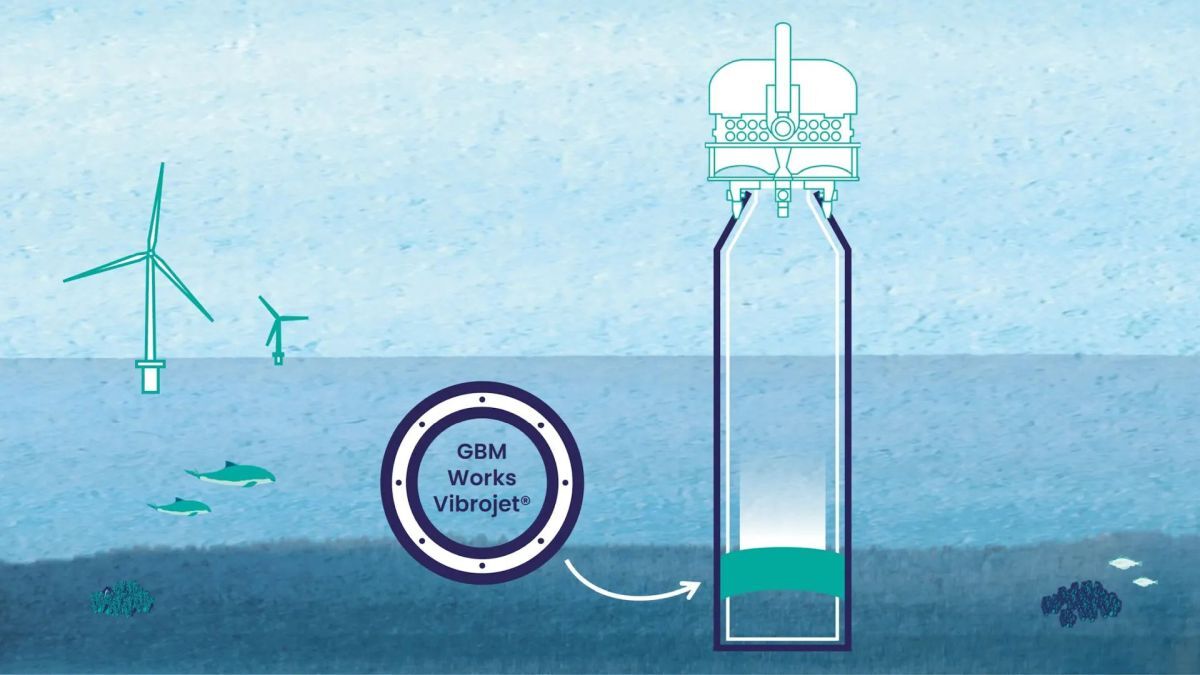

The Vibrojet concept combines vibratory piling with fluidisation of the seabed using jetting (source: GBM Works)

The Vibrojet concept combines vibratory piling with fluidisation of the seabed using jetting (source: GBM Works)

Vibrojet technique combines vibratory piling and fluidisation of the seabed using jetting technology

GBM Works, a spin-off from Delft University of Technology, has been awarded a contract to demonstrate a silent piling technique for monopile foundations on an offshore windfarm in the Netherlands.

The company has been developing the Vibrojet piling technique for some time and is part of the SIMPLE III project that secured funding from the RVO, the Netherlands Enterprise Agency in 2023.

Data obtained from the SIMPLE III project – which is being undertaken with partners including Atlantic Shores, CAPE Holland, Deltares, DEME, Ecowende, Eneco, GBM Works, Shell, TNO, Van Oord and Vattenfall – will be used to help take the silent installation technique to technology readiness level 7 and complete the technology qualification process for the concept. Once this process has been completed, Vibrojet will be ready to be applied on a commercial scale. The monopile installation contract was awarded to GBM Works by Ecowende, developer of the Hollandse Kust West Site VI offshore windfarm.

The innovative piling technique is based on the use of vibratory pile driving and GBM Works’ patented jetting technology, which is installed inside a monopile. The combination of vibration and jetting reduces resistance, making installation more efficient and much quieter than conventional pile driving techniques, minimising the impact on marine life.

The new piling technique has several potential advantages and GBM Works believes it can drive piles into the seabed more quickly than conventional techniques and drive them to a greater depth. Doing so means it can help to reduce costs.

Injecting water at the base of a monopile as it is being driven temporarily fluidises the seabed material. This results in a reduction of what is known as inner shaft friction. This in turn makes it easier to vibrate a monopile into the ground.

The process of water injection is two-fold: jetting water loosens the soil inside the pile, then uniformly fluidises it in order to reduce resistance. Vibrating the pile in an axial (up and down) direction reduces outer shaft friction and tip resistance.

Ecowende engineering manager Arnold Reijnders says, “We are very enthusiastic about our collaboration with GBM Works to further develop the Vibrojet system. We hope the project will make an important contribution, making construction of the next generation of offshore windfarms more environmentally friendly.”

GBM Works business development manager Marcelo Werneck describes the Hollandse Kust West project as the company’s “entrance to the offshore installation market.”

He says by installing three monopiles, the value of the Vibrojet technology will be demonstrated. “This will be an important step towards broader application of the technology.”

The scope of the contract includes engineering and manufacturing the jetting system and support during the installation process. To execute the project, GBM Works is also working closely with Ecowende’s partners Van Oord, SIF and Ramboll.

Sign up for Riviera’s series of technical and operational webinars and conferences: