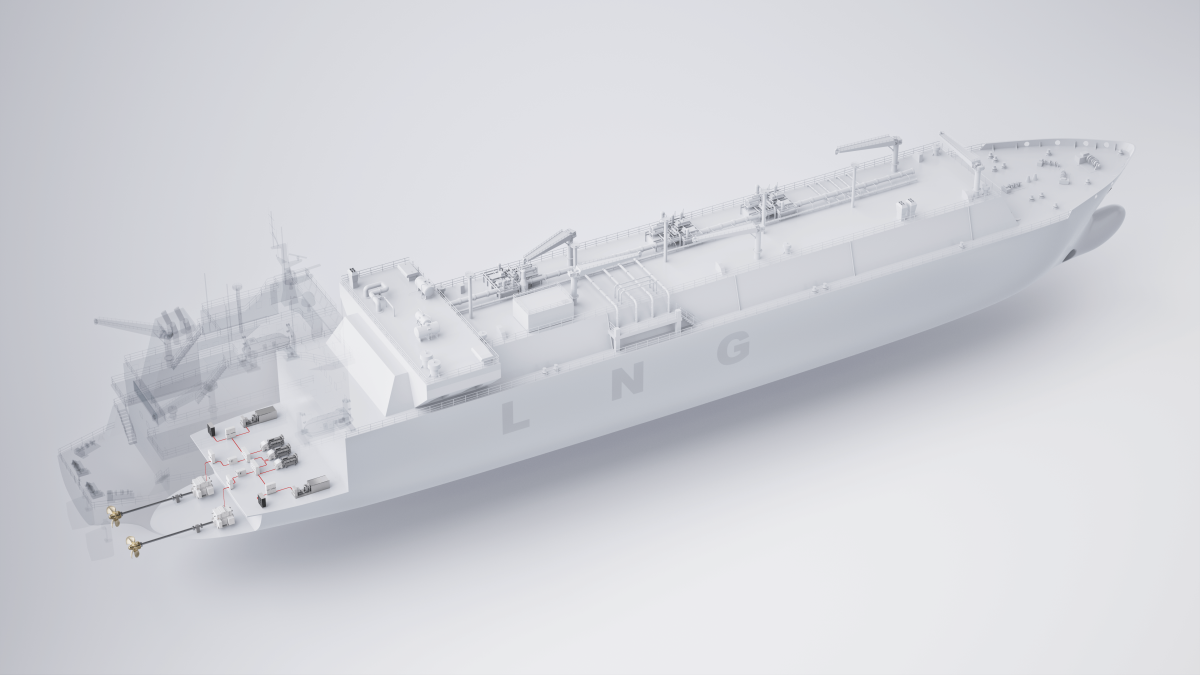

Rendering showing DFE+ dual-fuel diesel-electric propulsion concept for an LNG carrier (source: ABB)

Rendering showing DFE+ dual-fuel diesel-electric propulsion concept for an LNG carrier (source: ABB)

DNV study highlights energy efficiency and potential cargo space gains for LNG carriers from new ABB and MAN DFE+ propulsion solution

A reimagined diesel-electric propulsion concept that uses new four-stroke engine technology offers “a competitive and more energy efficient alternative to even the most efficient conventional dual-fuel LNG carrier propulsion designs,” according to a recent DNV study.

The study verifies the potential energy efficiency and potential cargo gains from the concept, called DFE+, which employs existing components from engine maker MAN Energy Solutions (MAN ES) and marine technology and system integrator, ABB. These components include ABB Dynamic AC controls, batteries, four-stroke, dual-fuel engine technology from MAN ES, permanent magnet motors, predictive emissions monitoring system, and Azipods.

At the heart of DFE+ is MAN ES’s newly introduced fuel-flexible, four-stroke, dual-fuel 49/60DF engine, which can operate on LNG, MDO, MGO and HFO, and biofuels HVO and B40.

Specs on the medium-speed engine include a power output of 1,300 kW at 600 rpm, with a specific fuel consumption of 6,990 kj/kWh at 85% load in gas mode and specific fuel oil consumption of 171 g/kWh at 85% load in diesel mode.

The concept “reimagines” well-proven dual-fuel diesel electric (DFDE) propulsion, which has lost ground in recent years to both two-stroke, high-pressure, dual-fuel and two-stroke, low-pressure, dual-fuel engine technology for LNG carrier newbuilds.

“The time is right to explore next-generation technologies”

According to DNV, the smaller machinery space requirements for DFE+ could deliver “a conservative estimate of 5 percent greater cargo capacity. Combined with other steps to optimise performance, the DFE+ concept could contribute to overall energy savings of 6 – 7.5%, considering the ship’s increased transport work.”

DNV scientific advisor, George Dimopoulos, noted the headwinds LNG shipowners face from the alphabet soup of international maritime air pollution regulations, namely EEXI, EEDI and CII, and limited potential efficiency gains from available propulsion solutions. “The ABB – MAN propulsion concept aims to offer a highly effective way for LNG carriers to meet progressively tightening emissions regulations while also reducing fuel costs,” said Mr Dimopoulos.

ABB Marine & Ports strategic development and vice president, sales, Rune Lysebo, said: “The time is right to explore next-generation technologies [for LNG carriers]. With … emissions regulations continuing to tighten, owners need new technologies to meet the requirements that apply to this specific class of ships.”

DFE+ could be installed with an energy storage solution to operate as a spinning reserve, or come coupled with ABB’s Azipod electric propulsion. ABB and MAN will also explore integrating fuel cells as the technology matures.

As for the four-stroke, dual-fuel MAN 49/60DF engine, MAN ES four-stroke marine sales manager, Thomas Huchatz, noted the engine is optimised for operating on LNG. During a webinar, he said the 49/60DF engine incorporates skip-firing technology to optimise the combustion and reduce “crevices in the combustion chamber where unburnt gas may hide,” helping slash methane slip.“[Skip firing] means that at low engine load, we are not firing all the cylinders, significantly reducing methane emissions,” he pointed out. These evolutionary changes in the engine platform compared to previous generation four-stroke MAN 51/60DF engine technology have resulted in a 50% reduction in methane slip, said Mr Huchatz.