Biofouling companies are developing new technology on the back of the Clean Hull Initiative

Biofouling management is set to get tougher as IMO wants to clamp down on the transfer of invasive aquatic species from a ship’s hull.

The importance of biofouling management was emphasised by Jotun Hull Performance regional category manager Tom H Evensen at Riviera Maritime Media’s New insights on marine biofouling management webinar, held earlier this year.

He explained the biofouling challenge in his presentation: IMO estimates biofouling accounts for the emissions of around 83M tonnes of CO2 and 2M tonnes of other greenhouse gas emissions per year. At US$400 per tonne of fuel, the industry cost of excess fuel is around US$11Bn per year.

He added, “Biofouling also contributes to the transfer of invasive aquatic species, affecting biodiversity and triggering staggering clean-up costs. And forthcoming international regulations (EEXI, CII) will further add to local regulations already in place.”

IMO considers invasive aquatic species a major threat to the world’s oceans and this, said Mr Evensen, is why they have a low fouling partnership alongside Global Environmental Facility and a UN development programme, which will address the build-up of species on underwater hulls. Existing biofouling guidelines are under revision and are expected to minimise the transfer of aquatic species.

Mr Evensen said, “The guidelines’ draft recommends a proactive approach to remove early stages of fouling settlement and if any are detected in inspection, it is recommendedthese are cleaned in drydock, so this could potentially change the landscape.”

Jotun is an initiator of the Clean Hull Initiative–launched at Nor-Shipping this year – that is led by NGO Bellona. This aims to implement an industry standard for proactive hull cleans.

“The focus is on biofouling as an environmental issue and the emergence of proactive hull cleaning technology is a tool to combat this,” explained Mr Evensen. “The desired impact is to have a significant reduction of biofouling on the global fleet and reduce the transfer of invasive marine species on hulls, thus reducing greenhouse gas emissions.”

Mr Evensen’s presentation showed the potential impact of the current business-as-usual approach using actual data from a bulker in a typical trade, which shows multiple cleanings. Its performance loss is a market average 5.9% speed loss. Performance analysis is based on ISO 19030 methodology. “This vessel would require a 17.7% increase in power on average to compensate for the incurred speed loss. The additional cost of underwater hull cleaning and complexity must be taken into consideration,” Mr Evensen explained in his presentation.

Jotun’s response to tackling these challenges is its Hull Skating Solution. Mr Evensen said, “Hull Skating Solution is a fundamentally different approach to what the market does today. We have a proactive unit that stays on vessels and removes the early stages of fouling before a problem develops.”

An algorithm is used to predict the right time for ship operators to proactively clean the hull. Mr Eversen commented, “This leaves owners with an unbeatable environmental footprint and minimal performance loss, with no debris contributing to the transmission of invasive species. It has the best hull performance with full operational flexibility. Hull state verification capabilities are available 24/7.”

Summing up, he explained regulations are “changing at a tremendous pace,” and highlighted regulatory developments that are supporting or recommending proactive cleaning. These include: IMO Biofouling Guidelines (currently under revision); New Zealand Craft Risk Management Standard for Biofouling; Australia Antifouling and inwater cleaning guidelines; USA Vessel Incidental Discharge Act; and Canada Draft voluntary guidance for relevant authorities on inwater cleaning of vessels.

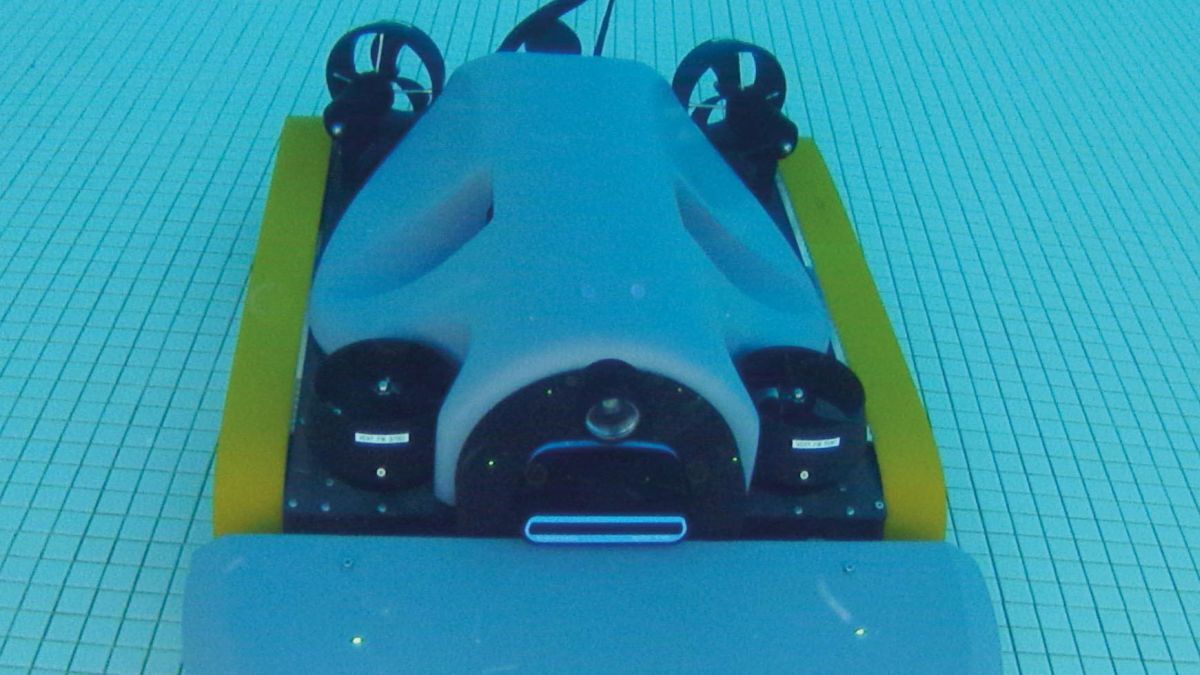

Elsewhere, Armach Robotics is also part of the Clean Hull Initiative and is involved in developing proactive solutions. It has made an agreement with Bellona to work together to facilitate proactive hull cleaning using remotely controlled and autonomous robotics around the world and to reduce the risks of such solutions.

“Biofouling is a global problem, and to solve a global problem we need to collaborate globally,” said Bellona chief executive Hallstein Havåg.

“This collaboration aims to accelerate the uptake of proactive hull cleaning, and to understand the limits and risks with such solutions,” Armach Robotics vice president for growth and strategy Rob Howard added.

“Armach is dedicated to leading the industry with cutting-edge technological solutions for hull efficiency and proactive ship maintenance,” said Mr Howard.

“Our work with Bellona and others is crucial to informing and guiding an industry that is faced with rapid change around ship efficiency in the very near future with EEXI and CII regulations taking effect in 2023.”

Armach has developed and tested an autonomous hull cleaning robot for removing biofouling in ports and at sea. In its latest project, Armach will trial the use of these autonomous units with the US Navy.