Tidewater is redefining how vessel dry-dockings are managed, estimating up to a 60% reduction in project time after deploying UniSea’s Maindeck digital platform during the recent yard stay of the Highland Prestige at Dales Marine Services in Aberdeen.

According to Chris Tundogan, Assistant Operations Superintendent at Tidewater, the Maindeck app has “revolutionized” the way dry-docking projects are planned and executed, replacing spreadsheet-heavy workflows and scattered communications with a centralized, real-time management tool.

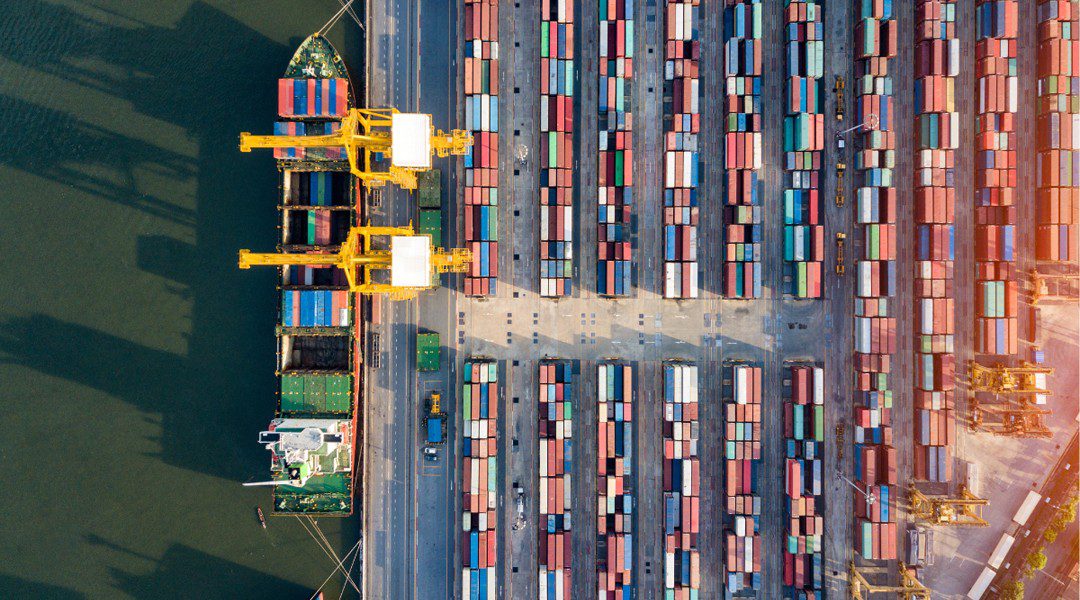

The 2007-built platform supply vessel (PSV) underwent an intermediate survey earlier this year, including hull, anode, propeller, and engine inspections to maintain class compliance before returning to TAQA Bratani decommissioning support operations in the UK North Sea. Traditionally, hundreds of tasks across multiple trades create coordination and reporting challenges. Maindeck’s cloud-based interface—accessible via phone, tablet, or PC—consolidates updates, job tracking, and cost monitoring into one shared platform.

“By consolidating reporting and tracking into one system, the Maindeck app has reduced time-consuming administrative tasks and provided a much more efficient way to manage the workflow,” said Tundogan. “It allows faster, more responsive project management, with real-time visibility on costs and progress.”

For Tidewater, the payoff is straightforward: shorter yard stays, fewer overruns, and quicker vessel reactivation—a tangible bottom-line benefit in an offshore energy market where every day in dock counts.

Tidewater kept track of the dry-docking project through real-time updates by multiple users in the Maindeck app. Photos: /J Dyer Photography