Pacific Basin is deploying XGIT-PROP across 40 vessels (source: GIT)

Pacific Basin is deploying XGIT-PROP across 40 vessels (source: GIT)

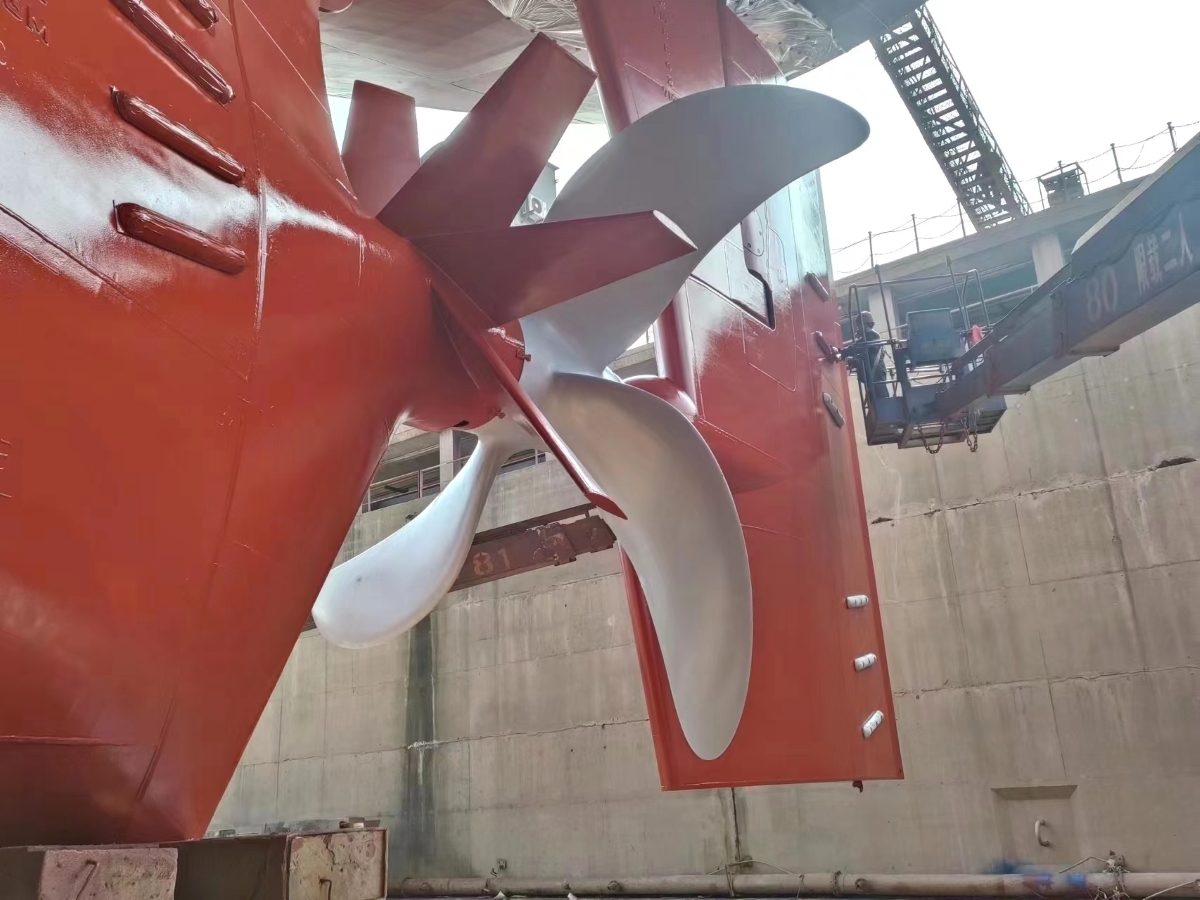

Pacific Basin, a prominent dry bulk shipping company, is taking a proactive approach towards energy efficiency and environmental sustainability by adopting graphene-based propeller coating XGIT-PROP across its entire fleet

Developed by Canadian company GIT Coatings, XGIT-PROP has the potential to boost vessel performance by up to 4%, making it a formidable solution for improving CII and RightShip GHG ratings.

Having witnessed positive outcomes following the application on one of its Supramax dry bulk vessels, Pacific Basin will deploy XGIT-PROP across 40 vessels slated for drydock maintenance in 2024.

This marks the largest implementation of graphene-based propeller coating in the dry bulk sector.

Pacific Basin general manager of optimisation and decarbonisation Sanjay Relan said, “Since 2007, we have employed silicone paint to coat our vessels’ propellers, aiming to maintain a smooth surface and mitigate the need for frequent polishing to restore performance. However, edge damage to the silicone coating have persisted, necessitating complete stripping and reapplication of the propeller coating during each docking.”

He added, “By embracing XGIT-PROP hard coating across our entire fleet, we are proactively embracing more sustainable practices. We anticipate maintaining a damage-free, smooth propeller surface and enhancing efficiency over extended periods. At a fleetwide level, significant reductions in both environmental impact and operational costs are anticipated.”

XGIT-PROP, a biocide-free hard foul release coating, is engineered to endure the rigorous conditions encountered by propellers, addressing the limitations of traditional biocide-based soft foul release coatings prone to releasing silicone oils and peeling from propeller blades.

By combining a robust adhesive primer with a hard foul release topcoat, XGIT-PROP ensures sustained smoothness of the propeller surface throughout the drydocking cycle.

A fuel efficiency study conducted by Stolt Tankers in 2022 confirmed XGIT-PROP’s potential to reduce fuel consumption by up to 4%. Furthermore, shipowners in the dry bulk sector are leveraging XGIT-PROP’s efficiency enhancements to elevate their vessels’ RightShip GHG ratings.

GIT Coatings director of business development Maiko Arras remarked, “Collaborating with Pacific Basin represents a significant milestone in our journey. While we have established fleet supply agreements with numerous shipping companies, Pacific Basin’s comprehensive integration of XGIT-PROP across its dry bulk vessel fleet is unprecedented. We are pleased to witness industry frontrunners selecting this innovative yet straightforward solution to drive the maritime sector towards a sustainable future.”

Riviera Maritime Media’s Maritime Decarbonisation Conference, Europe 2024 will be held in Amsterdam, 24 September 2024,click here for more informationon this industry-leading event