greater flexibility – increasing vessel speed for some voyages while remaining within the limits of the CII rating. This could lead to greater utilisation of the vessel and access to charters that require a higher speed. Or the operator could choose to take advantage of differences in fuel prices, for example by adjusting the proportion of bio-LNG used, or running on conventional fuel for some voyages while still staying compliant.

A methanol pathway

As well as the conversion to LNG, the platform enables the switch from diesel directly to methanol or ammonia. “We see a growing interest in methanol conversions, for which we are close to securing the first orders,” says Stam Achillas, Head of Business Development & Sales, 2-Stroke Fuel Conversions. “We anticipate the first methanol conversion project in the second half of 2023. When it comes to ammonia, owners gravitate more towards fuel-readiness options, both as the next step after an LNG or methanol conversion and for newbuilds. Furthermore, stakeholders such as financiers, charterers and fuel suppliers are eager to join the discussion, and it won’t be long before we see innovative financing and business models related to fuel conversions emerging.”

Some bulk carriers could find achieving CII compliance difficult, and the methanol conversion pathway, with lower fuel tank costs, could enable a capsize bulk carrier that would otherwise drop to a D rating by mid-2023 to stay within a C rating until almost 2030 by converting to use first fossil methanol and then adding bio-methanol as a drop-in fuel.

Project management

The multi-fuel retrofit platform is aimed at vessels operating with two-stroke, electronically controlled engines, including both large and smaller bore engine types. Initially Wärtsilä/WinGD branded engines will be targeted, but the technology can be applied, in principle, to any electronically-controlled 2-stroke engine.

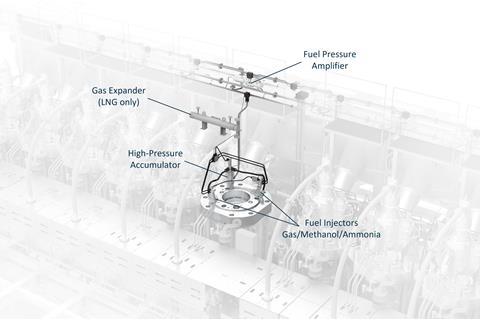

A typical project can take up to a year and a half from initial planning to completion, but off-hire time is minimised with the engine conversion taking approximately three weeks, and a target to complete the vessel fuel conversion within five weeks at a repair yard. The scope of the conversion includes per cylinder: cylinder cover with /gas injectors, high-pressure accumulator, gas evaporator (LNG only) and fuel pressure amplifier. Per engine, it includes: rail box enclosure with ventilation system, engine control system upgrade, instrumentation, sensors, cabinets and cables, safety and monitoring system extension, turbocharger rematching, on-engine piping, on-engine platform conversions and safety spare parts.

Wärtsilä is able to specify and deliver the full spectrum of fuel conversion solutions for merchant ships including fuel gas supply system including LNG tank, 2-stroke main engine conversion, 4-stroke DF or multi-fuel auxiliary engines as a conversion or replacement, boil-off-gas management system and safety systems. The company also offers extended support to customers with its digitally-enabled lifecycle solutions.

For vessels opting for an LNG retrofit, onward conversions to future fuels can be made simpler and more cost effective with planning ahead at the initial LNG retrofit stage. Storage tanks and piping can be specified in advance to ensure compatibility with future fuels, for example. The conversion can also be combined with energy-saving technologies like air lubrication systems, gate rudders or rotor sails to maximise efficiency gains.

Wärtsilä estimates that the engine specific conversion cost for a 14,000 TEU containership with a 12RT-flex96C engine would be approximately EUR4 million. For a 310,000dwt VLCC with a W7X82 engine, the engine conversion cost would be EUR2.9 million, and for a 210,000dwt Newcastlemax bulk carrier with a W6X72 engine it would be EUR2.7 million.

A broader market

Achillas anticipates interest in the platform from newbuilding projects. “Despite the technology options available, owners still struggle with deciding which fuel pathway to choose for their newbuilds, mainly due to the ever-present uncertainties surrounding the availability and pricing of future fuels. A solution to this conundrum may be a generation of truly fuel-ready vessels, designed and built purposely for later fuel conversion. In such a concept, our fuel conversions platform can ensure the two-stroke propulsion engine will be ready for any marine fuel.”